WHEN YOU DEMAND HIGH QUALITY AND ACCURACY, GO WITH........ SPEED CITY !

|

MOPAR |

"IN PROGRESS"

PAGE 3

On these pages you'll see how we create our master models,

so you can see the labor of love that goes into all our products.

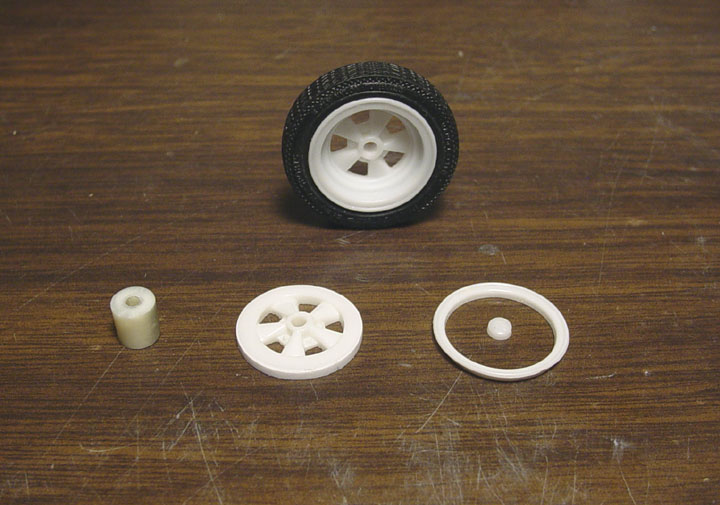

We're creating new S/S Cragar Front Funny Car Mag Wheels with zero off set.

Although the original CRAGAR mag's we were selling previously was a great

mag wheel,

it was made from an amt. rim and didn't match the new mpc. S/S Cragar Mag

Wheels we now sell.

Starting with

an original mpc. Cragar Funny Car Mag Wheel, the mag was cut down the center,

Starting with

an original mpc. Cragar Funny Car Mag Wheel, the mag was cut down the center,

the rim ring was shortened as well as the mag wheel around the spokes.

A

new longer axle

mount was glued to the back, and an mpc. S/S Cragar Hub was glued the the

center of the mag.

Notice:

the original mpc mag wheel in the back ground, this mag just doesn't work

on a funny car tire !

Here is the new S/S CRAGAR

mag wheel compared to the old mpc. funny car mag wheel.

Here is the new S/S CRAGAR

mag wheel compared to the old mpc. funny car mag wheel.

You can clearly see the difference and how much more accurate our new S/S

Cragar Front Mag will be !

We're also adding new "matching inner rims" !

AFX

SUPER STOCK FRONT TIRE

Dunlop

Super Speed

(4x15x26)

Never has there been a nice AFX or Super Stock Tire,

except the Revell "Thunderbolt" front tires.

The problem with the Revell T-BOLT tires, is that there is no tire tread

and once

you scuff them, the tread (or steps) are gone, leaving you with a skinny

front bald tire.

Other

than the tread surface, the side wall and size of the tire is period correct

!

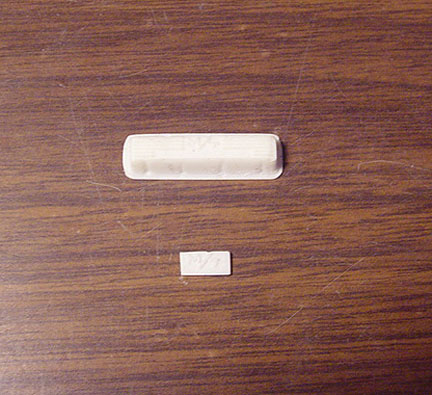

A Revell "Thunderbolt" vinyl tire was cast and a couple resin

duplicates were made.

A Revell "Thunderbolt" vinyl tire was cast and a couple resin

duplicates were made.

The Thunderbolt tire only has lettering on one side (the other side is blank).

So by cutting the 2 tires in half we were able to use 2 lettered sides.

These were then sanded down to 2 inches thick per side.

The new 2- piece tire tread surface was then sanded down smooth.

Originally, we were going to have tire treads done on a lathe, but after

several attempts,

we realized that that wasn't going to work, since tire

tire would get out of round when mounting to the lathe and created a bunch

of problems.

So, we're going back to the way we made the Cheater Slicks....... By hand

!

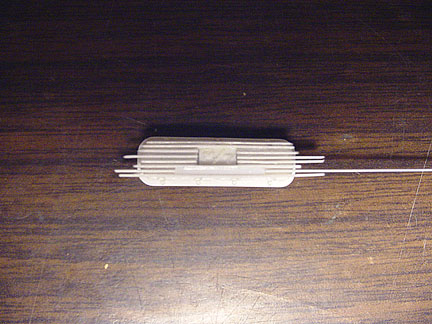

Five strips of .020" x .020" plastic were painstakingly wrapped

and glued around the tire, starting with the outer treads first.

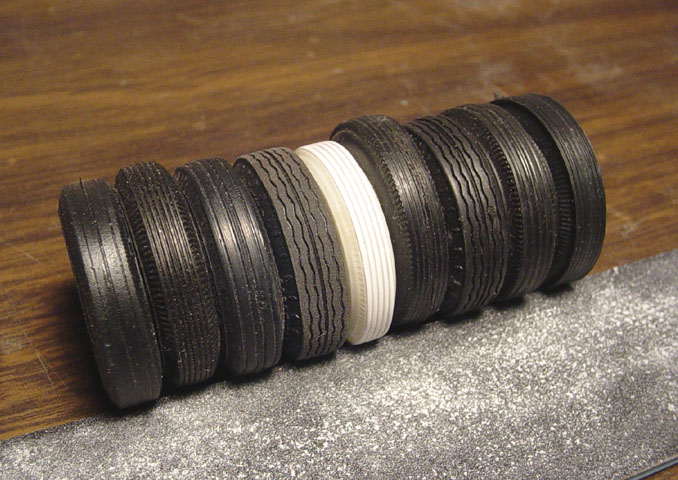

Here is the new "Super Stock Tire" compared to 8 other standard

stock tires.

Here is the new "Super Stock Tire" compared to 8 other standard

stock tires.

Our new tire is much smaller and thinner than any other tire available.........

only 4" wide and 26" tall !

Here it is compared to the original Revell "Thunderbolt" vinyl

tire.

Here it is compared to the original Revell "Thunderbolt" vinyl

tire.

Amazingly, it's a scale 1/4 inch smaller than the original.

Now lettered on both sides and 5 new tire treads !

Now lettered on both sides and 5 new tire treads !

Note: the lack of tire treads on the original.

This new "Super Stock Tire" will be perfect for the Dodge or Plymouth

AFXer's.

This new "Super Stock Tire" will be perfect for the Dodge or Plymouth

AFXer's.

The rear, is a plastic slick that we made our AFX DRAG SLICKS out of......

although this one had glue slop on it.

They look look strange in white, but we wanted to show how they look and fit

on a body.

UPDATE ........ We redesigned this tire to have 6 tire treads !

The reason for adding an extra tread, was that the original treads were only .005 thick and .020 wide, and after a few months

of sitting around while getting other things done...... they melted !..... all that work down the drain.

All the treads were ripped off and 2 new strips of .010 plastic were added (custom made to fit) to fit the width of the tire.

It was then sanded smooth (back down to .005 and each line was hand scribed (with a razor knife) in the new plastic strips to make the 6 treads they have now.

These S/S tires took over the course of 3 years to get into production....... Hope you appreciate them as much as I do.

Jack

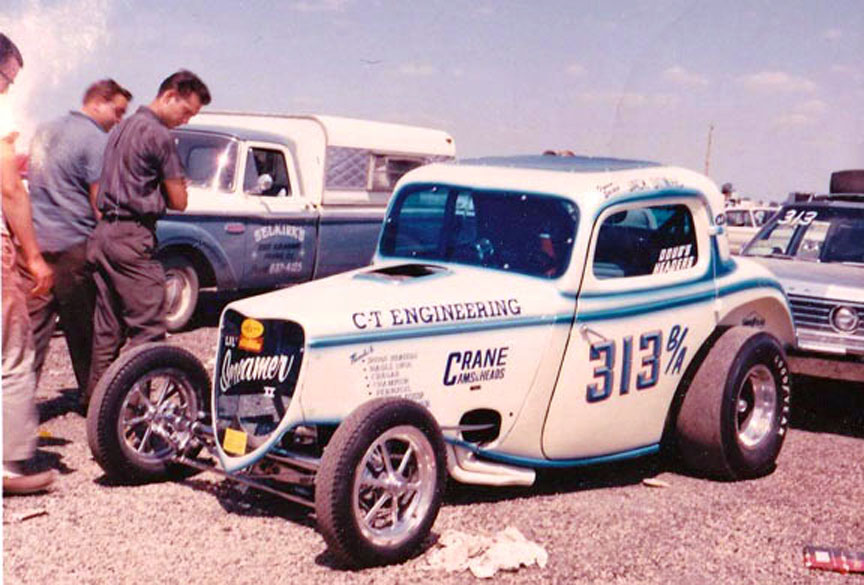

Ditmars'

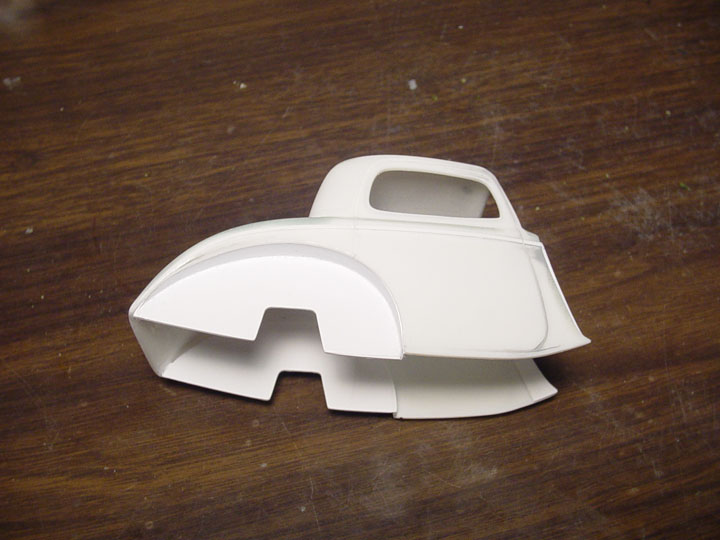

Lil'

SCREAMER

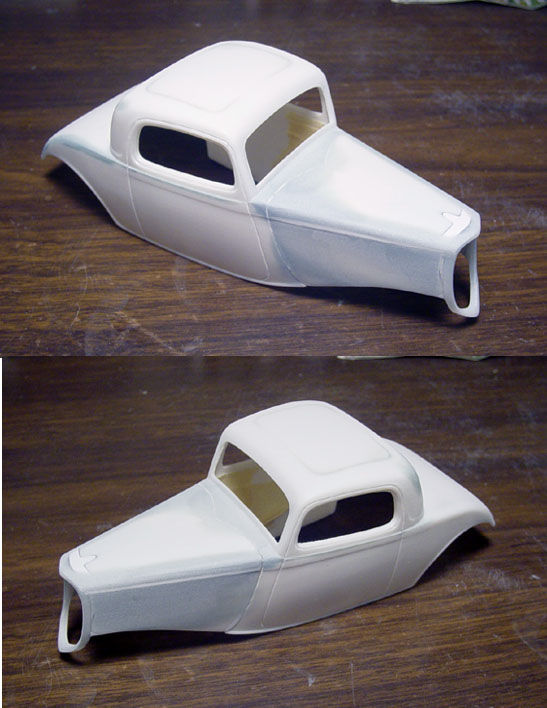

'34 Ford

3-window Coupe

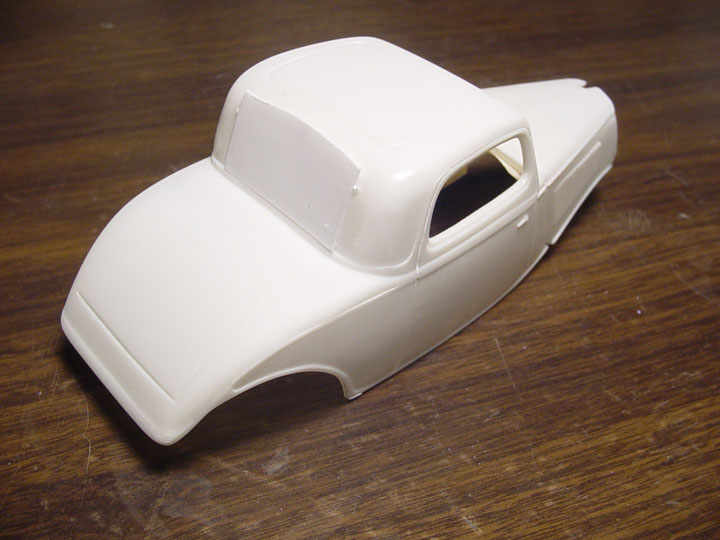

The Revell / Monogram

'34 Ford 3-window Coupe 1/24 scale would have been an easy alteration.

Since

there are no other altered models made in 1/24 scale this model should be made into 1/25 scale.

This will be a challenge!

These are the two best

1/25 scale contenders for this project, but they both have their issues.

These are the two best

1/25 scale contenders for this project, but they both have their issues.

The Revell Snap-Tite has a chopped roof, that will need to be stock height

and the amt '34 Ford has poor body definition,

trim defects and an incorrect

fitting hood.

This model will need a lot of puttying and new trim around all the body

sides.

After wasting time &

money on re-altering the Snap-Tite roof to stock height, we discovered that

the door lines & roof pillar is on a wrong angle.

That project was scraped

and we moved back to the vintage amt '34 Ford kit.

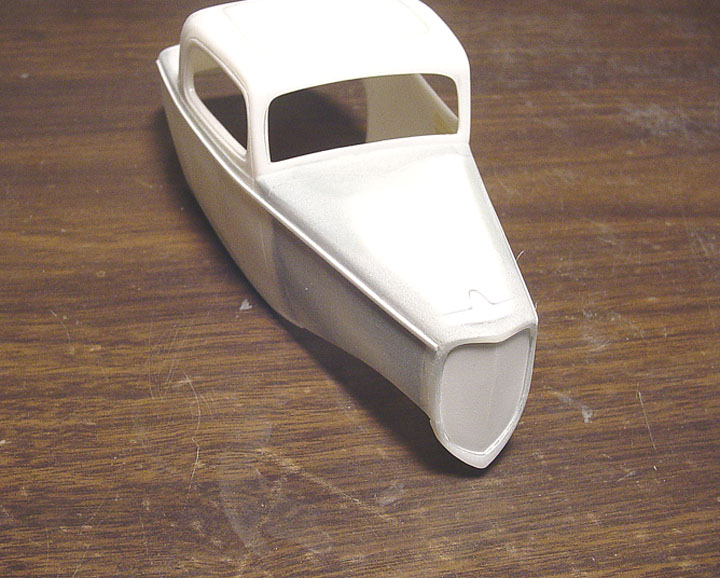

The first thing that needs to be fixed is the rear part of roof.

The first thing that needs to be fixed is the rear part of roof.

The roof

sinks in the middle (a factory flaw) and it will also make the rear pillar

look thicker, the original rear window had no detail anyway.

The poor looking trim was also sanded off from the body and the first application

of putty was used.

The window trim you see

is from an amt '34 Ford 5-window Coupe. This will be fitted into the roof.

The window trim you see

is from an amt '34 Ford 5-window Coupe. This will be fitted into the roof.

The window trim needs to be raised another 2", so plastic square tube

was used.

The window trim needs to be raised another 2", so plastic square tube

was used.

This will need a lot of attention !

Now I'm starting to get annoyed and am looking back at the other purple

'34............ what to do ?

This new rear window trim will look more authentic than all the rest of

the '34 Ford models out there !

This new rear window trim will look more authentic than all the rest of

the '34 Ford models out there !

Comparing this body to photos, the nose piece needs to be re-shaped.

Comparing this body to photos, the nose piece needs to be re-shaped.

The lower half of the

hood needs to be re- sculpted....... more putty !

The lower half of the

hood needs to be re- sculpted....... more putty !

Again, I'm looking back at the purple '34 !

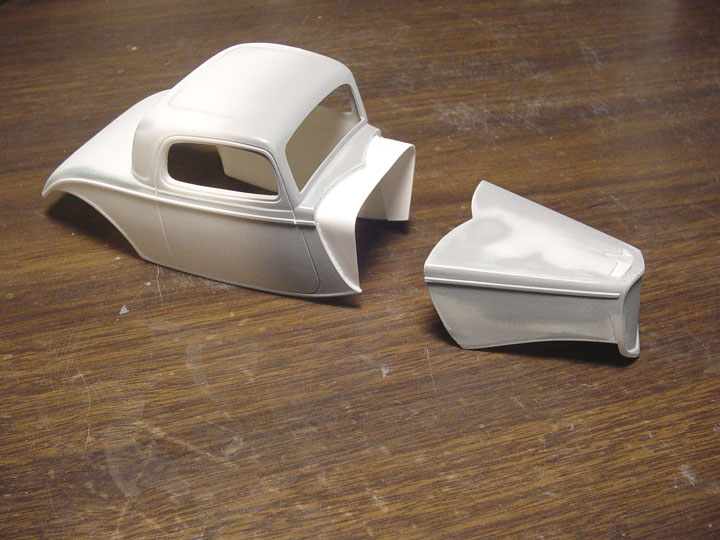

8 coats of putty was applied to the hood, cowl and radiator shell, sanding

in between each coat.

8 coats of putty was applied to the hood, cowl and radiator shell, sanding

in between each coat.

6 scale inches were removed from the radiator shell.

The Caricature Line or / Belt Line was then added with .020 X .040 plastic

strip and a grill filler was installed.

The Caricature Line or / Belt Line was then added with .020 X .040 plastic

strip and a grill filler was installed.

The Grill Filler was made from .010 plastic sheet and will need to be

cut out by the builder (leave a lip for gluing the clear grill).

The Hood was removed from the body and plastic sheet was added to the inside

of the body for a hood support.

The Hood was removed from the body and plastic sheet was added to the inside

of the body for a hood support.

The radiator was re-cut and re-straitened.

The side of the grill was too curved, so it was cut and brought back to

being more straight.

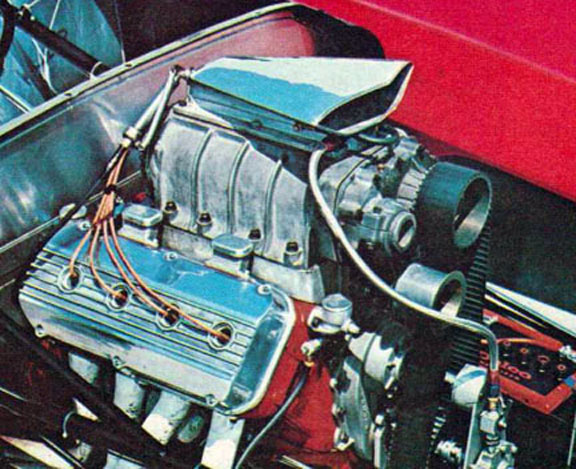

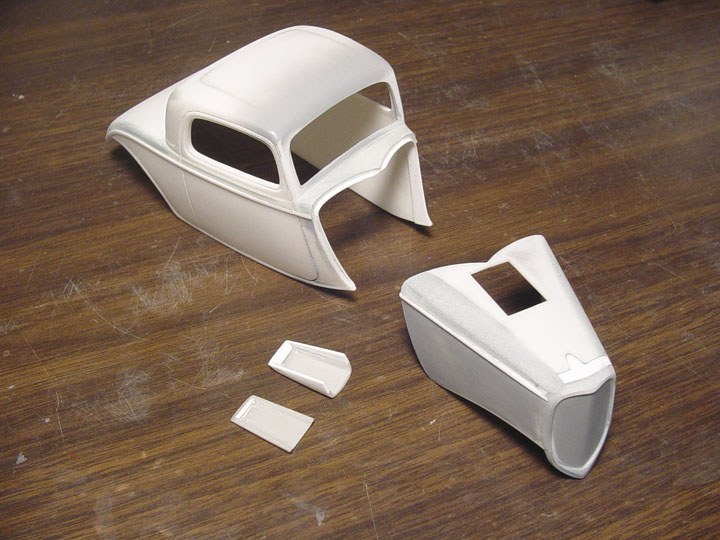

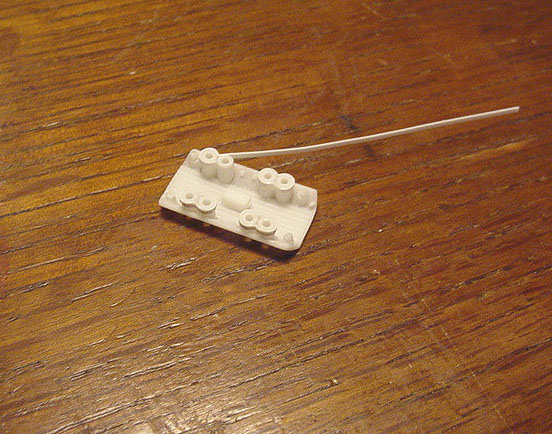

Wanting to add a correct "SCOOP" , I first needed to know the

size of the intake manifold and what small block Chevy Hilborn manifold

to use?

Wanting to add a correct "SCOOP" , I first needed to know the

size of the intake manifold and what small block Chevy Hilborn manifold

to use?

(another part that's missing from our hobby). I found an old Sprint

Car Manifold that could be modified. Studying photos I came up with a perfect

Hood Scoop.

The Hood is finally finished with only some minor flaws to fix.

The Hood is finally finished with only some minor flaws to fix.

The Vintage Hilborn Manifold is for a small block 283 - 350 Chevy.

Unfortunately, I lost all my Small Block Chevy Manifold "In-Progress"

photos.

Going back to the manifold,

16 set screws were added along with some mounting pins.

Going back to the manifold,

16 set screws were added along with some mounting pins.

The Chevy Small Block Hilborn Injection Manifold Master is complete. This

part will be sold separately very soon.

The Chevy Small Block Hilborn Injection Manifold Master is complete. This

part will be sold separately very soon.

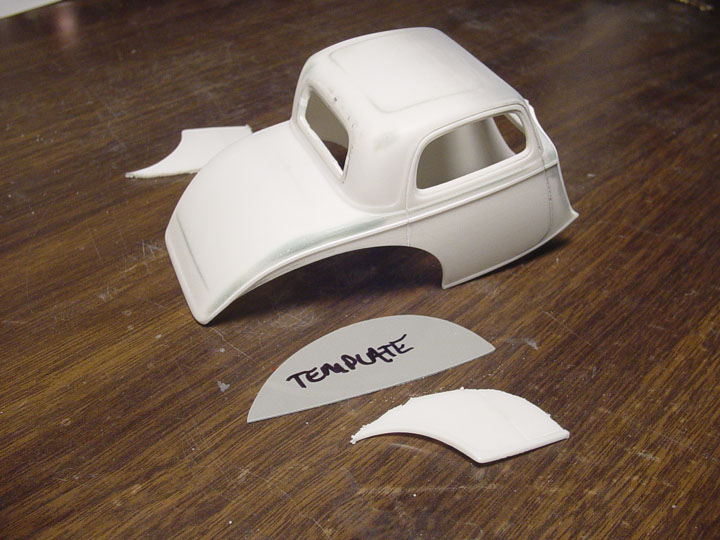

Directing attention back to the body, a template of the shape for the inverted

wheel well was made and used to cut out the original body panels.

Directing attention back to the body, a template of the shape for the inverted

wheel well was made and used to cut out the original body panels.

Using the same template, new back panels were made with .040 sheet and .040

strip was used as the sides.

Using the same template, new back panels were made with .040 sheet and .040

strip was used as the sides.

These will need to be shaped to fit the inside of the body.

The whole time I've been working on this build, I've been noticing the wind

shield.

The whole time I've been working on this build, I've been noticing the wind

shield.

It looks like it has a V- angle, and is more raked than a stock '34 Ford

Coupe........ (see photo).

After reading a new article from Mike Sleeth & Mike Bridgeman's web site, the new owners that are restoring the Lil' Screamer.

After reading a new article from Mike Sleeth & Mike Bridgeman's web site, the new owners that are restoring the Lil' Screamer.

www.lilscreamer2.com

It states

that the window and cowl was replaced with a '37 Ford.

What ? Really ? I wish I would have known that sooner, it would have been

my first alteration, so I could re-shape the '34 hood

to the '37 cowl, this

is really bad news as all the work to the original cowl was a waste of time..... AHHHHHH !

The chrome wind shield ring was removed from the '37.

The chrome wind shield ring was removed from the '37.

The '37 Ford windshield is 6 inches wider than the '34, so rather than split

the window on each side to remove 3" per side,

The '37 Ford windshield is 6 inches wider than the '34, so rather than split

the window on each side to remove 3" per side,

its much easier to add

plastic to the sides and re-shape later.

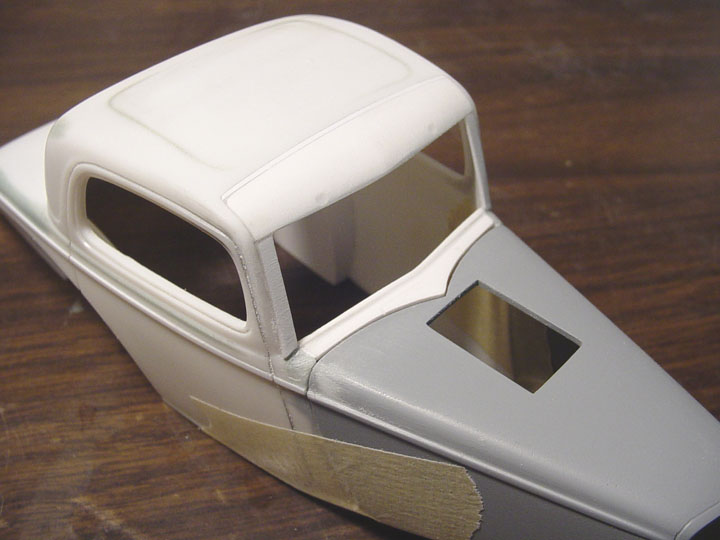

Getting ready for the new '37 Ford wind shield installation.

Getting ready for the new '37 Ford wind shield installation.

Plastic strip was added to the sides of the windshield frame to correct

for the new raked angle.

Plastic strip was added to the sides of the windshield frame to correct

for the new raked angle.

The '37 Ford cowl needed to be re-shaped and the sides of the cowl were

re-puttied.

Another new hood support had to be made......... This is the 2nd time !

Another new hood support had to be made......... This is the 2nd time !

This is a very important process that was overlooked last time.

This is a very important process that was overlooked last time.

The hood, cowl and sides all had to be re-sanded to make it all even, so

the hood will lay down even all away around.

A windshield support is being added......... this was no easy task !

A windshield support is being added......... this was no easy task !

But this way the builder can easily install clear blue tinted windows.

Revell "MISS DEAL" Funny Car (Blue tinted glass) can be used in

case you don't have any

Revell "MISS DEAL" Funny Car (Blue tinted glass) can be used in

case you don't have any

"blue clear" plastic sheet around.

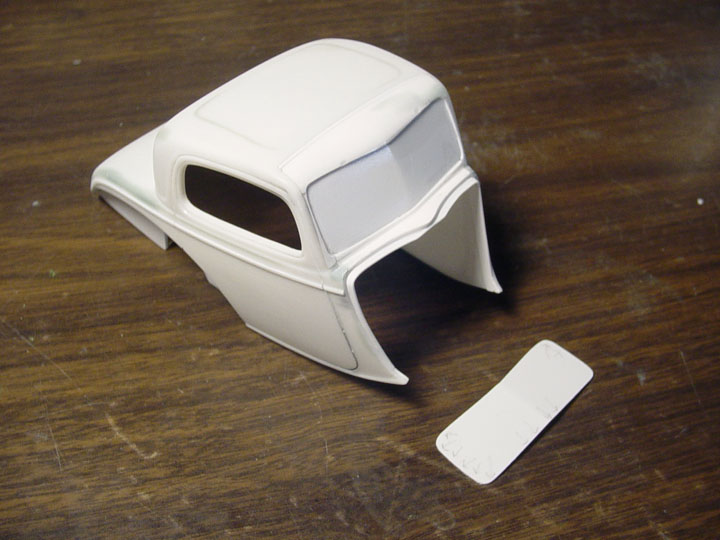

1. New Door

Hinges were installed.

2. New Drip Rails were installed.

3. New Side Window Arches were installed.

4. New Grill lines were scribed in.

5. Hole cut in roof and window support was added.

6. Body was cleaned up, and we have a new Master Model Body.

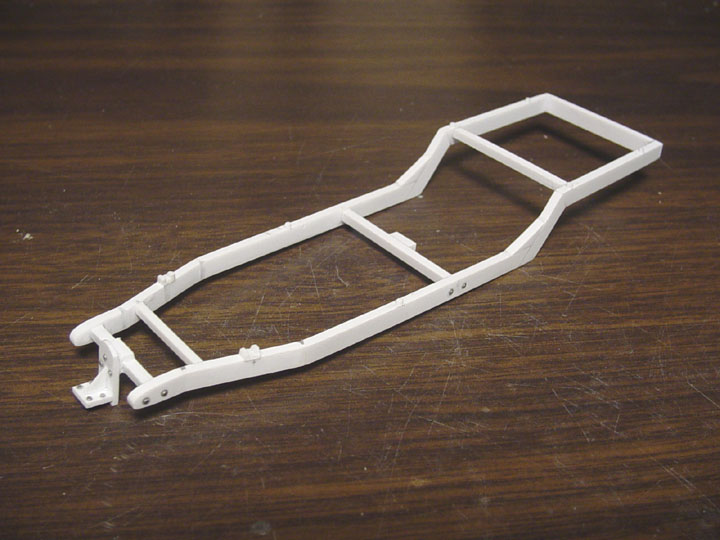

CHASSIS

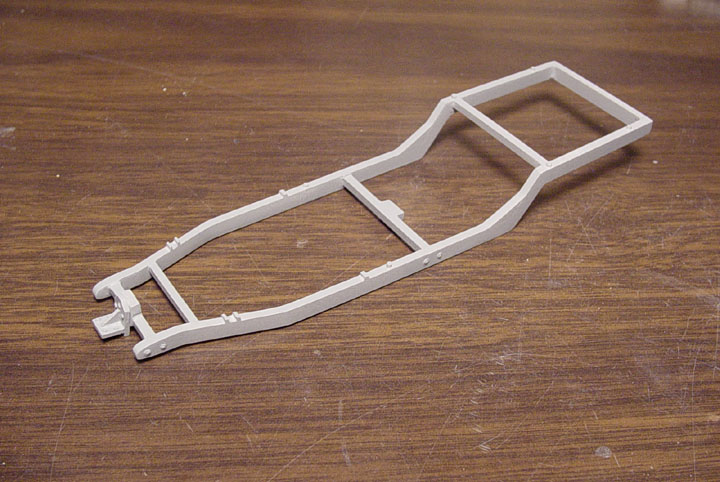

The

Chassis is 100% scratch build from plastic strip of various sizes.

The

Chassis is 100% scratch build from plastic strip of various sizes.

Mike Sleeth donated his time to give all us the measurements from the actual

1:1 Lil' Screamer chassis.

It doesn't get any more accurate than that !

Notice the shackle, nut & bolt details, motor & tranny mounts.

To create a new Racing Seat, we start with a Mustang seat.

To create a new Racing Seat, we start with a Mustang seat.

1. The back, sides & bottom of the seat were thinned & re-shaped.

2. The front section of the seat was cut off and replaced with .040 plastic

strips to create 2 new "Tuck & Rolls.

3. The corners were filled with putty (to make a more rounded transition).

4. New "Seat Piping"was added all the way around the seat using

.010 round rod.

5. Finally, the seat side braces were added.

UPDATE: The Lil' Screamer

had a

belly pan floor made of sheet aluminum,

UPDATE: The Lil' Screamer

had a

belly pan floor made of sheet aluminum,

this can be made from sheet plastic or aluminum sheet from K&S.....

It will not be part of this kit.

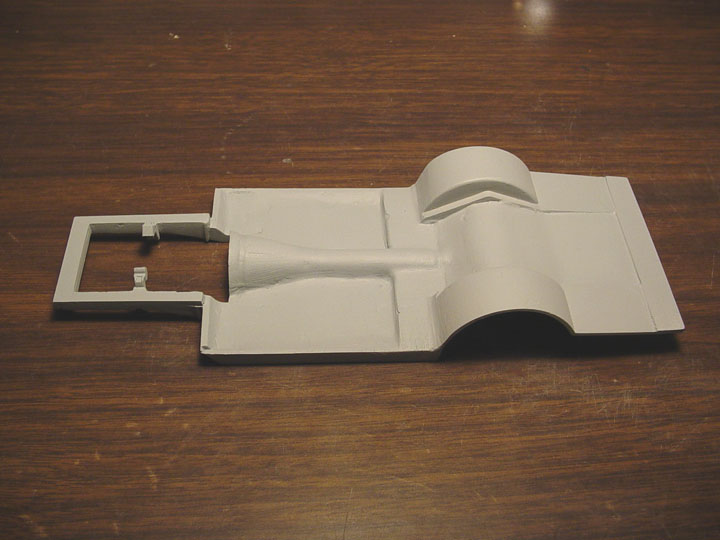

The "Drive Shaft Tunnel" was made from a '67 Mercury Comet Cyclone

tranny tunnel.

The "Drive Shaft Tunnel" was made from a '67 Mercury Comet Cyclone

tranny tunnel.

The "Drive shaft Tunnel" will need to be mounted to the bottom

of the seat and glued

The "Drive shaft Tunnel" will need to be mounted to the bottom

of the seat and glued

to the frame and roll bar brace.

UPDATE: The chassis has been revised

with a raised front shackle, to lower the car.

UPDATE: The chassis has been revised

with a raised front shackle, to lower the car.

This is the third revision to this chassis.......... 3 times the charm I

guess.

But, it is an exact match to the 1:1 car.

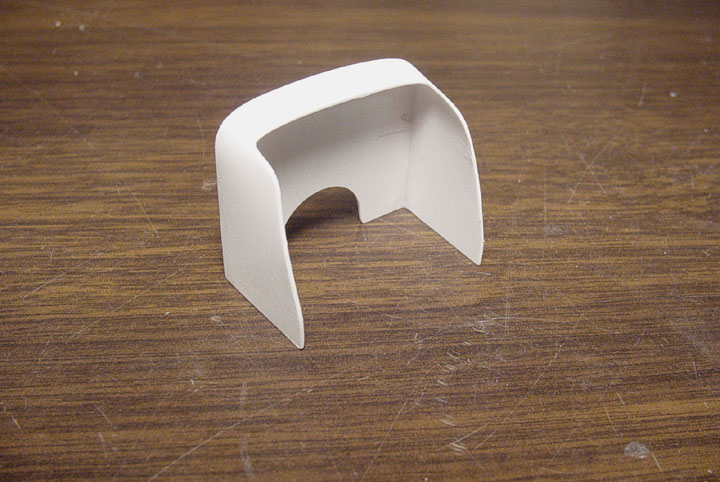

The firewall/ doghouse was made from all sheet plastic !

The firewall/ doghouse was made from all sheet plastic !

The motor mounts and tranny locations are finished.

The motor mounts and tranny locations are finished.

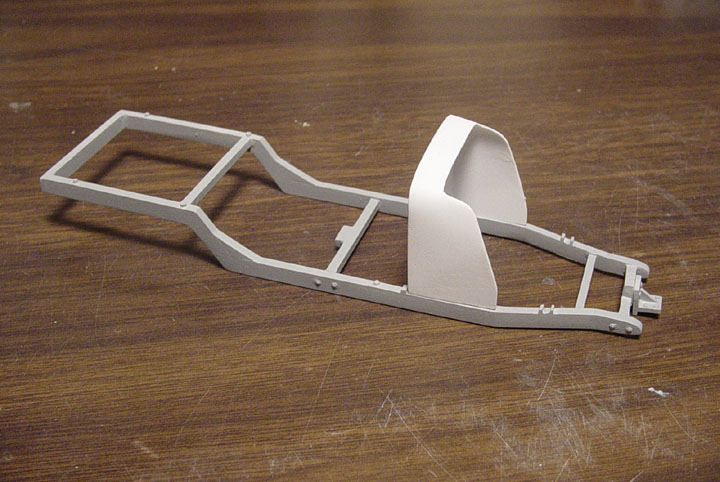

This is how the Seat &

Drive Shaft Tunnel should look when assembling.

This is how the Seat &

Drive Shaft Tunnel should look when assembling.

Glue the back of the seat to a roll bar.

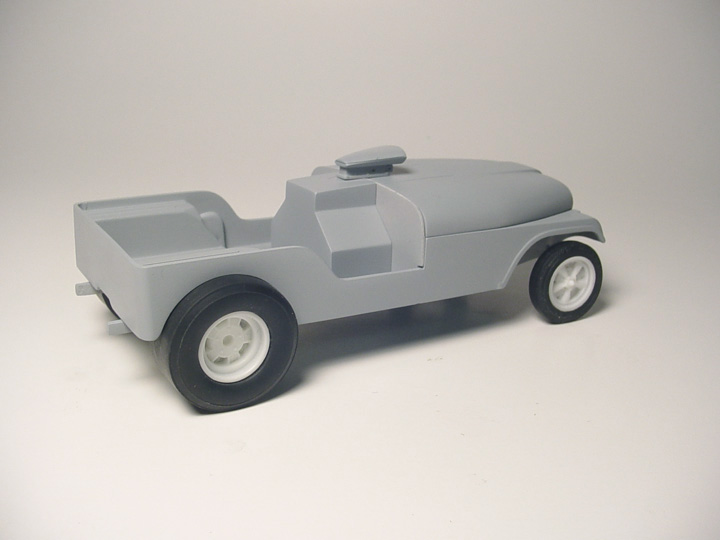

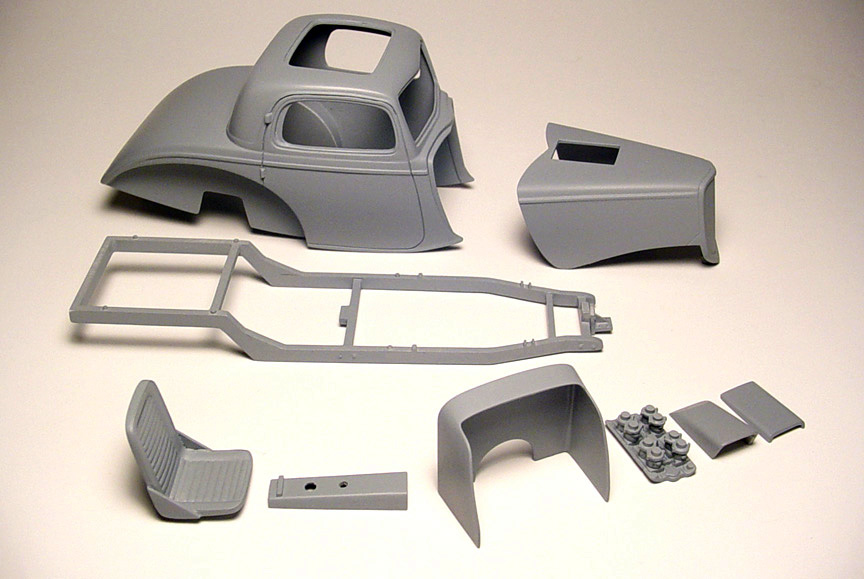

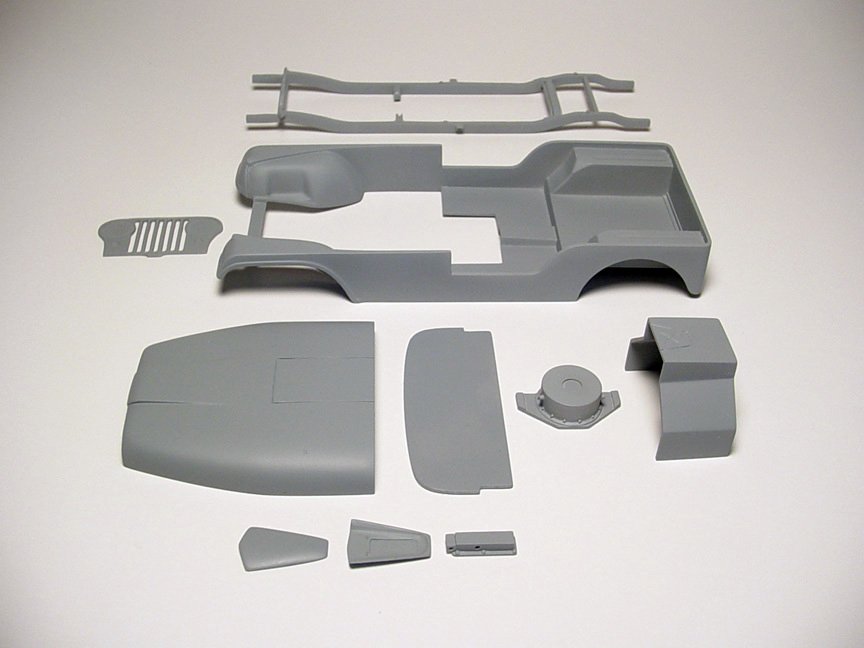

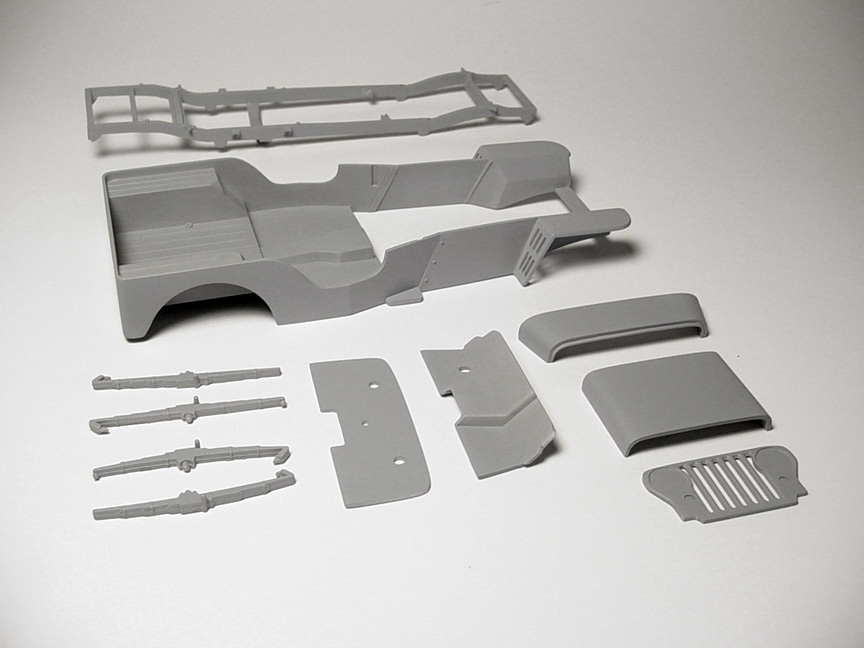

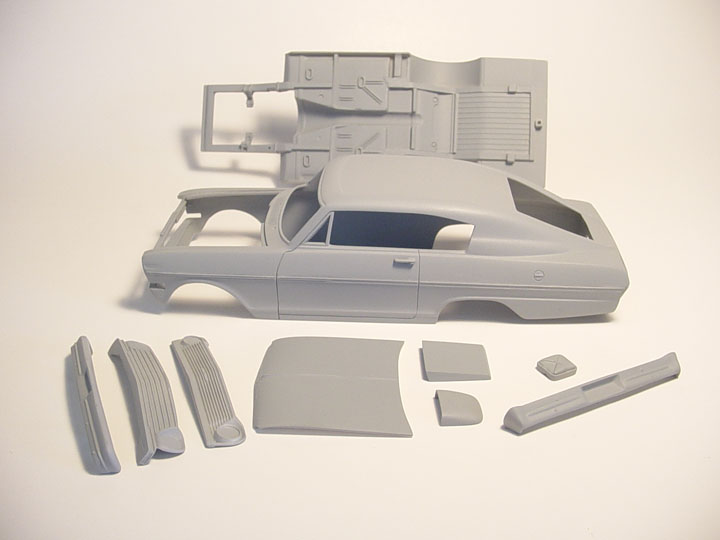

Master Model is finished !

Shown are all the parts that will come with this resin starter kit.

Resin

kit will include: Correct Body, Hood, Frame (with Shackle, roll bar & motor mount locator

pins),

Seat, Drive Shaft Tunnel, Firewall/Doghouse, Hilborn Small Block Chevy Injection

Manifold and 2-piece Hood Scoop.

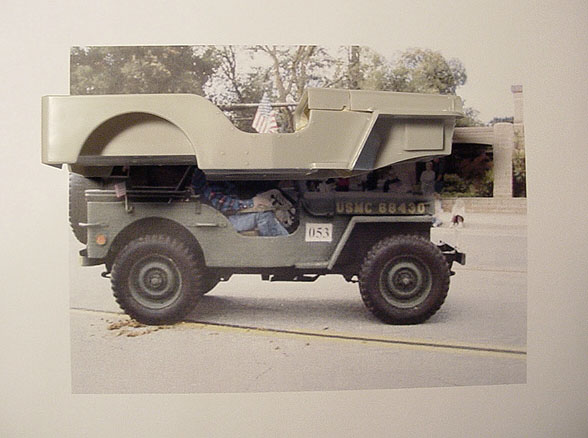

Ed Lenarth & Roger

Wolford's

"SECRET

WEAPON" ARMY JEEP

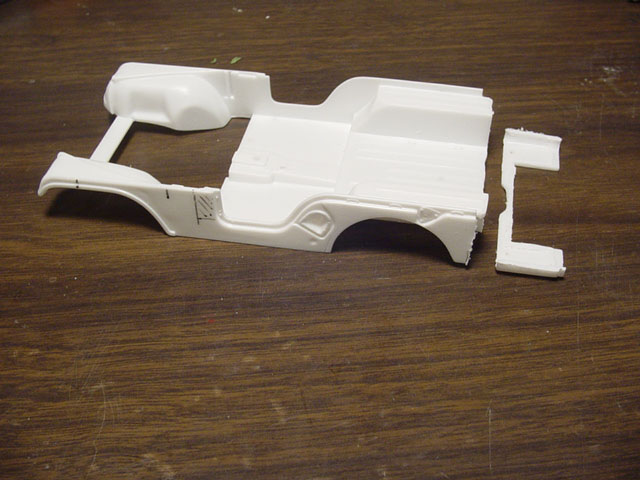

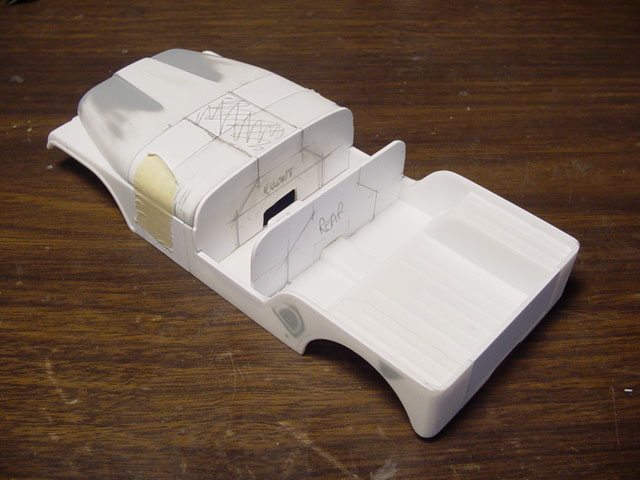

Starting

this project with an amt/ertl Daisy Dukes CI Jeep.

Starting

this project with an amt/ertl Daisy Dukes CI Jeep.

Comparing it to the Secret Weapon Funny Car and some 1965 Stock Jeeps,

I

noticed the rear was too long and there wasn't enough room for decal lettering

on the side of the door area for the Secret Weapon Jeep,

So plastic strip

was ran up the front of the wheel well and the rear of the stock wheel well

was cut back to shape.

This set the wheels back another inch and a 1/2.

Also:

The trunk of the jeep was way too long, so 6 scale inches were cut and removed

from the rear.

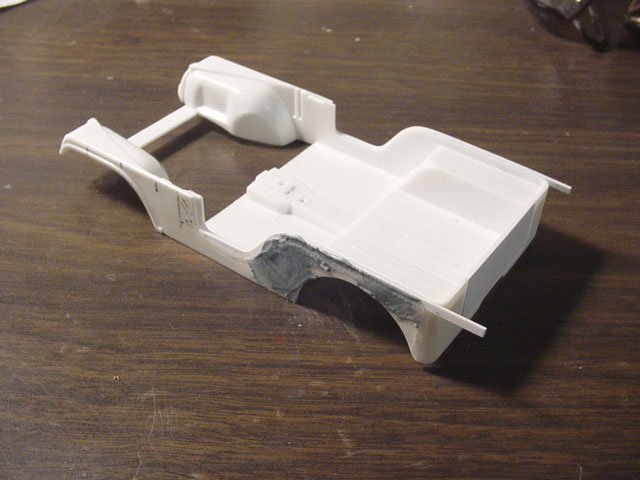

The recess' on the sides all needed to be filled in, along with adding sheet

plastic to the top edge of the body.

The recess' on the sides all needed to be filled in, along with adding sheet

plastic to the top edge of the body.

The tail gate was filled in using .080

plastic sheet.

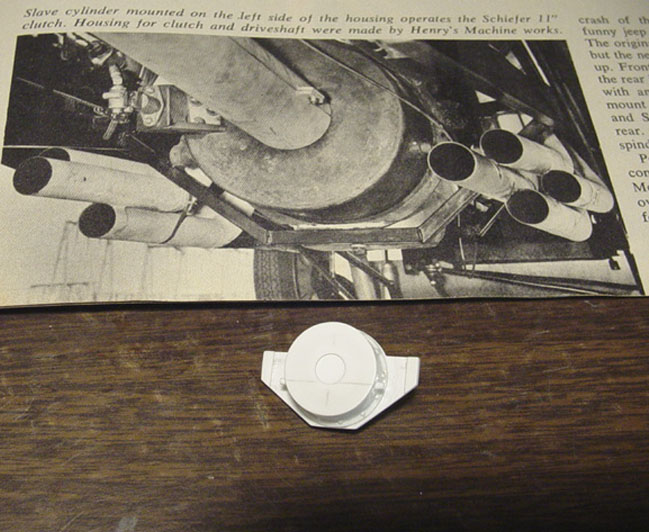

After reading an article

from Popular HOT RODDING Nov.1966,

After reading an article

from Popular HOT RODDING Nov.1966,

it makes mention of the original Wheelbase

measuring 102"........ I used these measurements for all the Wheel

Base alterations.

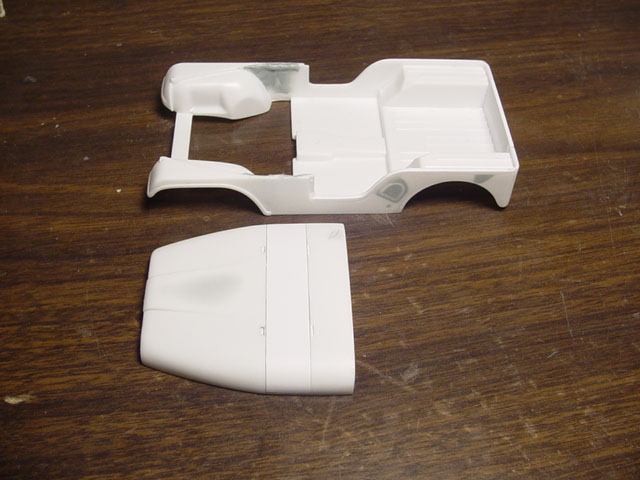

The original cowl being 12 scale inches, another 12" plastic sheet

was then added to the mid-section of the hood and the cowl,

to give it

the stretch it needed....... and putting it in the middle added strength,

so the hood

will retain its shape.

The original hood and cowl were too wide for the body at the rear,

The original hood and cowl were too wide for the body at the rear,

so a pie shaped 4" cut was removed and the 2-pieces were re-glued

(although a filler strip was added to the center of the cuts).

All other holes were filled in and a plastic strip was added the the rear

of the hood.

The hood is made up of 13 separate pieces, all reshaped and sanded smooth.

The hood is made up of 13 separate pieces, all reshaped and sanded smooth.

The front of the door entry was cut up to the bottom of the floorboards,

this made sense, since the firewall would end at the front of the door.

The front of the door entry was cut up to the bottom of the floorboards,

this made sense, since the firewall would end at the front of the door.

After reviewing the wheelbase, it being 102", the body needed to

be stretched another 18"..... this was re-checked using tires and

mag wheels for accuracy.

The front of the fenders needed to be thicker, (as you could see a gap

between the hood and the fenders) so Evercoat putty was used.

The bottom of the doors were too short also (keeping in mind the Champion

sticker & Driver/Owner names needed to fit),

another scale 2"

were added using. 060 X .080 plastic strip.

A firewall was made from .060 plastruct sheet, a secondary firewall was

made for the basis of the rear section of the Dog House.

A firewall was made from .060 plastruct sheet, a secondary firewall was

made for the basis of the rear section of the Dog House.

The sides of the Dog

House were made with .040 plastruct sheet.

The sides of the Dog

House were made with .040 plastruct sheet.

The Dog House is now starting to take shape.

The Dog House is now starting to take shape.

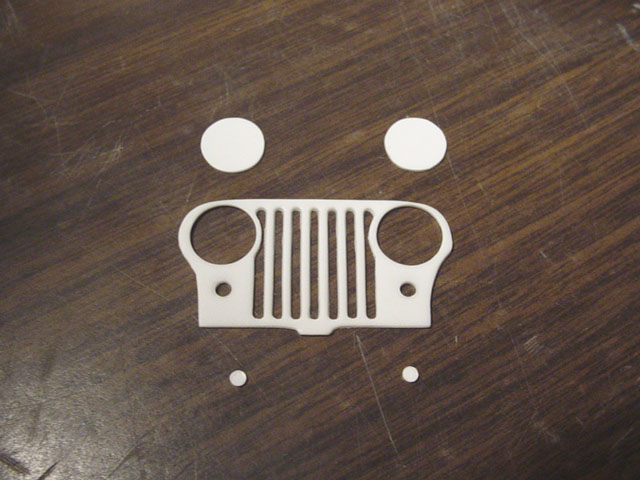

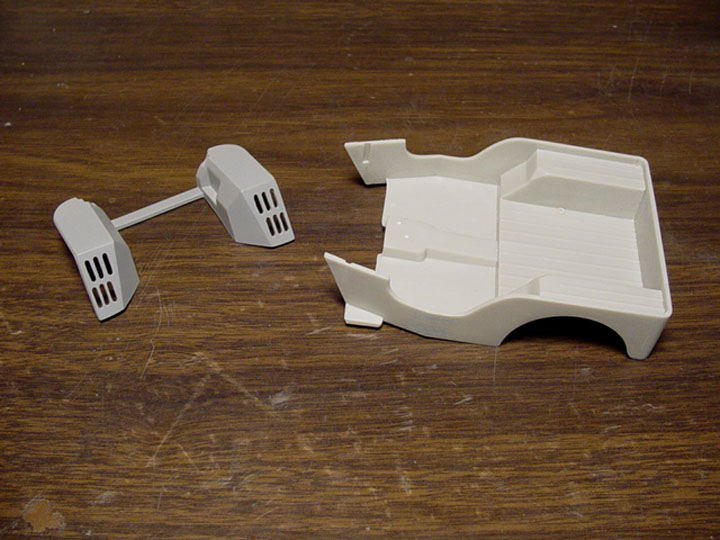

The head light buckets were drilled out and the original holes of the

signal lights were filled in with super glue as a quick filler.

The head light buckets were drilled out and the original holes of the

signal lights were filled in with super glue as a quick filler.

Now, for some reason, the original grill was flat in the front and rounded

in the back (a factory flaw).

The grill was reversed, so the the rounded edges now facing front.

An all new grill with blocked-out head lights and marker lights.

An all new grill with blocked-out head lights and marker lights.

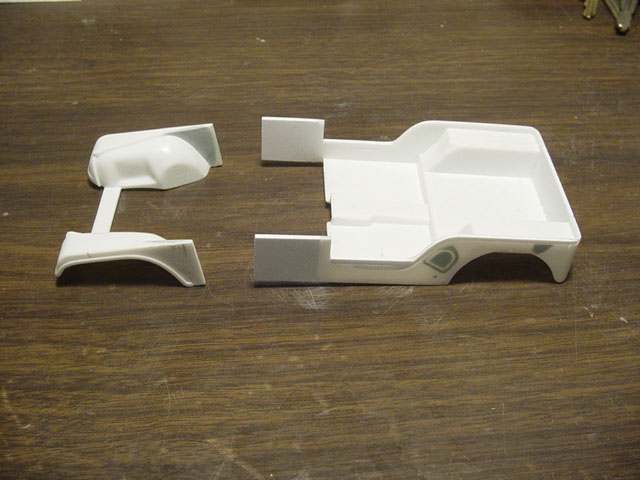

CHASSIS

The original

chassis was cut in two, so we can add the 18" stretch to match the

body.

The original

chassis was cut in two, so we can add the 18" stretch to match the

body.

This will be done using 2- pieces of .060 plastruct

strip,

super gluing them together to get the thickness of the original

frame rails and then adding 18 scale inches to both sides.

I wanted to add motor mounts and tranny mounts on the new frame to fit the

Miss Deal 392 Hemi,

I wanted to add motor mounts and tranny mounts on the new frame to fit the

Miss Deal 392 Hemi,

but after searching for a good "DIRECT DRIVE HOUSING"..........

I couldn't come up with a correct one, in any model kit.

So it was decided to build a new correct one based

on a "HENRY'S DIRECT DRIVE BELL HOUSING".

This

is another part that is missing from our hobby!

This

is another part that is missing from our hobby!

We will be adding it to the production line as a single part very soon.

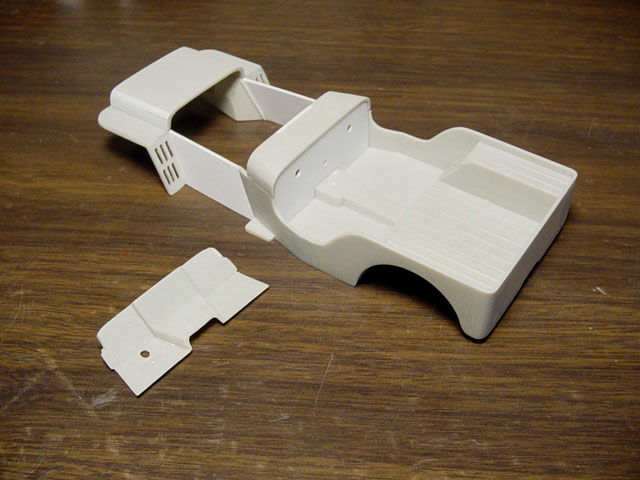

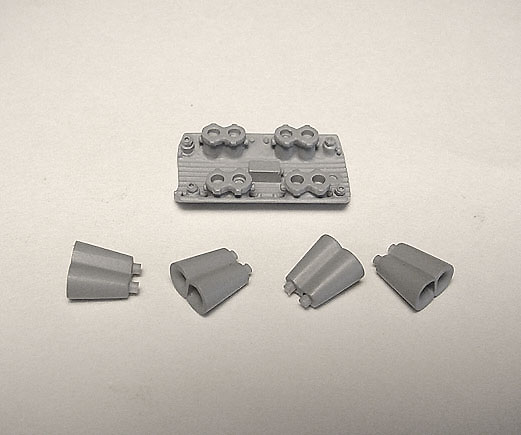

SCOTT "Super Scoop" INJECTION

The Secret

Weapon Jeep uses a "SCOTT INJECTOR"

This new piece will be made and sold separately.

Starting with a Scoop

from the Revell Tony Nancy 22 jr. kit, it was completely re-shaped.

Starting with a Scoop

from the Revell Tony Nancy 22 jr. kit, it was completely re-shaped.

The Injector unit was

created with plastic square tube and toped off with actual nuts & bolts

for realism !

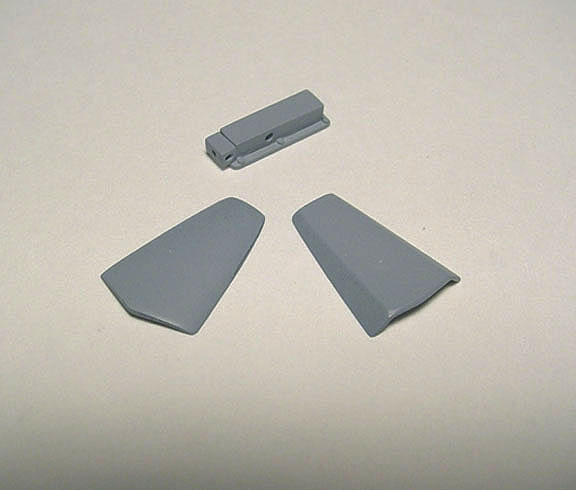

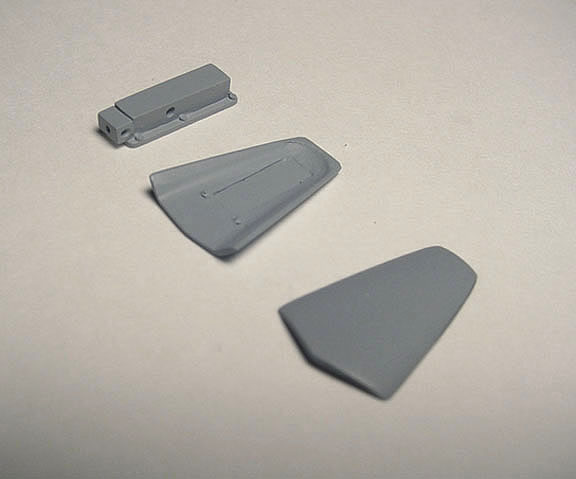

Here's

all the parts for the "SCOTT INJECTOR" and will come with this

model.

Here's

all the parts for the "SCOTT INJECTOR" and will come with this

model.

It will

also be sold as a separate piece on the web site !

The Master Model is finished!

Model

is now Available !

#SC-

61

Gene Conway's

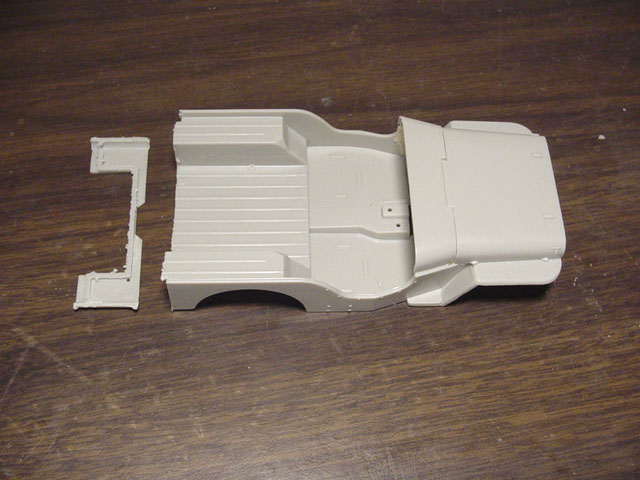

C&O "DESTROYER" NAVY JEEP F/C

We're starting out with

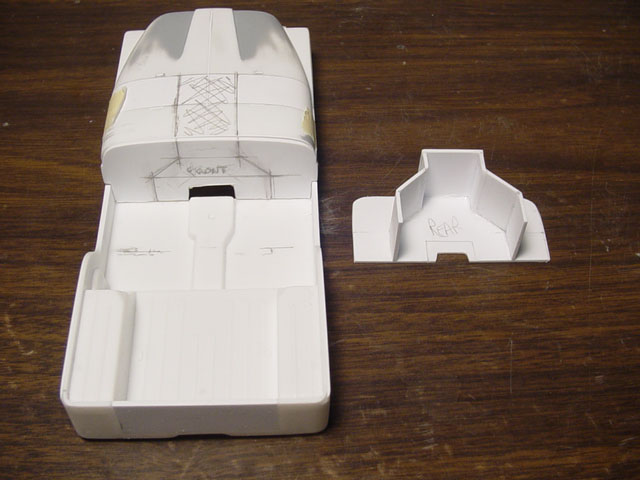

an amt/ertl Hogan's Heroes World War II Jeep.

We're starting out with

an amt/ertl Hogan's Heroes World War II Jeep.

After doing research for Jeeps on the internet, it was determined that this

Hogan's Heroes Jeep was based on a Willys M38

*The M stands for Military*

It's obvious that the rear of the bed and 1/4 panels were too long even

for the stock Jeep...... (see photo).

4 scale inches were removed

from the rear.

4 scale inches were removed

from the rear.

Now the stock Jeep body looks correct compared to the original body and

the full size Jeep !

Now the stock Jeep body looks correct compared to the original body and

the full size Jeep !

The front clip was removed from the body, the "Speed Holes" on

the fenders were carefully measured and rounded out with a round jewelers

file.

The front clip was removed from the body, the "Speed Holes" on

the fenders were carefully measured and rounded out with a round jewelers

file.

All seat mounts and injector marks were removed from interior floor,

as well as filling in the gun mounts on the side.

The cowl was filled in with plastic and then a drip rail was added to the

front of the cowl.

The cowl was filled in with plastic and then a drip rail was added to the

front of the cowl.

The headlight holes were filled in with .010 plastic sheet.

the marker lights were ground down, holes were drilled and the plastic sheet

was counter sunk to match the headlights.

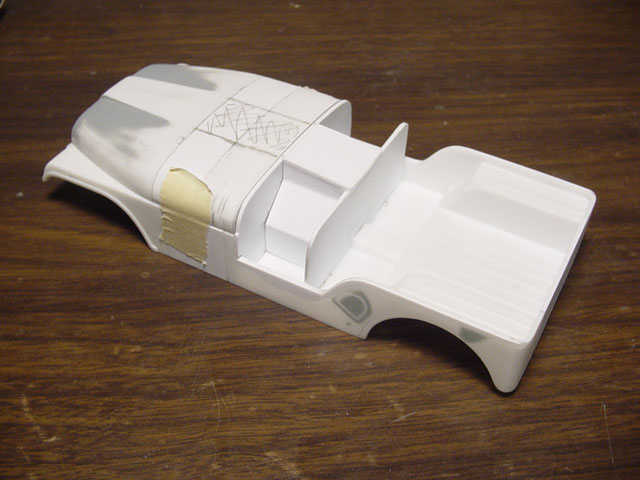

To make the Destroyer hood, it needed to be shorter, narrower and also had

to be straitened, as the stock Jeep hood has a raked shape.

To make the Destroyer hood, it needed to be shorter, narrower and also had

to be straitened, as the stock Jeep hood has a raked shape.

The Destroyer

Jeep Funny Car hood is completely square.

So, the hood was cut in half and 3 1/2 scale inches were removed from the

front and 8" were taken from the rear of the hood.

Plastic strip was added to the sides of the hood, to match the contour shape

of the grill.

The hood is supposed to go over the grill, but because of the thickness,

it looks way out of scale.

You can use this hood as a template if you want to add real aluminum sheet,

it could then hang over the grill.

All pedals and wires were removed from both sides of the Firewall and a

secondary Firewall was made from

All pedals and wires were removed from both sides of the Firewall and a

secondary Firewall was made from

0.40 plastic sheet, with all roll bar holes

& steering wheel hole in the correct displacement.

The article states the

car was stretched 30", so 30" body panels were added using .040

plastic sheet.

Which would give the body a 104" wheelbase.

The article also states that the wheelbase is 110", so there is a discrepancy about the measurements here.

If the wheelbase is 110", the body would need to be stretched by 36".

After reveiwing this photo,

it doesn't look like they altered the fenders and compared to the master 1/25 scale body I'm working with,

I'm going with the 30" stretch as it looks to be more accurate.

The grill didn't fit properly, so 7 new pieces of plastic strip were added

to The front of the grill around the fenders.

The grill didn't fit properly, so 7 new pieces of plastic strip were added

to The front of the grill around the fenders.

The battery recess was also filled in with plastic sheet.

CHASSIS

The original Jeep frame was stretched 30" to match the body.

The original Jeep frame was stretched 30" to match the body.

The back bumper supports were removed, along with the original motor mounts.

Using a Revell 392 Miss Deal Hemi, it was determined where the motor mounts

and transmission bracket needed to be relocated.

The back of the frame rails needed to be raised, by using plastic strips

to fill the gaps, and the spring brackets

were cut off and re-set back to

the raised frame rails. The ends of the frame rails were all boxed in using

plastic strip.

You can see here how nice the new frame fits.

You can see here how nice the new frame fits.

We will also be adding the springs from the Hogan's Heroes Jeep, so no donor

kit will be needed !

Just add your own rear end and front dropped axle.

After all the major body work, we went back to put in bolt heads on the

fabricated panels.... a nice extra detail !

After all the major body work, we went back to put in bolt heads on the

fabricated panels.... a nice extra detail !

THE MASTER IS FINISHED

Model

is now Available !

#SC-

60

7"

CHEATER SLICKS

(

M&H Racemaster Super Stock )

&

9"

CHEATER SLICKS

( M&H

Racemaster Super Stock )

No aftermarket or model company has ever made a correct 7" or 9" Cheater Slick....... until now !

Starting

with an old Racemaster Super Stock 9" plastic drag slicks from an unknown

kit ?

The reason was clear, it not only has the correct 9" width, but is

very rare and would make a great contender for a

new cheater slick, and its not quite a Pie Crust type slick, but it does

have nice side wall line detail !

The surface was sanded down smooth & Straight, and to retain a 30"

diameter after we add 0.10 thick plastic strip.

Two .010 X .125 Evergreen plastic strips were added to each side, carefully

glued on with plastic cement.

A center strip of 0.80 Evergreen strip was added to the center, creating

2 small empty lines...... the new Cheater lines.

To create the 7" Cheater Slick, we used the other pair of slicks and

cut it down the middle, removing 2 scale inches from the center,

To create the 7" Cheater Slick, we used the other pair of slicks and

cut it down the middle, removing 2 scale inches from the center,

after carefully

measuring around all the surface, the 2 - pieces were glued together.

.010 X .080 was used for each side, then a piece of .010 X .100 was used

in the center, creating new empty Cheater lines.

Each

Cheater line was re-scribed to perfection.

A

special thanks to Dennis Havlicek for his extensive research on NHRA approved

Cheater Slicks !

7" Cheaters

7" Cheaters

9" Cheaters

9" Cheaters

M/T BIG BLOCK CHEVY VALVE COVERS

"Dirty Don" from reliable resin has copied these M/T BBC Valve Covers that I created here,

and is now selling them on his Facebook page.

"Don't Support Resin Piracy"

Be an educated buyer.... Please read !

Click logo

Starting with

an old MOROSO CHEVY big block valve cover ( from an unknown kit ? )

Starting with

an old MOROSO CHEVY big block valve cover ( from an unknown kit ? )

it had the correct size and bolt pattern. The top of this valve cover was

sanded flat with a slight angle.

This valve cover (on top) was considered a BBC, (some resin company's are

selling this valve cover as a Big Block,

This valve cover (on top) was considered a BBC, (some resin company's are

selling this valve cover as a Big Block,

but its way too narrow, too short,

too thin and lacks major details !

The M/T scripts

were cut out from it, and are going to be added to our new BBC VALVE COVER

MASTER.

Now comes the hard part

!

Now comes the hard part

!

After sanding down the M/T logo to fit flush, I wanted to use 0.10 X 0.10

plastic strip for the cooling fins,

but neither Plastruct or Evergreen made a strip that small, so I had to use .010 X .040, the. 010 side was glued to the Valve Cover to create

the fins.

These fins will be sanded down to be .010 tall.

A piece of .010X. 040 was applied on its side to be used for the center

flat spot.

The

master is finished !

The oil cap plug and 427 script plug was added by

hollowing out tubing and adding another smaller tube slightly lower.....

although I didn't add the 427 letters (you wouldn't be able to read

it anyway).

This is the only accurate M/T BBC valve cover ever made..... I Guarantee it !

FIRESTONE DRAG 500 SLICKS

These

Slicks are being designed by Ron Ramsey & Scott Kapellusch

Ron Ramsey had some original Johan Firestone Drag 500 Slicks, the problem

is.....

is that they are lettered FIRESTONE one one side, and GOODYEAR on the other.

Another problem is that they are too small in diameter and have no side

wall detail.

We

wanted to create an all new correct FIRESTONE DRAG 500 SLICK

lettered on both sides with correct diameter and side wall detail !

These Slicks will fit a stock wheel well on any Barracuda, Charger, Dart, Road Runner, Etc.

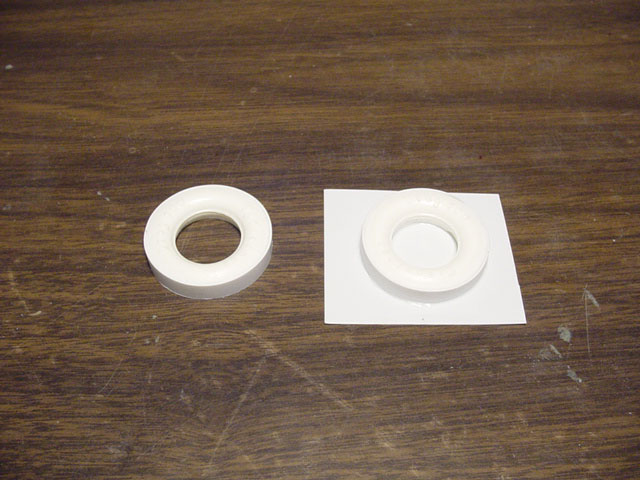

Ron cast the FIRESTONE

500 side from the Johan Slicks.... (as they had GOODYEAR on the other side).

Ron cast the FIRESTONE

500 side from the Johan Slicks.... (as they had GOODYEAR on the other side).

The slicks were too small in diameter, so I added .020 plastic strip around

the surface of the tread area.

This not only did this makes it a bigger diameter, but will also serve as

the detail edge of the slick.

.010 plastic sheet was added to one side of the slick ( this is to aid in

the molding process).

.010 plastic sheet was added to one side of the slick ( this is to aid in

the molding process).

The two sides of the FIRESTONE slicks were glued together, making sure it

was 10.50 all around.

The two sides of the FIRESTONE slicks were glued together, making sure it

was 10.50 all around.

Ron and I agreed, that the slick would be cool to have a curved crown effect

on the tread surface !

At first I tried

to use masking tape with different sizes to create a bulge effect, but it

didn't work out well, so the slick was taped off

on both sides of the side wall and a home made tool was made from plastic

sheet to be used as a putty spreader.

After some carefully sanding, here is the new crowned surface.

After some carefully sanding, here is the new crowned surface.

The Slick was primed, checked for imperfections and re-worked, all work

was done under a magnifying glass !

The hard copy is ready to be molded in rubber.

The hard copy is ready to be molded in rubber.

THE MASTER IS FINISHED !

ENDERLE

FUEL INJECTION CHEVY MANIFOLD

(with Ram Tubes)

Enderle Chevy Manifold & Ram Tubes were never offered in model form.......... until now !!!

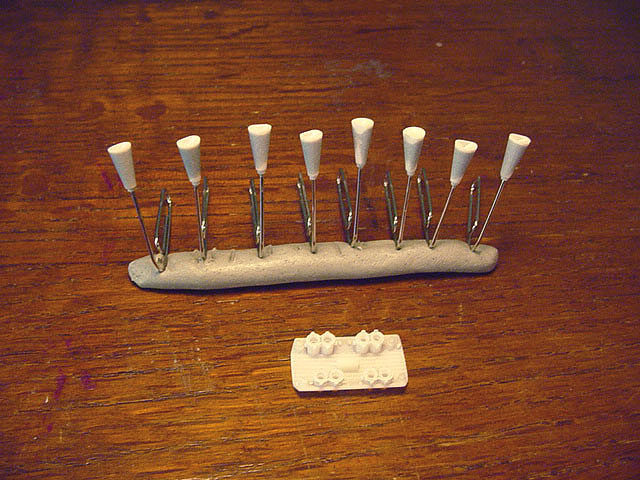

Starting with our Chevy Hilborn

Manifold, the injectors were removed and new holes were drilled for plastic

tubes (to be used as straight tube injectors).

Starting with our Chevy Hilborn

Manifold, the injectors were removed and new holes were drilled for plastic

tubes (to be used as straight tube injectors).

The tubes were cut to size and

tension rings were added with .010 plastic strip.

The tubes were cut to size and

tension rings were added with .010 plastic strip.

All nut & screw heads were added, along with Throttle end caps.

All nut & screw heads were added, along with Throttle end caps.

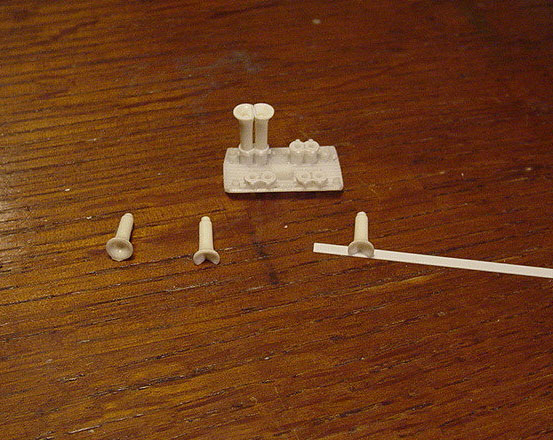

Starting with some old plastic

stacks, one side of each tube had the flare cut off and .010 plastic strip

was added.

Starting with some old plastic

stacks, one side of each tube had the flare cut off and .010 plastic strip

was added.

This is so the tubes can be fit flush together.

So here's were it gets tricky......

the stacks we show here are straight tubes with a flare at the end, our

new "Ram Tubes" need to be cone shaped.

So here's were it gets tricky......

the stacks we show here are straight tubes with a flare at the end, our

new "Ram Tubes" need to be cone shaped.

So the stacks were mounted to paper clips and puttied along the sides of

the tube (this is so it can be handled while puttying & sanding).

this was not easy and one mistake would have been disastrous !

Here are the new "cone shaped"

tubes after they were sanded smooth.

Here are the new "cone shaped"

tubes after they were sanded smooth.

The tubes were glued together,

but were too long, so they were measured and cut.

Not shown, but the tubes also had to be re-puttied between the tubes, for

a better look.

Here are the new "RAM TUBES" and finished Enderle Manifold.

Here are the new "RAM TUBES" and finished Enderle Manifold.

99 separate parts were used to

create this Enderle Manifold & Ram Tubes.

99 separate parts were used to

create this Enderle Manifold & Ram Tubes.

12 pieces had to be filled with putty, that's 111 steps to make this master.

THE

MASTER IS FINISHED !

( Ram Tubes will be 4 separate pieces )

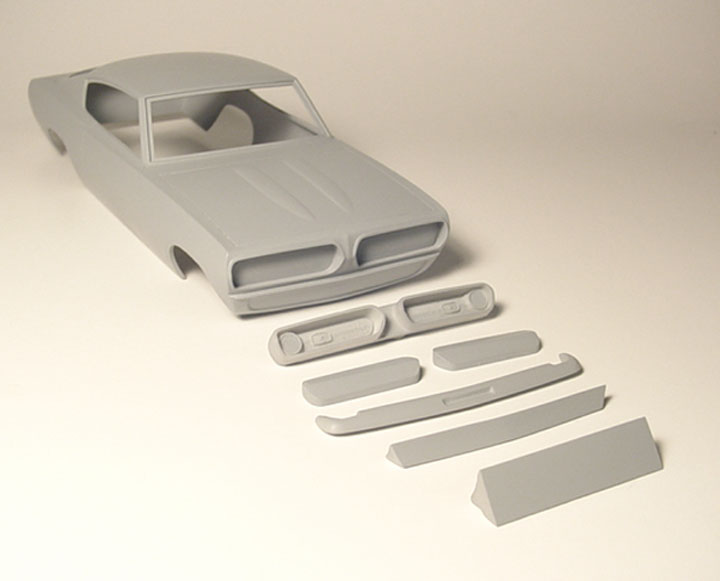

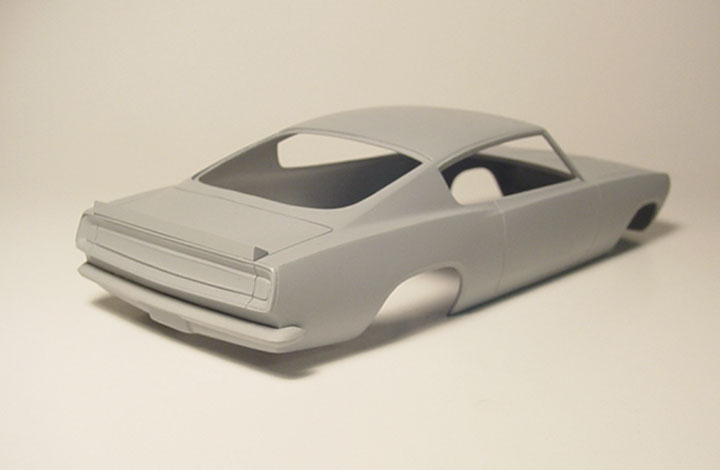

'67-'68

BARRACUDA FUNNY CAR

THIS

WILL BE THE FIRST '68 BARRACUDA FUNNY CAR EVER MADE !

Our

goal is to give you an accurate body to represent a true '67-'68 Barracuda F/C

Body

as the Polar Lights Barracuda F/C body is not correct, not even for what they show on

their box art !

The Polar Lights Body is a Stretched, Flattened, '69 Cuda body. It also has

inaccurate proportions.... Sad but true !

BODY WORK

I took these photos of the Polar Lights Cuda Body and our '68 Barracuda

stock body,

I took these photos of the Polar Lights Cuda Body and our '68 Barracuda

stock body,

you can see the changes in body shapes. Notice the front 1/4

panels are sloped on the stock '68 body,

notice the roundness on the stock

'68 body, notice the POWER BULGES on the stock '68 hood, notice the Polar

Lights body is a '69 Barracuda !

After removing all the Emblems,

Marker Lights, Wiper Blades, Door Handles & all Body Trim.

After removing all the Emblems,

Marker Lights, Wiper Blades, Door Handles & all Body Trim.

The

Louver Holes were taped off.

this is so there will be no mistakes when we fill it with putty.

The putty was sanded down to the tape, again, so NO

mistakes are made.

The putty was sanded down to the tape, again, so NO

mistakes are made.

The Vent holes were done the same way !

The Vent holes were done the same way !

I had to re-tape & re-putty the power bulges, to give them more of a

rounded arch, as I wasn't happy with the first result's.

The front wheel alteration was started by putting

the bumper on to get an idea of how far to bring the wheel well up.

The front wheel alteration was started by putting

the bumper on to get an idea of how far to bring the wheel well up.

The

cut line looks slanted, but it is straight as all alterations are measured

with the body flat on a table and measured along the panel,

it was measured

1' 9" along the top of the panel.

The rear wheel well was much harder to do, as it had to be widened !

The rear wheel well was much harder to do, as it had to be widened !

After

measuring a Polar Lights Slick compared to the original wheel well, we determined

that the Barracuda wheel well will need to be widened 4 scale inches.

4" was left on the middle of the master body, and the front of the

wheel well was cut out.

Then from a spare body, the new section of the wheel well was cut in the

middle of the wheel well,

when installed it will give me 2" on each

side, after the rear section was put on....... we now have a 4" wider

wheel well !

Here's the new wheel well alterations !

Here's the new wheel well alterations !

notice the body is still stock length, we will keep it that way, as the

only one that was stretched was the "Virginian".

The Chrome rings around the wheel wells were also removed,

as none of the funny cars had chrome trim around wheel wells !

( For some reason the Polar Lights body has them ) ?.......Dam that thing

is awful !!!!

Some cars have wheel wells that are "Hogged out"

or have a different shape, or have a flare around it,

with this wheel well,

you'll be able to create any look or shape you desire for any particular

car you want to build !

The Valance was filled in with .040 sheet plastic, the Grill recess' were

filled in with .010 sheet plastic.

The Valance was filled in with .040 sheet plastic, the Grill recess' were

filled in with .010 sheet plastic.

( You will need to cut the Grill recess' out if using the stock grill ).

The grill moldings and nose were re-cut to be more prominent as the kit's was very poor and barfly noticeable.

The rear Valance was also filled with .040 sheet plastic.

The rear Valance was also filled with .040 sheet plastic.

The taillights were carefully filled in with putty and all emblems were

sanded from the trunk panel.

All window chrome trim was carefully cut out, then. 010 plastic sheet was

added to the under side.

All window chrome trim was carefully cut out, then. 010 plastic sheet was

added to the under side.

This will act as the new recessed window trim found

on fiberglass Funny Cars ( to mount the clear Plexiglas to ).

New window recess' are

finished.

New window recess' are

finished.

Also, .020 x .020 Plastic strip was added to the top of the side windows.

Here you can see the window trim on the inside of the body and the smoothed

out puttied areas.

Here you can see the window trim on the inside of the body and the smoothed

out puttied areas.

I had hoped to use the rear window of the PL model, but they did some weird

re-shaping of their rear window,

and I needed to do ours correct. So, you

will need to use .010 or .020 clear plastic for all the windows.

BODY PARTS

We want to give you the option of a Blocked out grill

area, so we started with a stock '68 Grill and filled

it with Ever coat putty.

We want to give you the option of a Blocked out grill

area, so we started with a stock '68 Grill and filled

it with Ever coat putty.

The grills were separated and sanded to match the angles of the original

grill shell.

The grills were separated and sanded to match the angles of the original

grill shell.

This will make it easy for a grill filler.

This will make it easy for a grill filler.

We wanted to give you a separate rear spoiler (as

not all cars ran a spoiler),

We wanted to give you a separate rear spoiler (as

not all cars ran a spoiler),

and after looking at the Polar Lights Cuda,

we decided to make a better one from scratch. So after digging around,

we

started with a '66 Corvair rear trunk (with spoiler), cut it off the trunk

lid, and re-shaped it to fit our new Barracuda trunk.

How's this for a perfect fit !

How's this for a perfect fit !

This new spoiler has a better angle and looks more correct to what the real

cars were running.

Master Model is finished

Compare

our Speed City Body (on the right) to the Polar Lights body

They look like two completely different bodies,

ours being "correct" of course !

This is the first '67-'68 Barracuda Funny Car in model

history !

Finally, we can all build a correct '67-'68 Barracuda F/C.

And with all the extra Front & Rear body parts, there is more than 30

ways to build this Funny Car body !

Resin

kit will include:

* Correct 1968 Barracuda Funny Car Body

* Two separate style Front Spoiler's...... ( not all

cars ran a spoiler )

* Separate Rear Air Foil..... ( not all cars ran a rear air foil )

* Stock '68 Grills..... ( with block out headlights )

* Angled Grill Blockouts...... ( some cars had blocked out grill areas )

* Separate Bumpers...... ( as some cars didn't run with bumpers )

A Polar Lights Barracuda or Charger F/C will be needed for a donor kit !

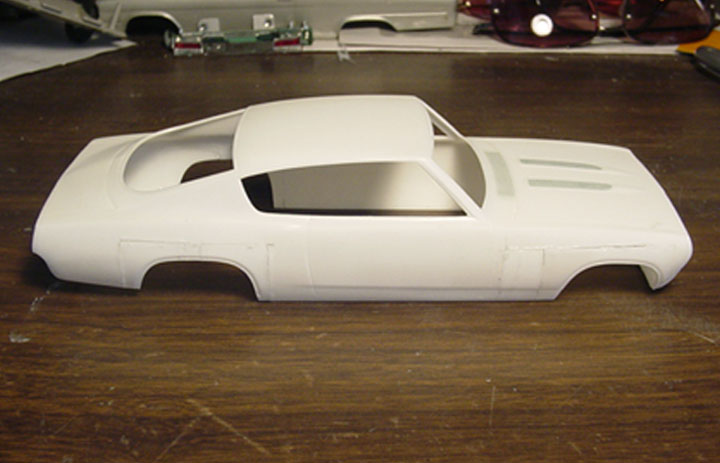

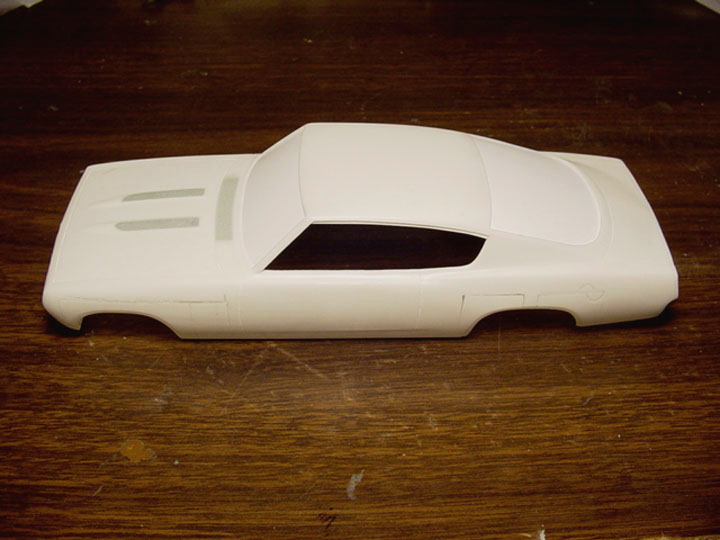

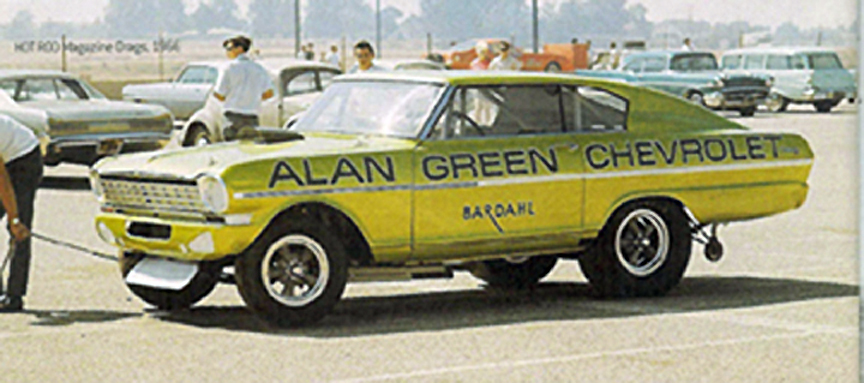

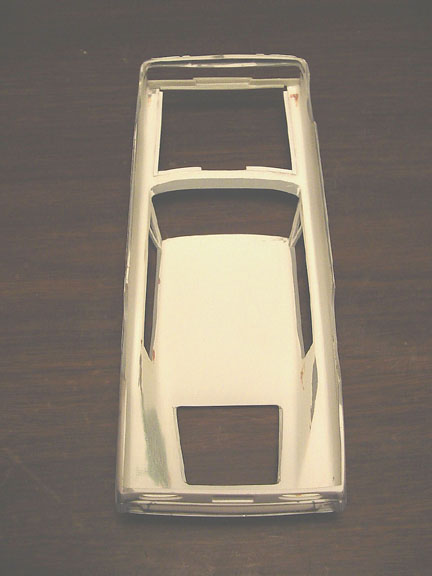

1963/'65 CHEVY NOVA FASTBACK

Were

going back to the original Master Model and re-designing it to be more accurate

and to include an A/FX Chassis !

The inside of the original

body was too thick,

The inside of the original

body was too thick,

so it was "SUPER THINNED" and now its as thin

as a Plastic kit model !

The body was completely sanded smooth to remove any imperfections !

The body was completely sanded smooth to remove any imperfections !

The original hood supports fit very poorly because we didn't have the hood from

the original model ( that's another long story ),

The original hood supports fit very poorly because we didn't have the hood from

the original model ( that's another long story ),

so we added all new correct

hood supports.

The Block-outs from the bumper holes in the front splash pan were added, to

more accurately resemble the "Alan Green Chevrolet" car.

Also, a radiator

/ fender support was added for strength & appearance.

The rear window was opened up correctly and bumper mount holes were added to the

rear valance,

The rear window was opened up correctly and bumper mount holes were added to the

rear valance,

and a licence plate recessed area was put in (as photo of real

car shows)

The Alan Green car has a parachute surround on the trunk deck ,

so we will add that as a separate item !

CHASSIS

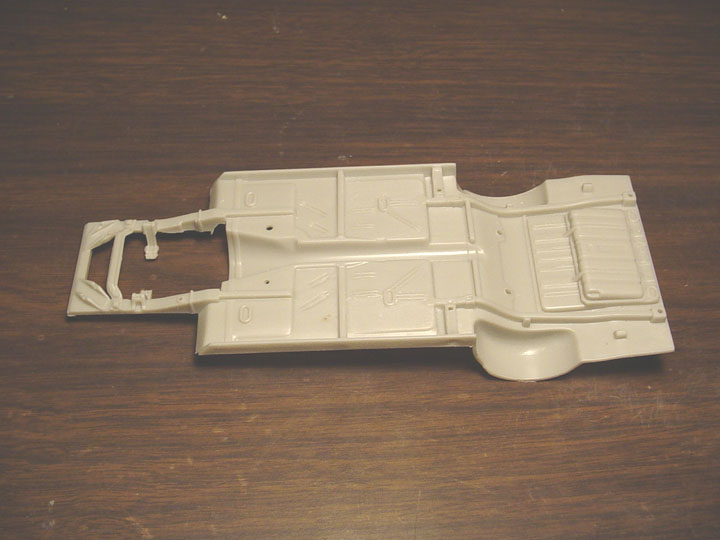

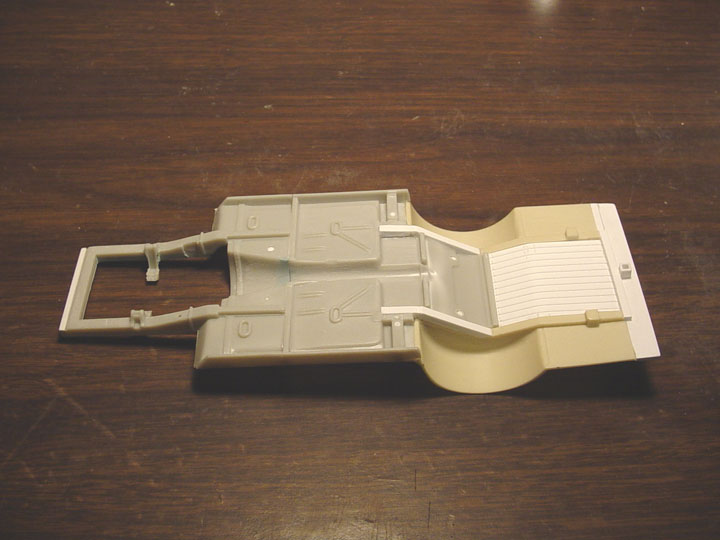

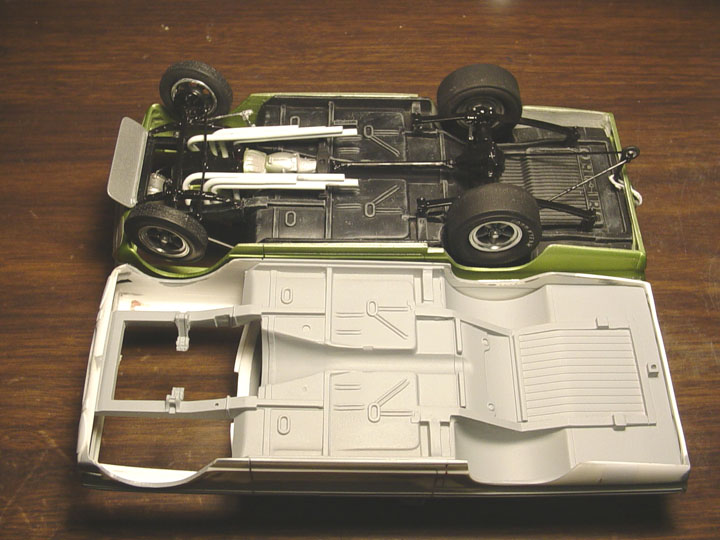

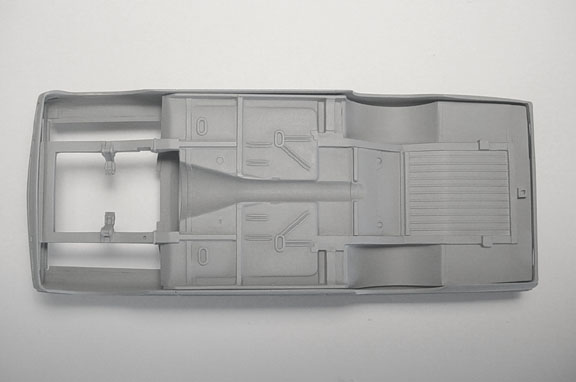

We'll be adding an Altered Wheelbase Chassis to this kit. Starting with an amt.

'66 Chevy Nova SS,

We'll be adding an Altered Wheelbase Chassis to this kit. Starting with an amt.

'66 Chevy Nova SS,

( you'll need that kit to use as a donor for Interior, Motor

& Chassis parts. Photo shown is a stock '66 Nova Chassis (not altered yet).

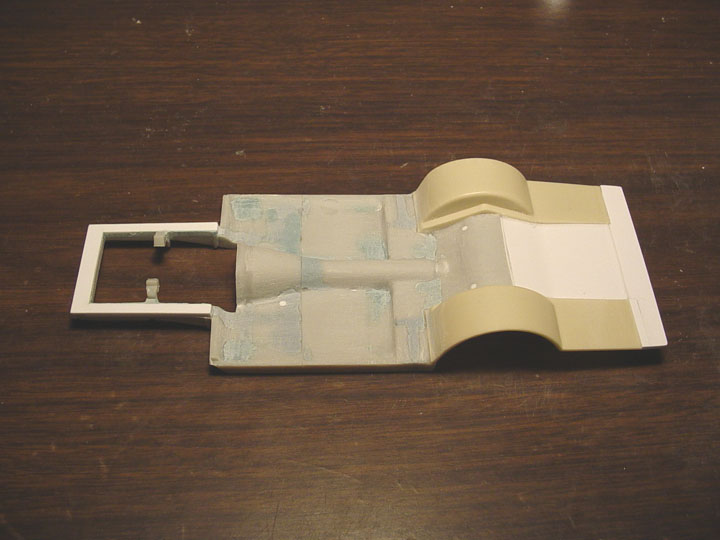

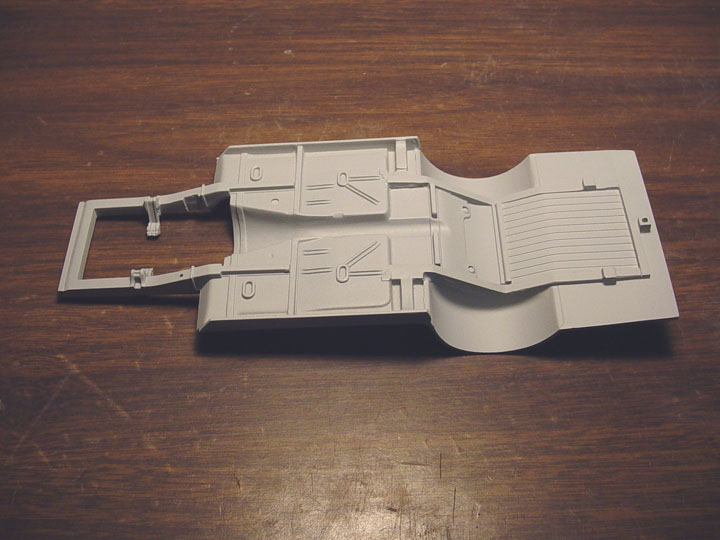

15 scale inches were removed from the mid-section of the floor pan.

15 scale inches were removed from the mid-section of the floor pan.

The wheel

wells were borrowed from our Square Tube Chassis, and installed at the same

place as the original wheel wells.

Extra frame rails were added to the Chassis

using plastic strips.

The gas tank and trunk floor was removed and a new trunk floor pan was installed

using some Plastruct ribbed sheet.

The original suspension mounts on the frame

was removed and plastic strips were added to the front frame rails.

All holes

were filled with plastic round tube. As a bonus were adding the wheelie bar

mount !

Here is the finished Chevy Nova Fastback A/FX Chassis.

Here is the finished Chevy Nova Fastback A/FX Chassis.

Were not adding the Firewall, Interior floor or the door panels, as they will

be in the donor kit anyway along with other parts.

(

you will need to use an amt. '66 Chevy Nova SS, as a donor ).

As you can see, it's a perfect fit !

As you can see, it's a perfect fit !

This new chassis is what I should have done to my original build, and as you

can see,

I cheated I my model and sanded down the frame rails & inner wheel wells,

so I could get the slicks to fit.

This new Chassis is much more accurate as

has room for even bigger slicks, if you choose to use them ?

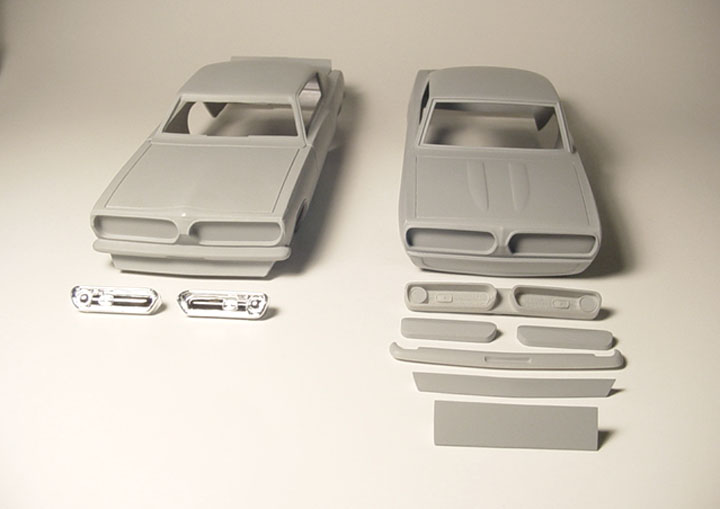

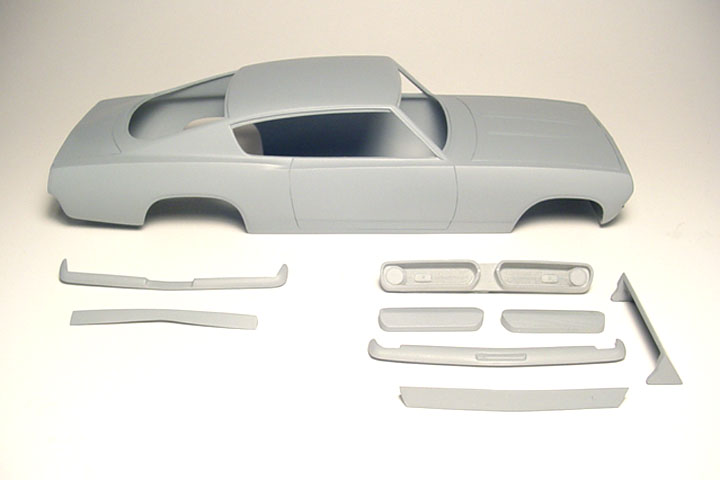

'63

& '65 NOVA GRILLS

To set the record straight:

There was never a '64 or '65 Chevy II Nova Fastback.

ALSO: Chevrolet never built a "Fastback"

version and it was never a production model.

The original '63 Chevy II Nova Fastback's were built

by Bill Thomas.

Bill built a few of these cars to be used for the NASCAR and the Drag Racing

Circuit.

Later, some of these cars ran with '65 Nova Front fenders & Grill, but kept

the '63 Body.

This is the reason behind us creating a separate '63 & '65 Grill !

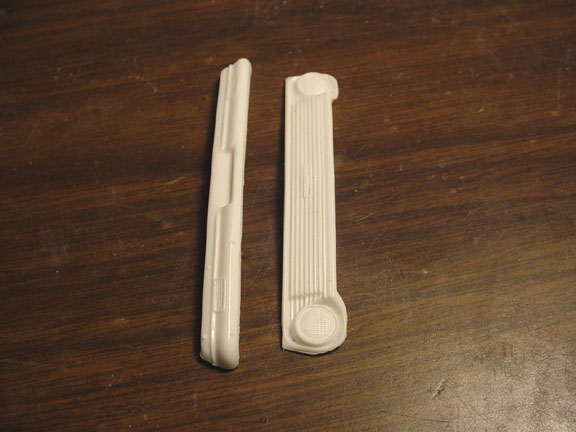

After finding an original amt '63 Nova grill, the grill & bumper were separated.

After finding an original amt '63 Nova grill, the grill & bumper were separated.

Using a '65 Nova grill/bumper from the Chevy II Funny car, the grill & bumper

were also separated.

Using a '65 Nova grill/bumper from the Chevy II Funny car, the grill & bumper

were also separated.

Here's the new '63 & '65 Grills, in the progress of adding block out headlight

covers.

Here's the new '63 & '65 Grills, in the progress of adding block out headlight

covers.

Also: the '65 Nova bumper has been modified with longer sides and bumper mounts.

The side marker light holes in the body, will have to

be filled if using the '65 Grill !

We went back to the front valance, to make it fit the new grills by adding plastic

strips, and cutting

We went back to the front valance, to make it fit the new grills by adding plastic

strips, and cutting

correct holes to recreate the original valance.

.010 sheet plastic will be added to the back of the valance later.

PARACHUTE

WITH SURROUND

After being asked

several times about how to build the Parachute & Surround for the Alan Green

Car,

it was decided we had to make one !

Starting with an old

mpc parachute, I made a mold and cast a few up, then the sides were sanded down to

Starting with an old

mpc parachute, I made a mold and cast a few up, then the sides were sanded down to

make it smaller. We added .030 x .100 plastic strip all around the parachute

for a surround.

Here's the new Parachute with Surround

( this will be a separate item, NOT molded to the body ) .

Here's the new Parachute with Surround

( this will be a separate item, NOT molded to the body ) .

We also felt it unnecessary to cast the taillights separately because they were

so small, and it would be easier to just foil them while on the body.

MASTER MODEL IS FINISHED !

............................................................................................................................

'63 Grill .............. '65 Grill& Bumper

Model

is now Available !

Page 4

All rights reserved. Do not copy any Speed City Resin bodies or parts without permission and consent.