WHEN YOU DEMAND HIGH QUALITY AND ACCURACY, GO WITH........ SPEED CITY !

"IN PROGRESS"

PAGE 4

On these pages you'll see how we create our master models,

so you can see the labor of love that goes into all our products.

Follow along

as we create a NEW  ....

....

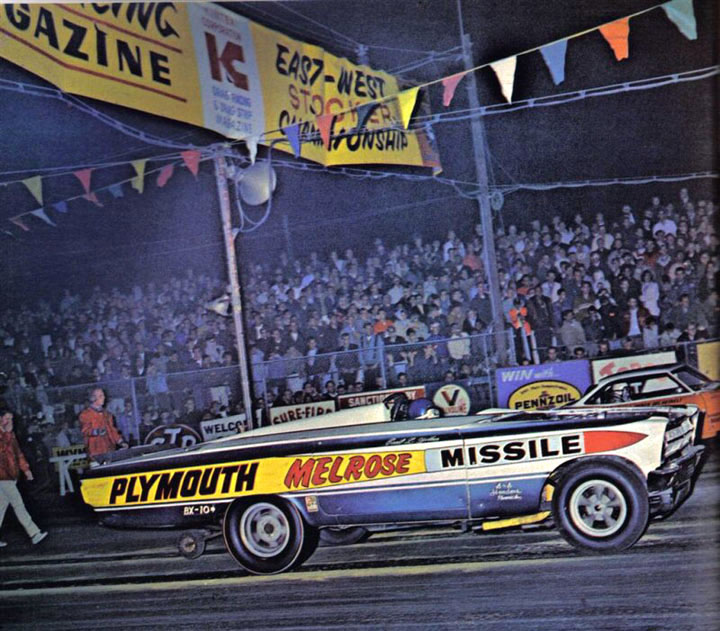

TOPLESS "MELROSE MISSILE" A/FX

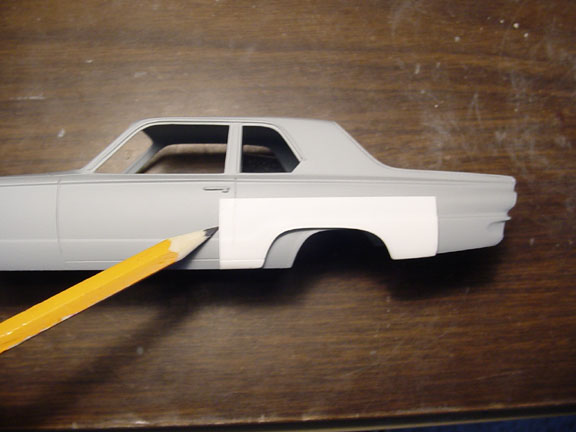

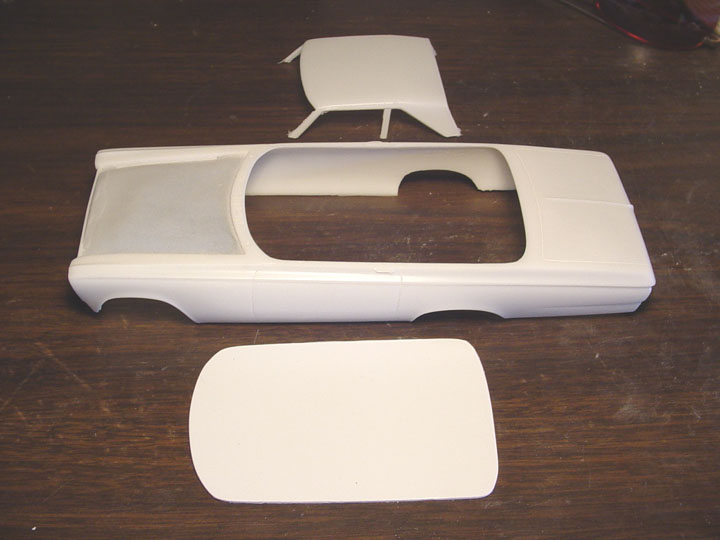

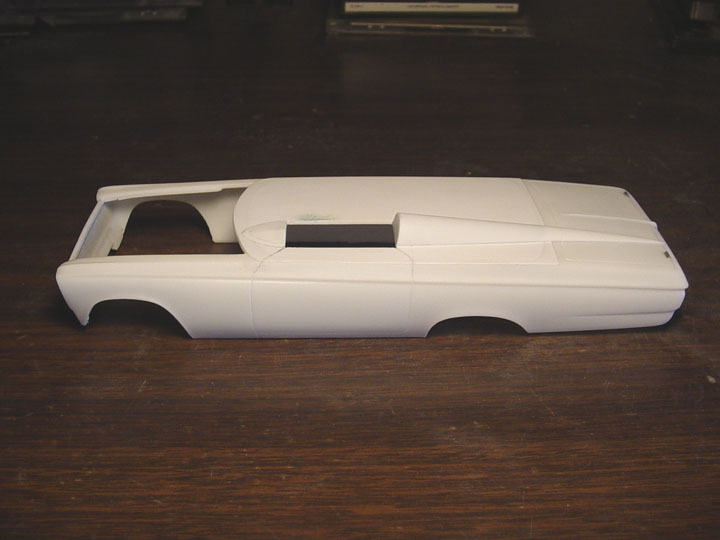

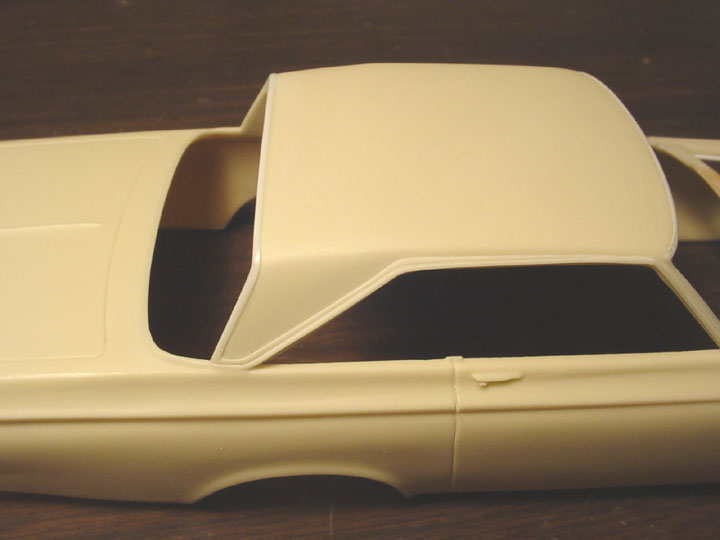

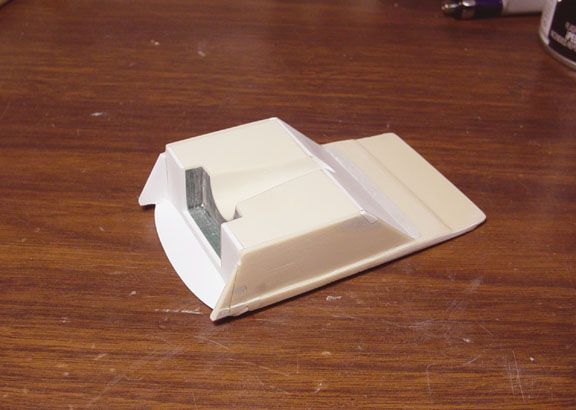

Starting with our '65 Ply

Belvedere A/FX resin body, the Hardtop roof was removed and a filler panel was

cut from 0.30 Plastic sheet,

Starting with our '65 Ply

Belvedere A/FX resin body, the Hardtop roof was removed and a filler panel was

cut from 0.30 Plastic sheet,

and was given' a slight arch to match the top of

the body.

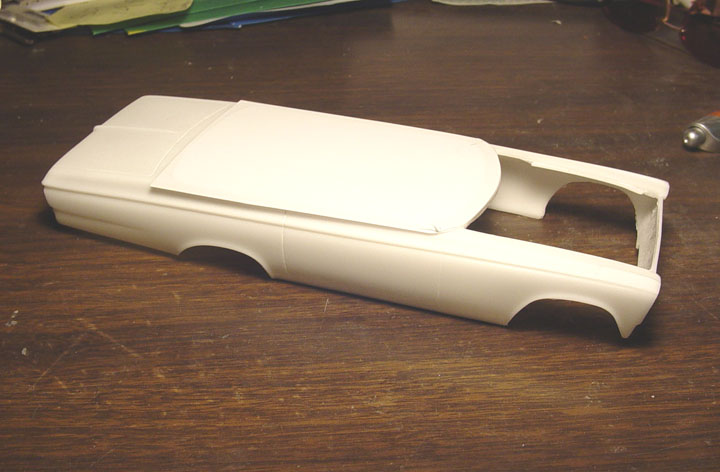

To make the tonnue cover look like sheet metal, 0.10 plastic sheet was cut and

formed to the top of the body.

To make the tonnue cover look like sheet metal, 0.10 plastic sheet was cut and

formed to the top of the body.

Just need to clean it up now !

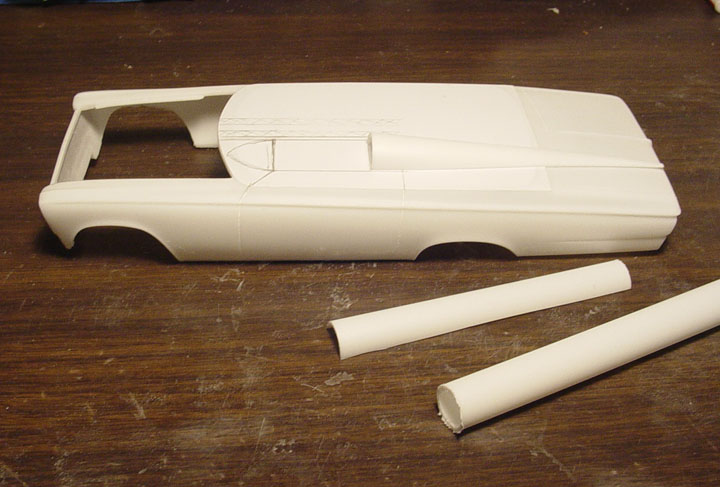

Evergreen plastic 1/2" TUBE was used for the Canopy, the tube was cut in

half, and then shaped on an angle and sloped down, to create the point.

Evergreen plastic 1/2" TUBE was used for the Canopy, the tube was cut in

half, and then shaped on an angle and sloped down, to create the point.

You

can see the pencil tracings where the blue racing stripes would be located.

This was done to insure a correct location for the canopy and hole for driver.

Now its starting to look like the" MELROSE MISSILE". You can also see the tracing for the bullet shaped cowl.......

soon to come.

The interior tub & chassis was installed to measure were the dash would

line up with the new cowl.

The interior tub & chassis was installed to measure were the dash would

line up with the new cowl.

The headrest was filled in with sheet plastic, the

hole for the driver was cut out and New door lines were scribed in.

The Canopy was hollowed out from the bottom for realism and to save on weight

and resin.

The Canopy was hollowed out from the bottom for realism and to save on weight

and resin.

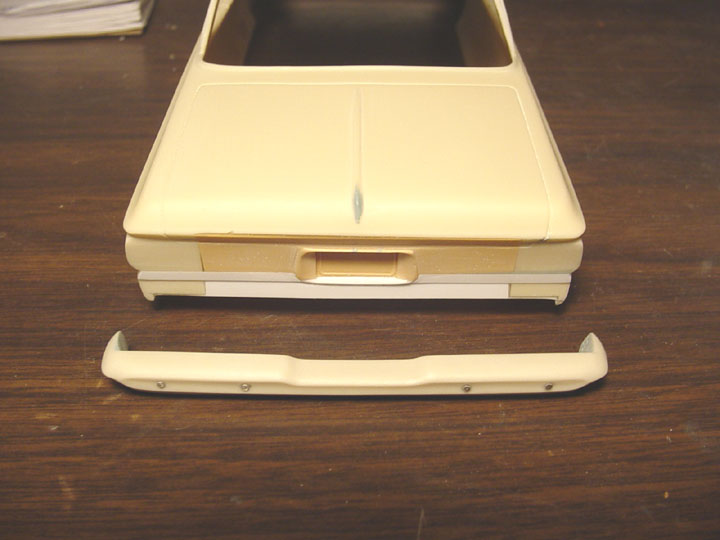

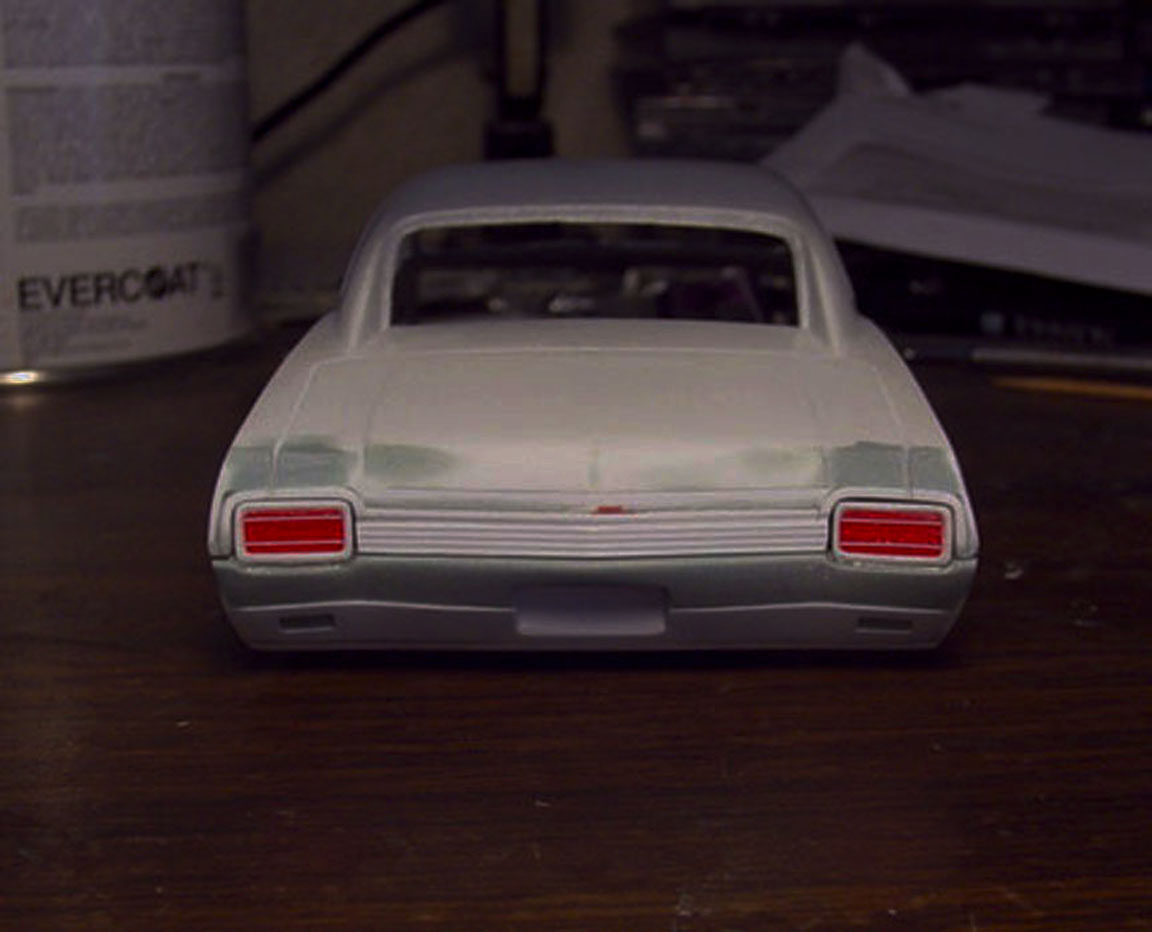

The rear valance was slightly rolled, and rear 1/4 panels were slightly re-shaped.

The rear valance was slightly rolled, and rear 1/4 panels were slightly re-shaped.

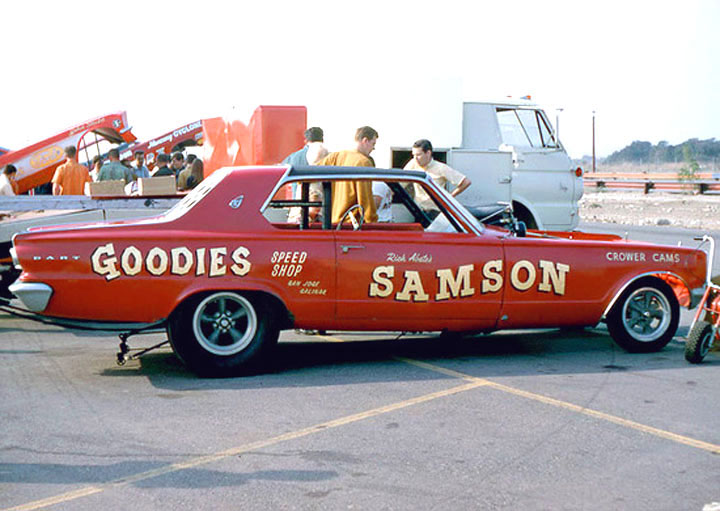

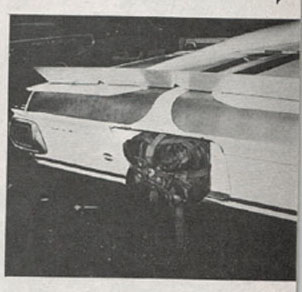

My initial plan was to include the rear "AIR FOIL" but, after finding

this rare photo (below),

it would have been to hard to do the paint job with

the Air Foil on it.....So instead,

I added hinges to be able to mount an aluminum

sheet rear foil to the new hinges on a 45 degree angle.

At this point the master is finished, other than priming & polishing !

At this point the master is finished, other than priming & polishing !

MASTER

MODEL IS FINISHED !

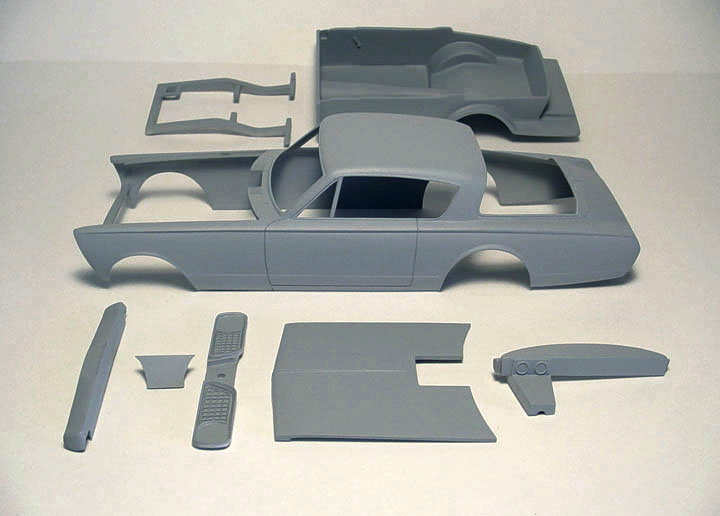

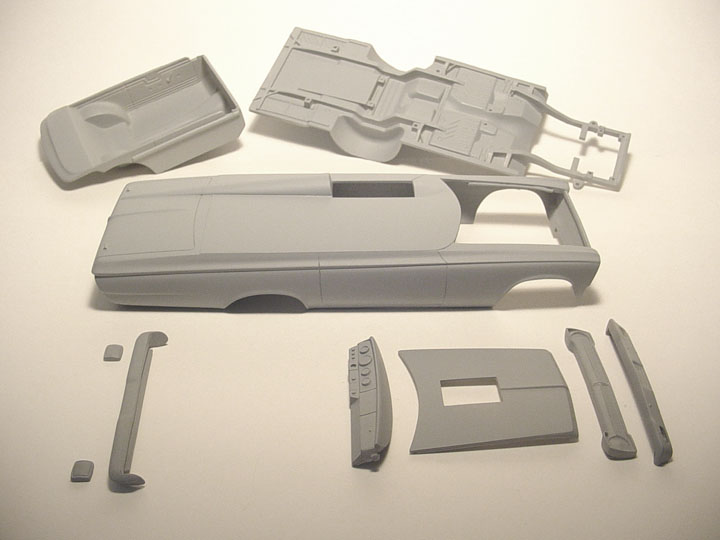

This model will come with the same parts as the '65 Plymouth

Belvedere & Sedan A/FX.

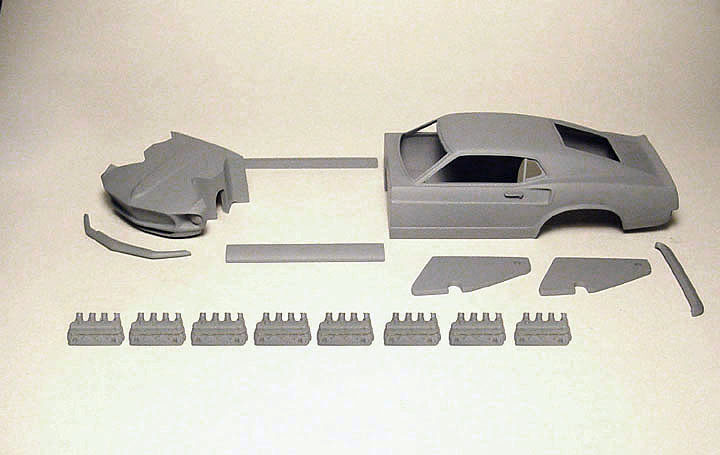

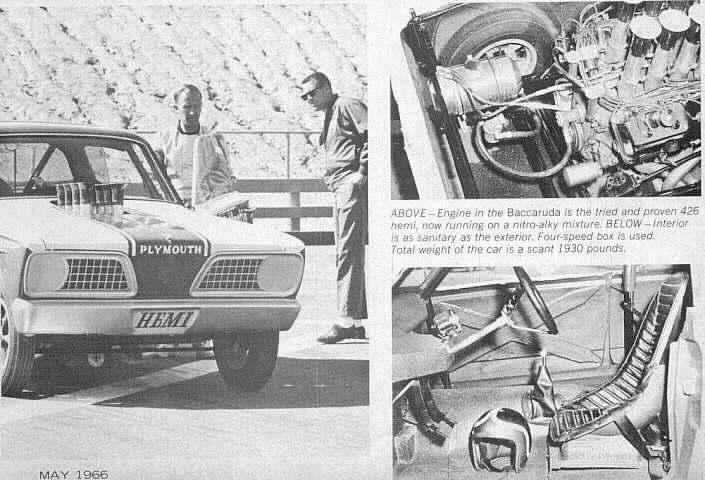

'66

LONG NOSE BARRACUDA FUNNY CAR

Mastered by: Ron Ramsey and Scott Kapellusch

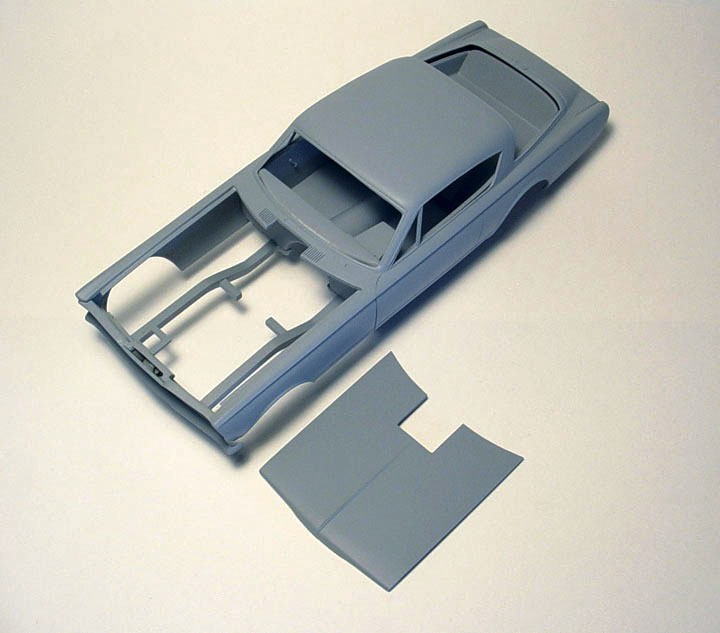

Ron

has passed the master over to us to rework some issues, such as:

Chassis / Interior tub, Dash, Front frame clip &

extra body modifications.

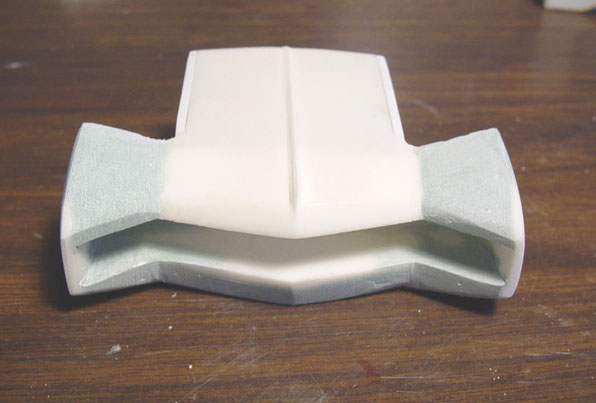

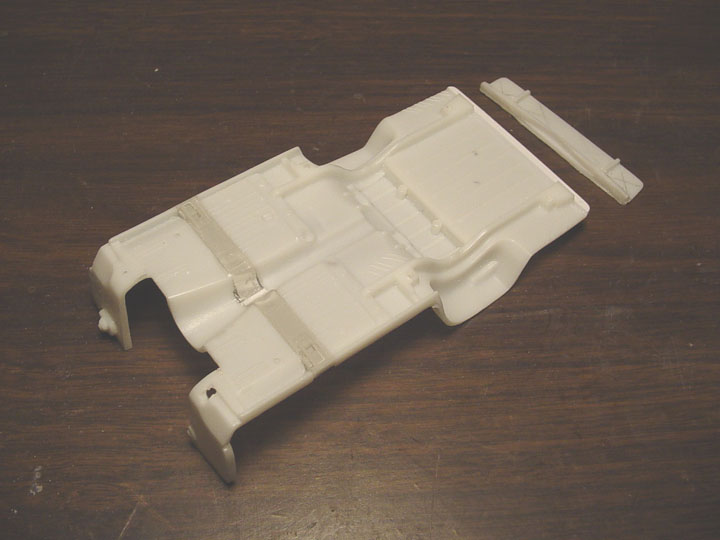

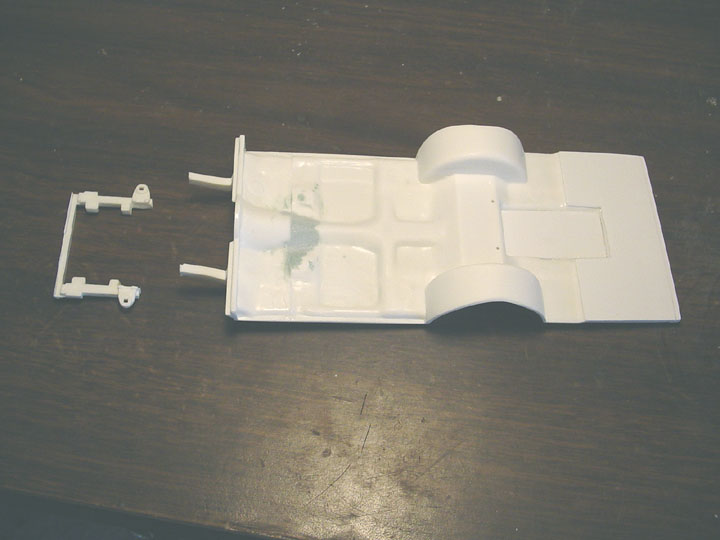

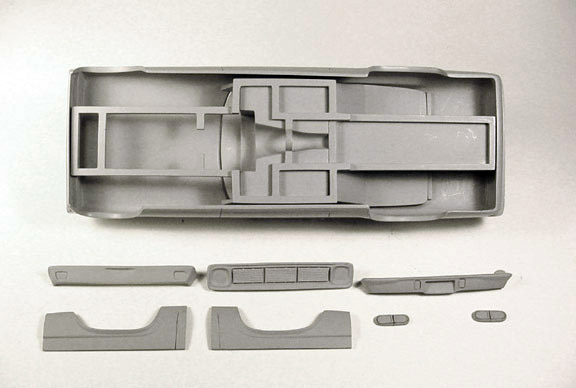

Ron Ramsey

started this Interior tub by using the center of our Speed City Long Nose

Mustang F/C Interior tub.

Ron Ramsey

started this Interior tub by using the center of our Speed City Long Nose

Mustang F/C Interior tub.

Ron added some width to all the sides of the Chassis floor

with sheet plastic, then added his own door panels,

by copying a stock '66 Barracuda

interior tub.

AMT Funny Car Wheel wells were installed as well as a new firewall & Trunk shield.

He left the clean up to me (Scott Kapellusch).

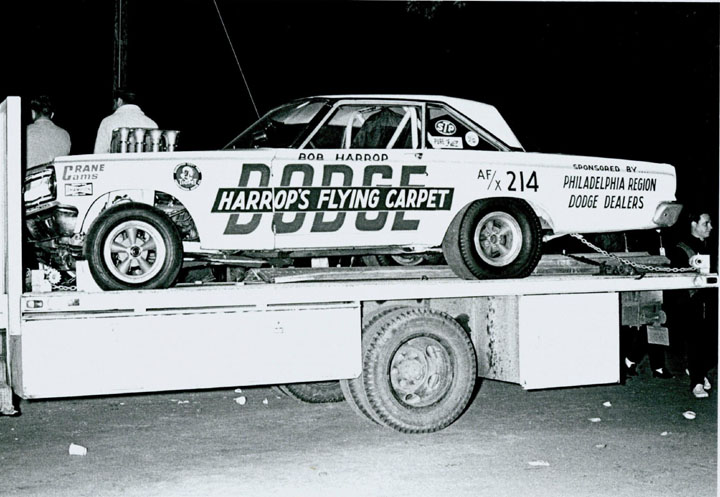

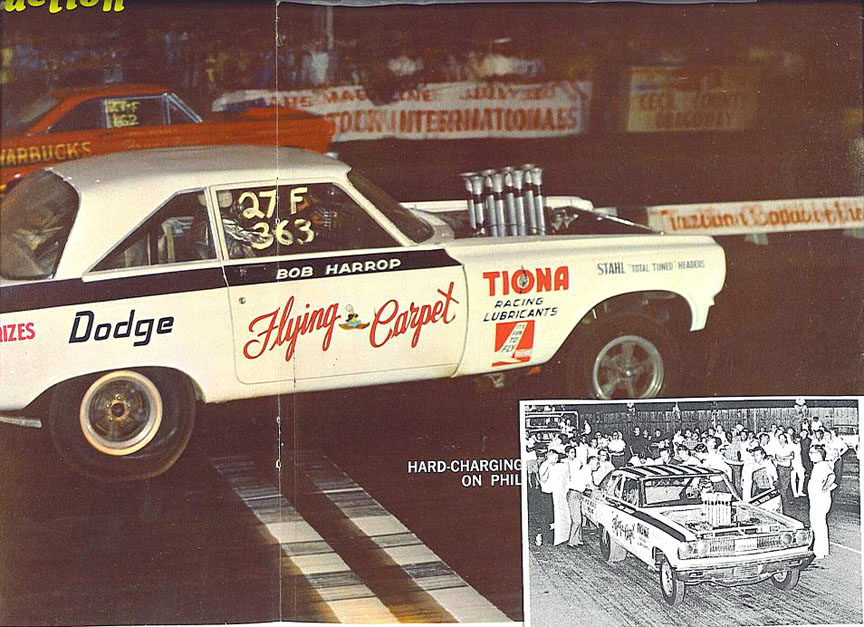

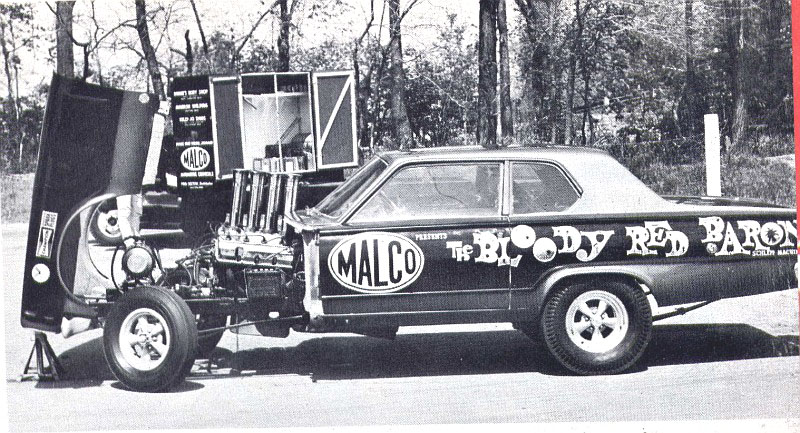

Using these photos as reference....

Using these photos as reference....

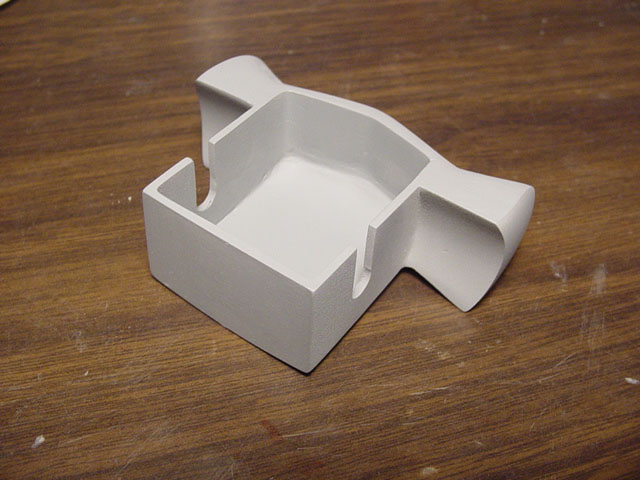

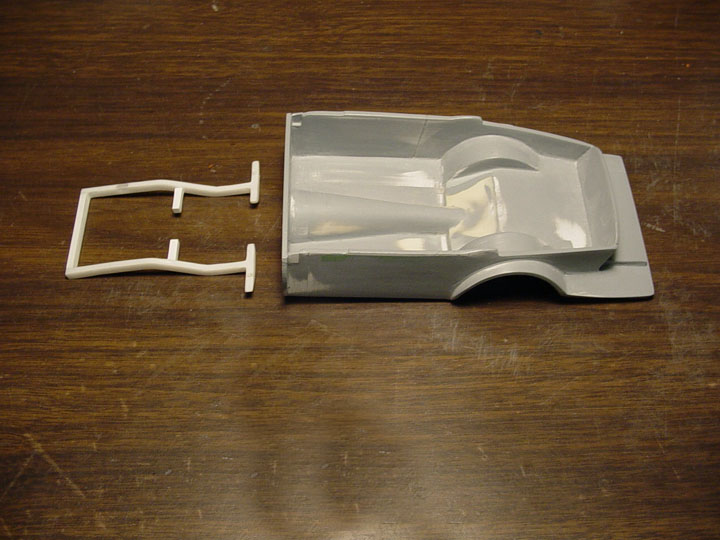

I installed new frame rails

to the chassis to be in alignment with the Frame Clip from our '65 Gene Snow Rambunctious

Dart.

I installed new frame rails

to the chassis to be in alignment with the Frame Clip from our '65 Gene Snow Rambunctious

Dart.

Motor mounts were also added. Fuel tank mounts will also be

added later (not shown in this photo).

I created a Steering Column Box (re-worked from our '66 Corvair Funny Car), to match the the Sox & Martin Cuda.

The Dash was reworked from

the AMT Hemi Under Glass kit.

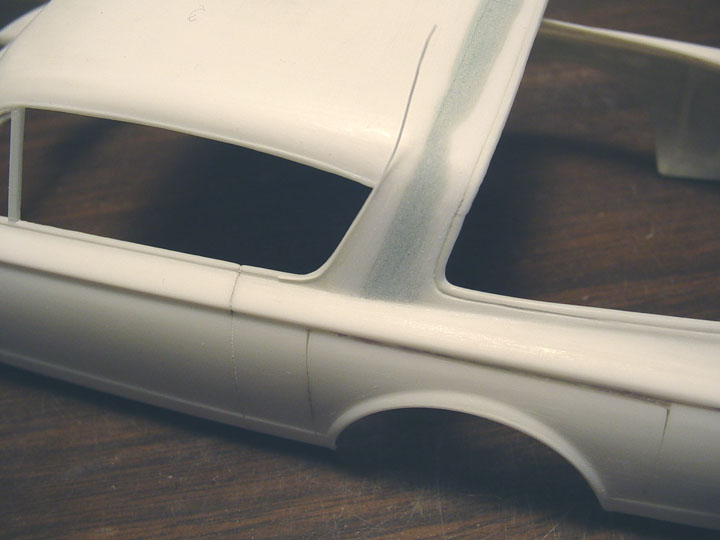

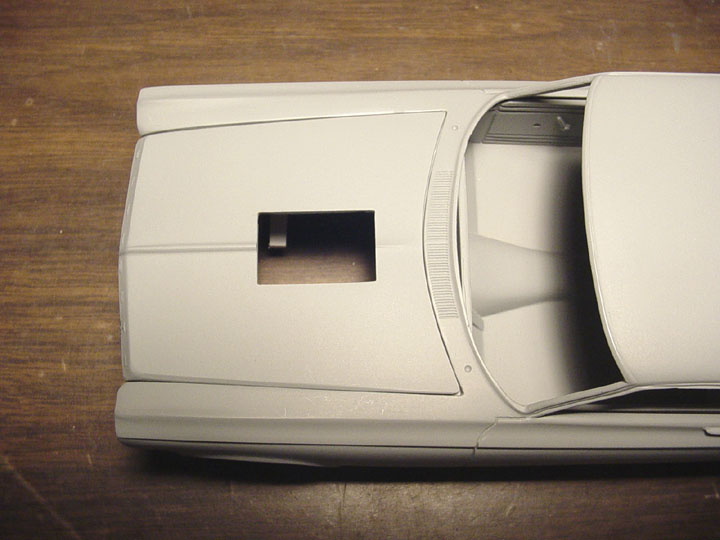

After doing some research

I realized that the AMT kit got the sail panel on the roof wrong !!!

After doing some research

I realized that the AMT kit got the sail panel on the roof wrong !!!

Here is a stock 1966 barracuda, notice there is no step in the roof Sail panel,

but is angled downward.

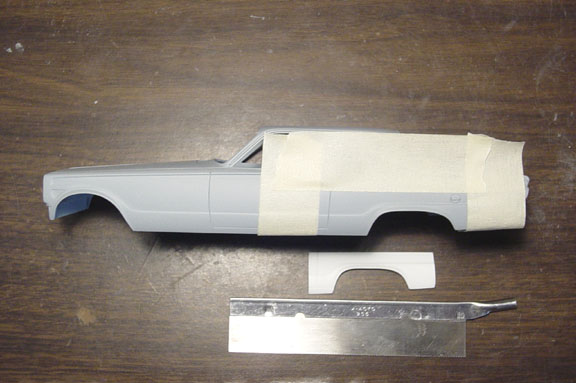

I had to strip off Ron's primer coat, so the putty will bond stronger. Tape was used to mask off the area to be puttied.

I had to strip off Ron's primer coat, so the putty will bond stronger. Tape was used to mask off the area to be puttied.

The top of the roof slanted down too much, so that was also puttied to make

a perfect transition.

The top of the roof slanted down too much, so that was also puttied to make

a perfect transition.

Now its just perfecting the angle from top to rear.

The original amt kit drip rails were too faint and could barely make it out,

The original amt kit drip rails were too faint and could barely make it out,

so plastic strip was used to create a new ones !

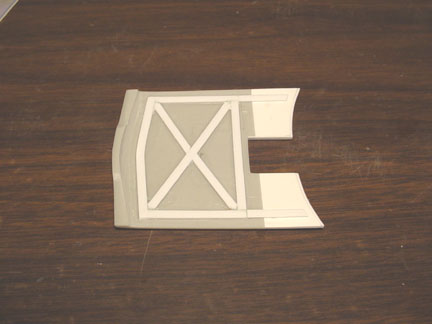

The grill was designed to match the Sox & Martin Cuda (which is what most

of us will build).

The grill was designed to match the Sox & Martin Cuda (which is what most

of us will build).

Some of the

other cars were actually the old Sox & Martin Barracuda anyway, so this only made sense to do!

Hood supports were added

for strength and appearance !

Hood supports were added

for strength and appearance !

THE MASTER IS FINISHED !

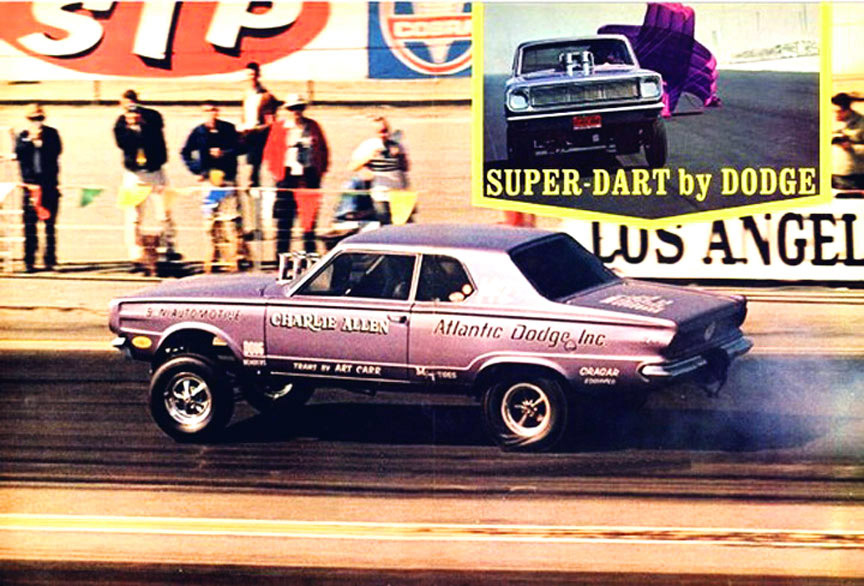

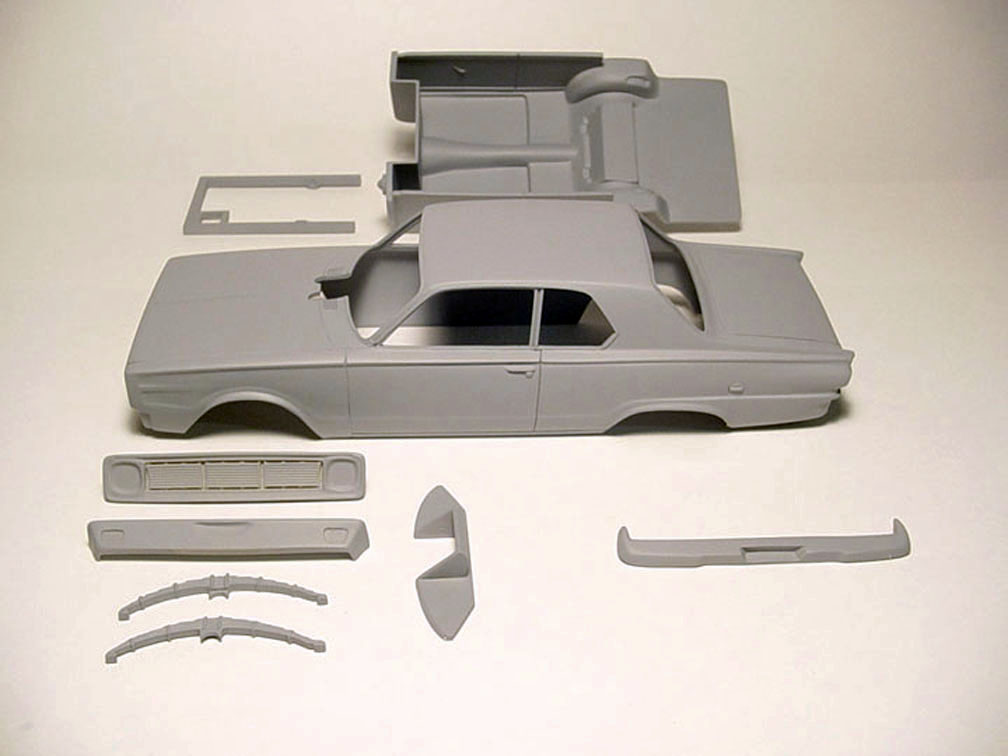

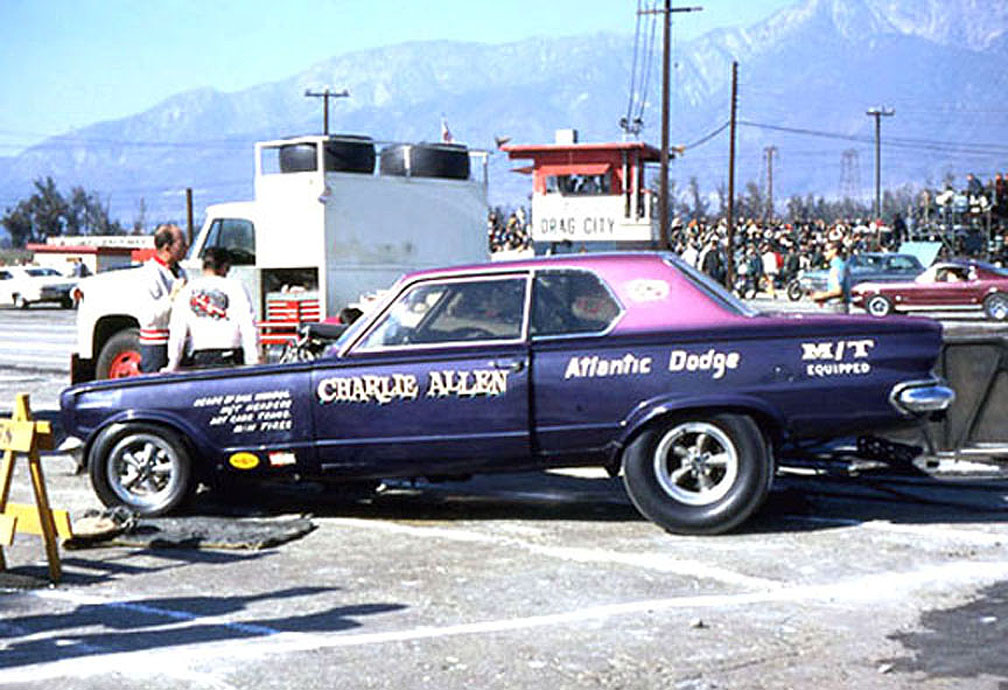

Charlie

Allen's

"PURPLE TERROR"

1965/'66

Dodge Dart A/FX

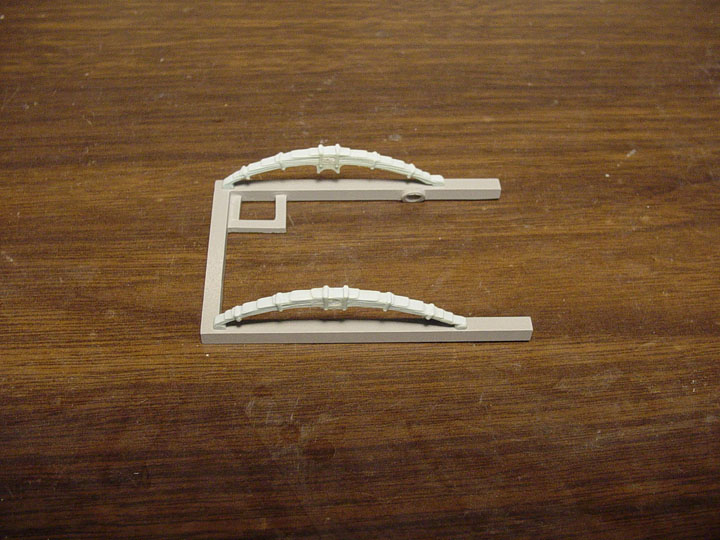

THIS

ITEM HAS BEEN RE-MASTERED WITH

NEW AWB CHASSIS / INTERIOR TUB,

SQUARE TUBE FRONT FRAME, LEAF SPRINGS

& DOOR PANELS.

There

were things we couldn't do to the original Charlie Allen Dart,

because of all

the other models we wanted to build from it.

But since this will be an all new

tool,

we want to create an all out correct body..... Such

as: Hogging out the front of both front & rear wheel wells,

cutting a hole

in the cowl & hood for the injector stacks and scribing a new straight door

line for the flip front end.

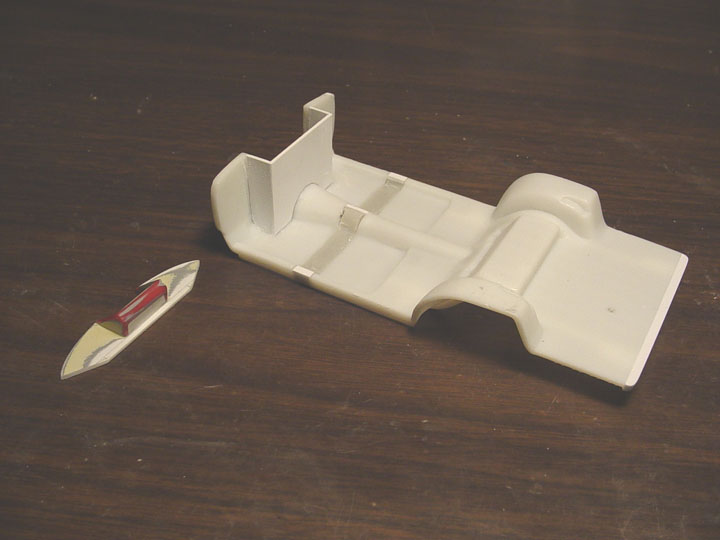

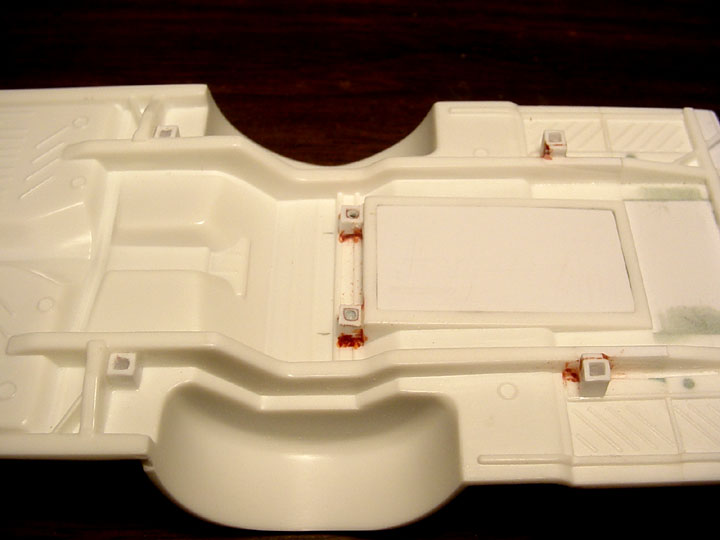

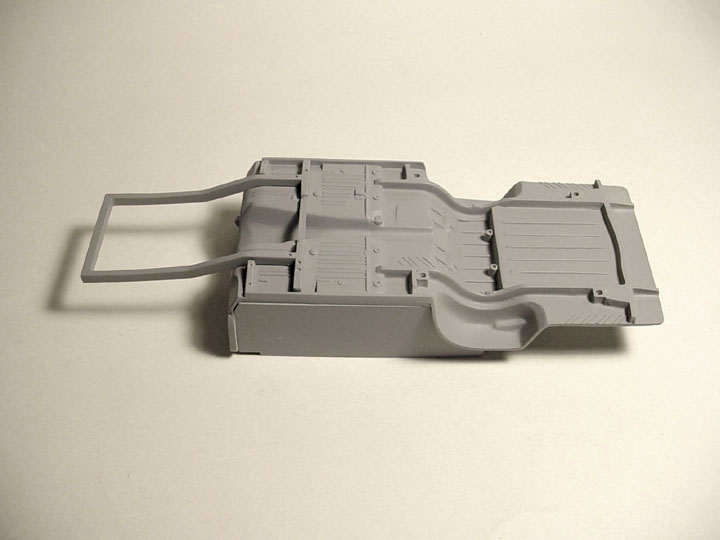

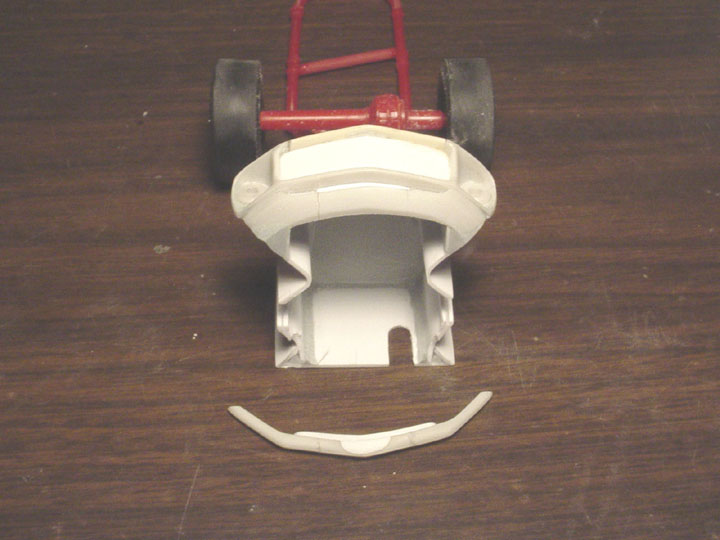

Using the new chassis from

our '65 Dart AFX, we needed to bring back the rear of the chassis

Using the new chassis from

our '65 Dart AFX, we needed to bring back the rear of the chassis

(to stock

wheel base position), and lengthen the front of the chassis.

The tail piece

was removed and we added a new section of interior/ chassis floor.

The

'65 Dart chassis was stretched by using a'71 Ply Duster 340.

The area for

the new motor surround has been cut out in this photo.

Here is the new fire wall with motor surround, and the updated Dash Cowl

Here is the new fire wall with motor surround, and the updated Dash Cowl

(with

scoop).

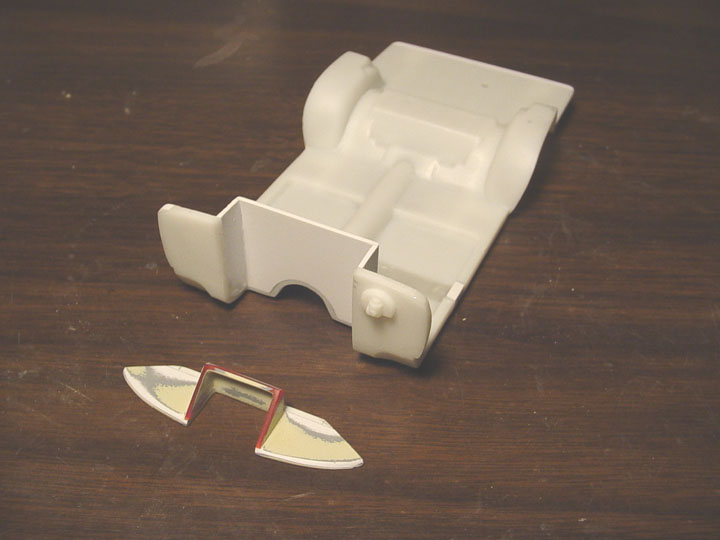

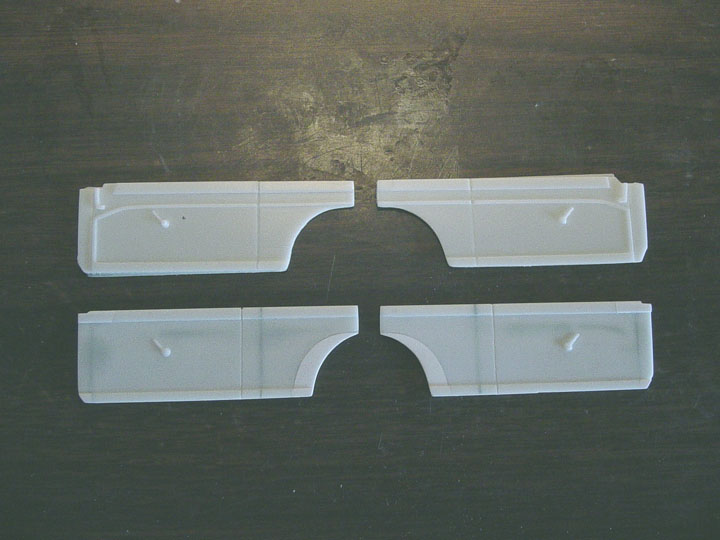

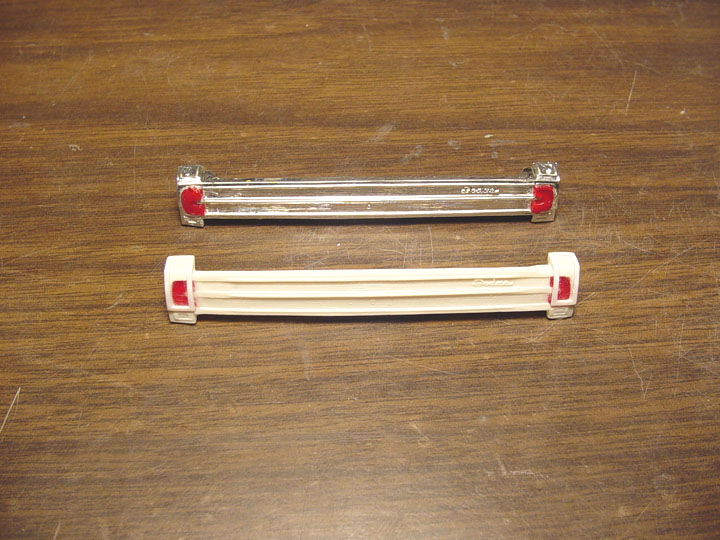

Starting with the '65 Dart AFX door panels (shown on top), the chrome trim was

removed,

Starting with the '65 Dart AFX door panels (shown on top), the chrome trim was

removed,

the wheel well area had to be lengthened, as well as some minor trim

inserts.

Old door lines were filled in and new door lines had to be scribed.

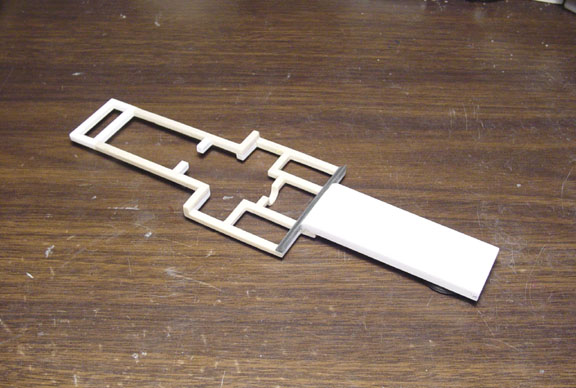

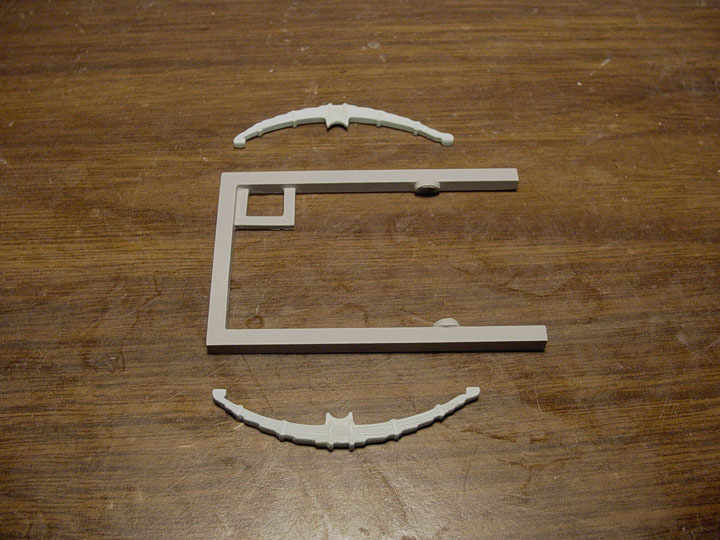

This Square tube frame was

designed from the original frame I built for my personal build up.

Were also adding

a set of "Malco Willys Gasser" Rear leaf springs, to use as the front

leaf springs on the new frame.

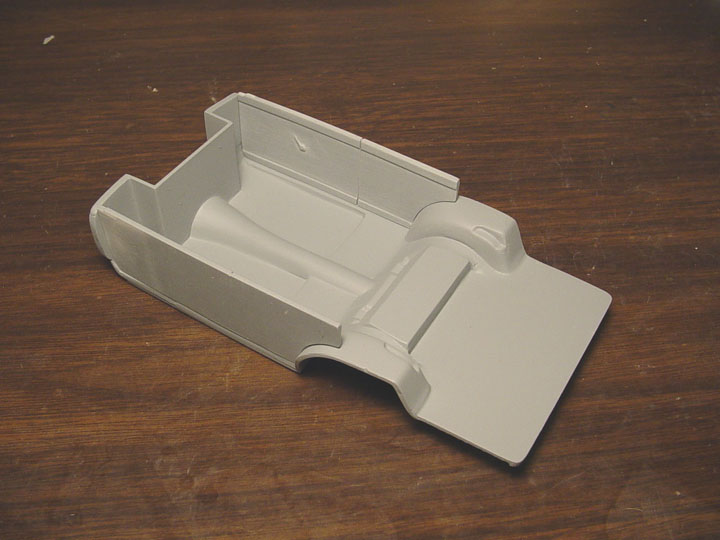

Here is the new Interior tub

!

Here is the new Interior tub

!

Here is the new chassis with square tube frame (with motor mount location pins) and Front leaf springs.

Here is the new chassis with square tube frame (with motor mount location pins) and Front leaf springs.

The new Charlie Allen "PURPLE

TERROR" body....... Now with correct body modifications

!

The new Charlie Allen "PURPLE

TERROR" body....... Now with correct body modifications

!

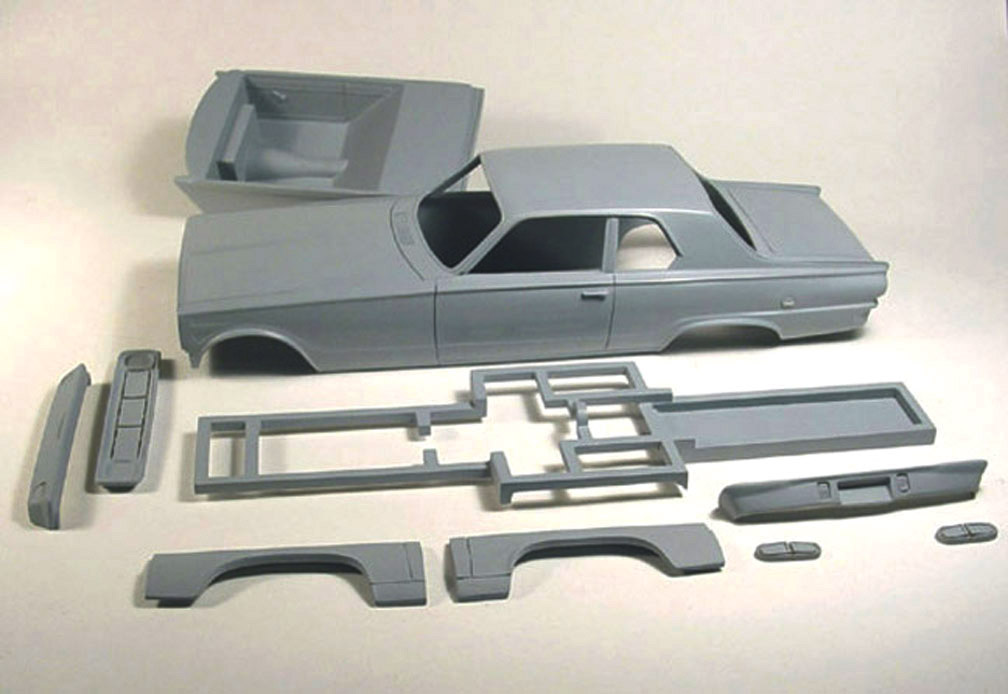

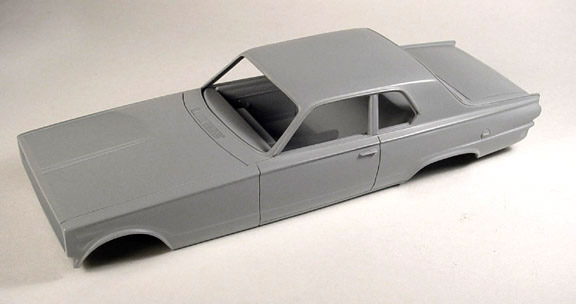

1965 Dodge Coronet Hardtop A/FX

Our goal is to create an all out "Correct" '65 Dodge Coronet A/FXer.

We decided NOT to

use the Polar Lights Coronet because of all the bad reviews it received.

I personally never bothered buying one, hearing it was too toy looking and out

of proportion.

Our 1965 Dodge Coronet A/FX will be designed from 2 original amt. bodies !

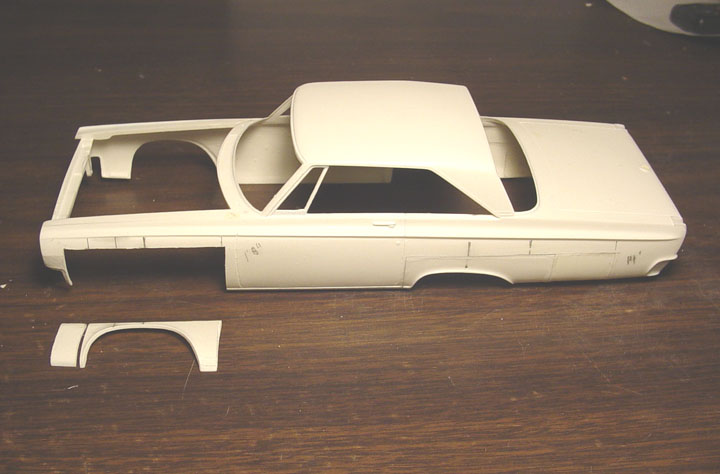

The

entire stock Coronet body was cleaned up of all original defects,

The

entire stock Coronet body was cleaned up of all original defects,

(such as sink

holes, Parting lines, A-Pillar problems,Mounting Pins, Etc.)

Then all the trim,

moldings & emblems were removed, except the 500 trunk emblem and Rocker

Panel Trim.

That was left for alignment for the wheel well alterations.

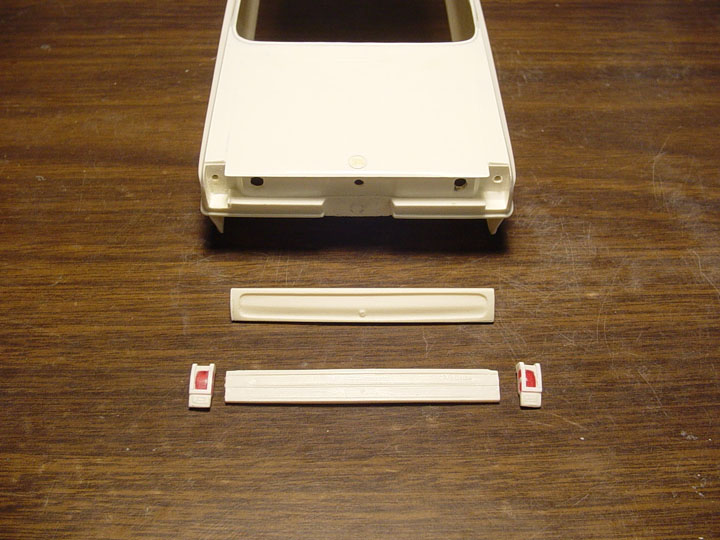

TAIL LIGHTS & MOLDING

The tail lights have been corrected.

The tail lights have been corrected.

We're also adding

a corrected stock trunk molding. It just needs to be fine tuned at this point

!

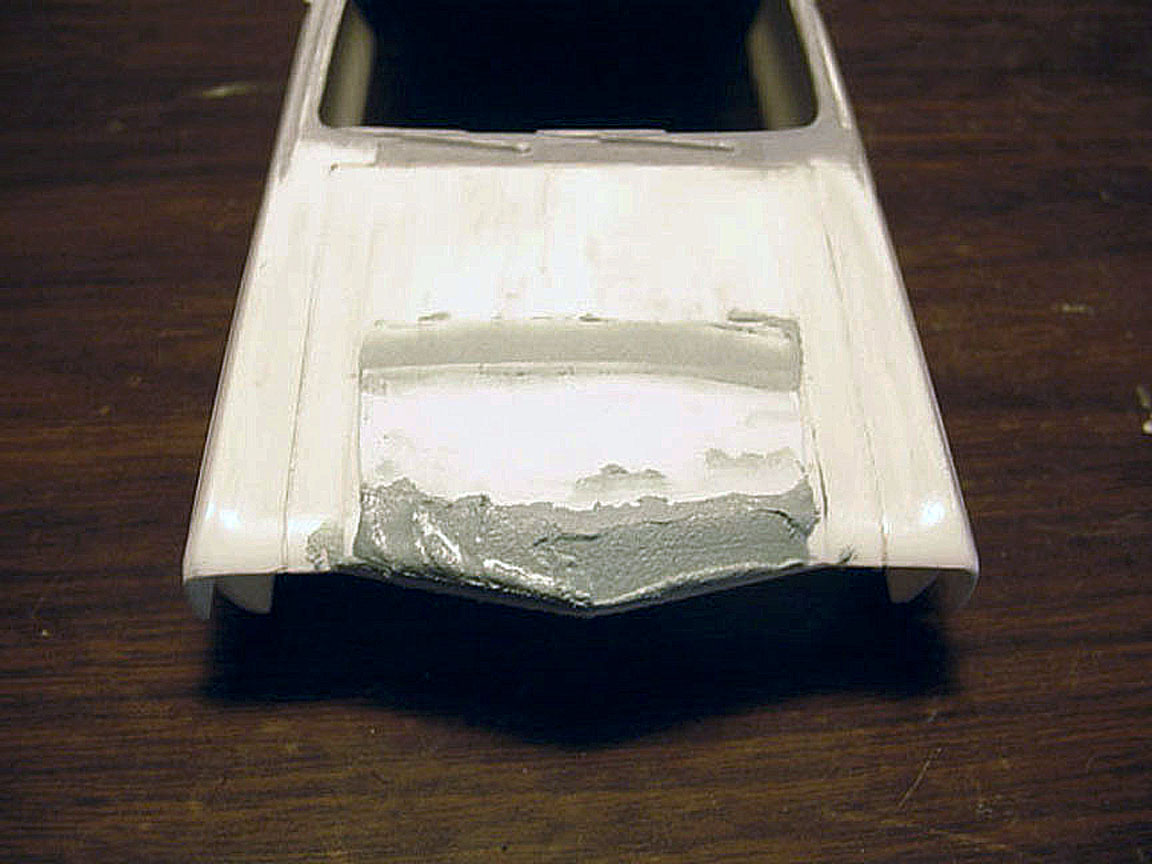

HOOD

The original amt. hood had a Blower hole that was in-correct, so after measuring

it to fit Fuel Injectors,

The original amt. hood had a Blower hole that was in-correct, so after measuring

it to fit Fuel Injectors,

the sides were filled in with sheet plastic.

WHEEL WELL ALTERATIONS

Rear Wheel wells were "correctly"

measured and taped off, using A/FX factory specs.

Rear Wheel wells were "correctly"

measured and taped off, using A/FX factory specs.

you can see the Patch Panel we used

from the other '65 Coronet amt body in the back ground.

you can see the Patch Panel we used

from the other '65 Coronet amt body in the back ground.

Front Wheel wells were "CORRECTLY" measured and taped off.

Front Wheel wells were "CORRECTLY" measured and taped off.

We now have a totally correct

wheel base (Front & Rear).

We now have a totally correct

wheel base (Front & Rear).

Adding a bead

of super glue to all the joints, we now come to the hard part, sanding it all

to perfection.

FRONT END

Every amt. Coronet I have ever seen has a factory flaw on the Hood support !

Every amt. Coronet I have ever seen has a factory flaw on the Hood support !

This was filled in with a small piece of sheet plastic.

The

Points on the fenders were too sharp and would break very easily, so we created

an insert behind the bumper location.

The loops for the bumpers to be attached were also weak,

so we wrapped sheet plastic around them and connected them to the new bumper

molding.

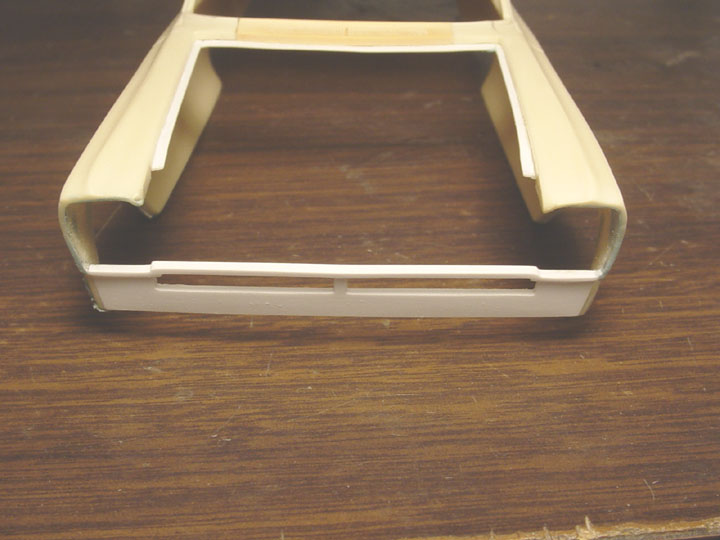

SINGLE

AND DOUBLE HEADLIGHT GRILLS

Because

some cars ran a single headlight grill and some ran a double, we decided to

include both grills with our model !

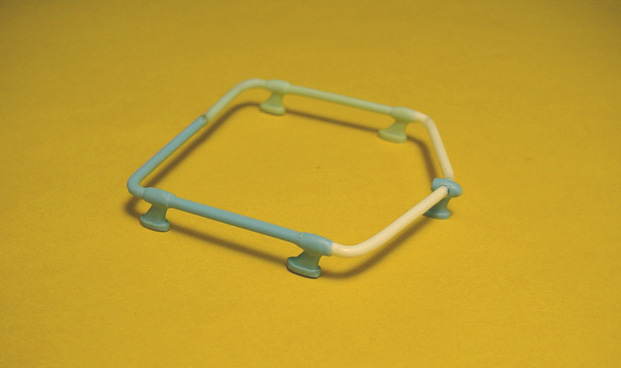

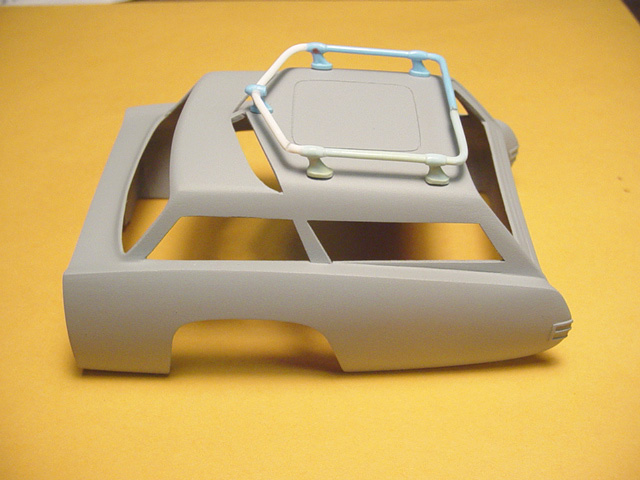

The grill we started

with was too short, so it needed a small strip a plastic all around the edge

of the frame,

The grill we started

with was too short, so it needed a small strip a plastic all around the edge

of the frame,

then it needed putty to re-form the lip around the sides.

Also

you can see were adding Cone Shaped Block out head lights to the single headlight

grill,

these headlights had to be re-sized to fit the headlight buckets.

Here is the double headlight

grill getting the same treatment

!

Here is the double headlight

grill getting the same treatment

!

New Single & Double Headlight grills with Correct Cone Shaped Block outs

!

New Single & Double Headlight grills with Correct Cone Shaped Block outs

!

BUMPERS

The 1965 License plate was

removed from the front bumper and then we created the correct vent grooves.

The 1965 License plate was

removed from the front bumper and then we created the correct vent grooves.

The rear bumper had its 1965

License plate removed as well, along with the original screw mounts.

The rear bumper had its 1965

License plate removed as well, along with the original screw mounts.

A new mount was then added.

WINDOW & DOOR TRIM

It's not understood

why AMT didn't add side window & door trim on their Coronet when it clearly

shows it on the box art for both Ramchargers & Color Me Gone cars.

After

reviewing all the '65 Coronet Funny Cars that ran, it was decided that they

all had some sort of side window and door trim, or at least they still had the molding

that the trim would have been attached to !

The way we plan to do it, you will be able to build any Funny Car car you want,

but may need to remove some trim,

depending on the car you decide to build ?

But, its easier to remove some trim, rather than add it !

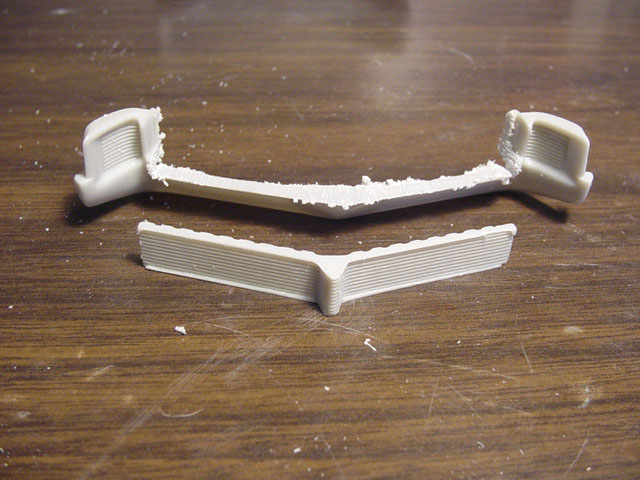

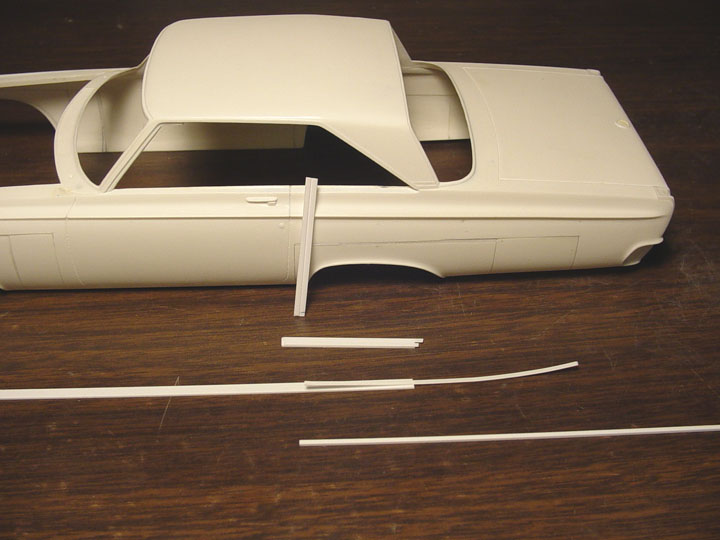

To do the door trim, we started with .020 x .100 evergreen plastic strip, then

2 strips of .010 x .040

To do the door trim, we started with .020 x .100 evergreen plastic strip, then

2 strips of .010 x .040

(shown in the middle). These were glued side by side

leaving a small gap to simulate a weather strip (shown on top).

The side window trim is .030 x

.040 plastic strip, this will be the same thickness as the new door trim.

The side window trim is .030 x

.040 plastic strip, this will be the same thickness as the new door trim.

New side Window and Door Trim,

but still needs a little Liquid glue to fill the cracks and some minor sanding.

New side Window and Door Trim,

but still needs a little Liquid glue to fill the cracks and some minor sanding.

We also fixed the

drip rails on the left side A-pillar that was barely visible on the amt. model.

Here is the finished body

ready for its first shot of primer, it will then be checked for any minor imperfections,

Here is the finished body

ready for its first shot of primer, it will then be checked for any minor imperfections,

re-sanded, primed and then polished to a high gloss.

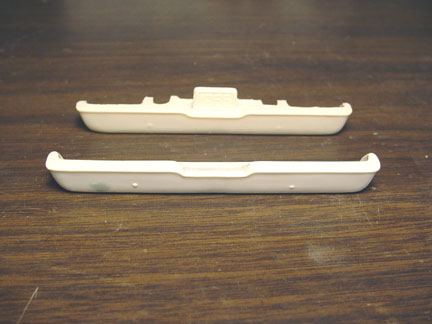

INTERIOR TUB

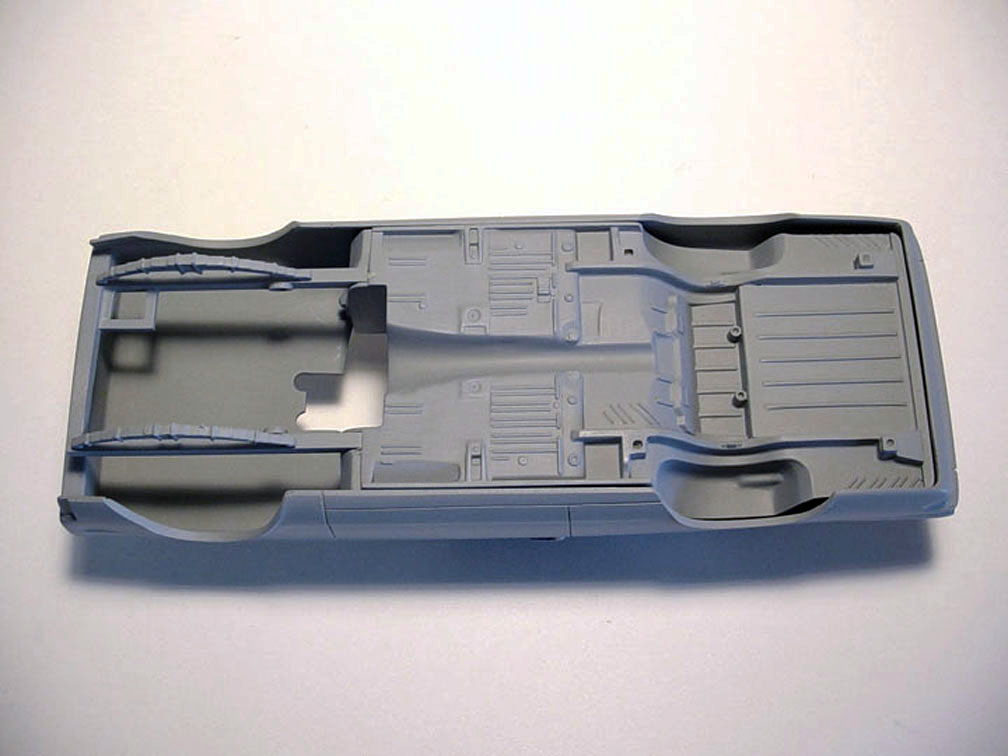

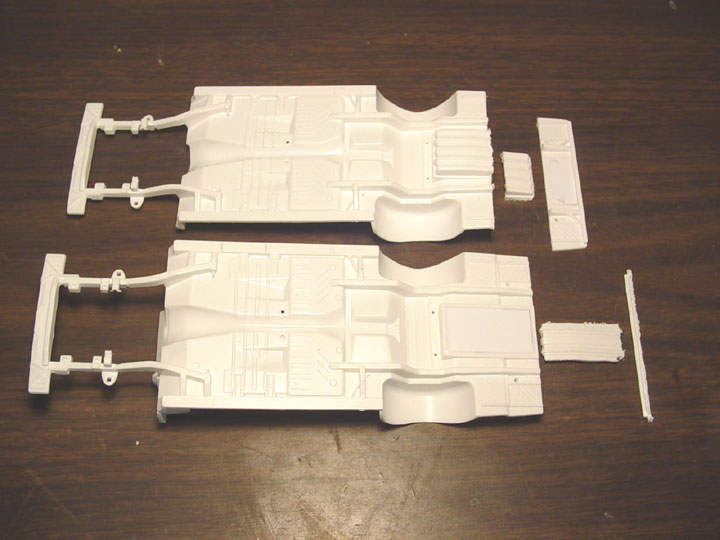

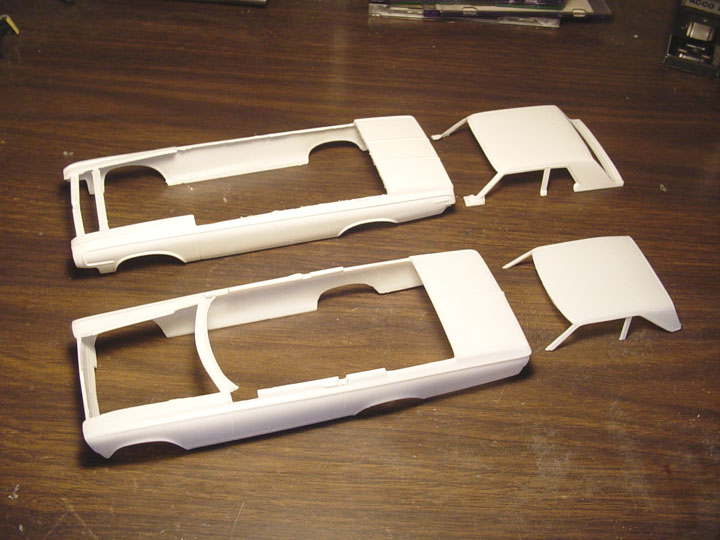

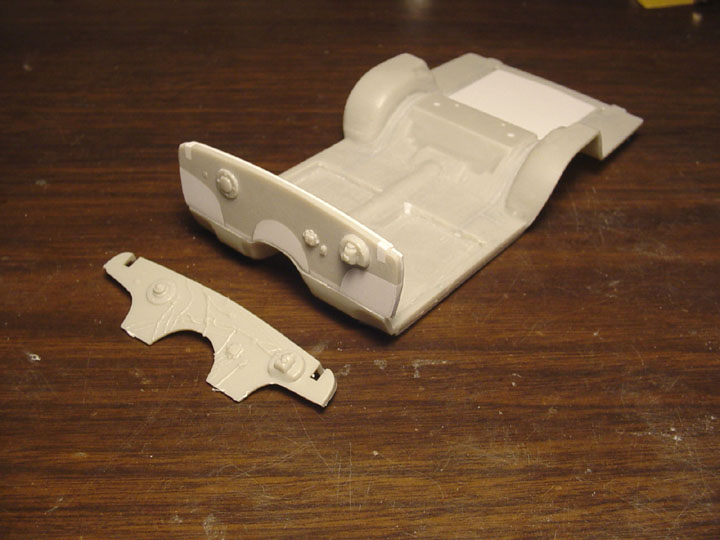

Starting with our '65 Plymouth

A/FX interior tub (bottom of photo) , the door panels were removed.

Starting with our '65 Plymouth

A/FX interior tub (bottom of photo) , the door panels were removed.

Then the door panels from the amt. '65 Coronet were removed from the tub (top

of photo).

The arm rests and window cranks were carefully removed.

Holes were drilled for the

locations of the arm rests, window cranks.

The door handles were taken

from the Ply AFX door panels & glued to the NEW Coronet door panels for

more realism.

We have a new '65 Dodge Coronet

A/FX interior tub !

We have a new '65 Dodge Coronet

A/FX interior tub !

This

master is finished and we guarantee it to be the only "CORRECT"

1965 Dodge Coronet A/FX Hardtop ever offered !

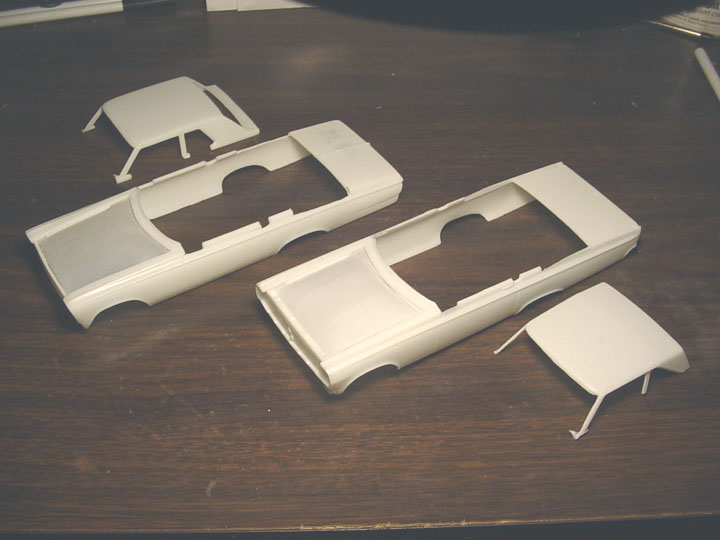

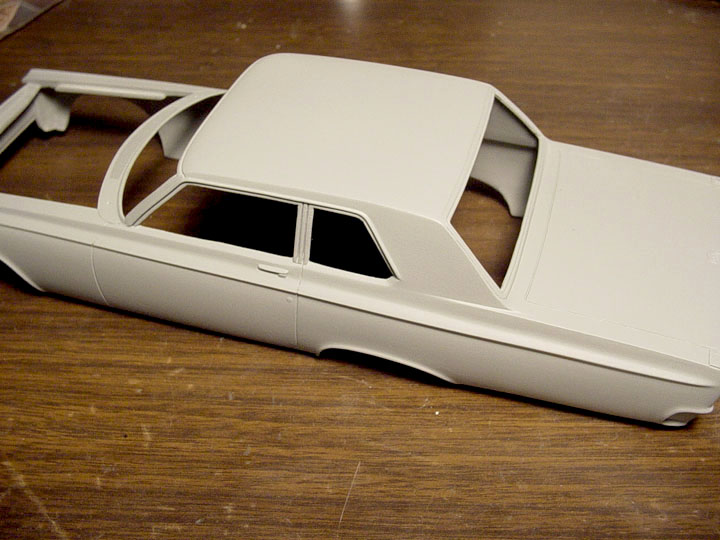

1965 DODGE CORONET SEDAN A/FX

Starting with our '65 Plymouth

Sedan AFX, we removed the roof,

Starting with our '65 Plymouth

Sedan AFX, we removed the roof,

but left some body notches in for a better fit. (this also helps for sanding and body strength).

The '65 Dodge Coronet Hardtop ( that was mastered from an original amt Coronet ) roof was removed and the notches

were lined up to the new Sedan roof.

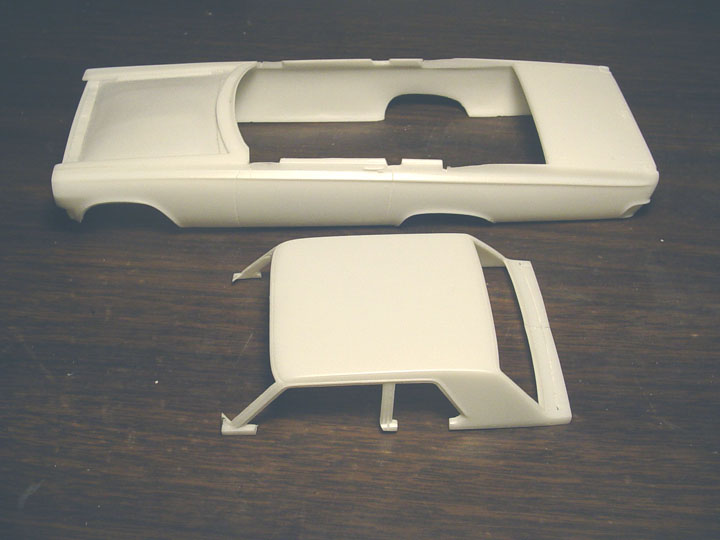

Here is the '65 Plymouth Sedan roof along side the '65 Coronet body.

Here is the '65 Plymouth Sedan roof along side the '65 Coronet body.

The new Sedan roof had to be slit down the center and 3 " were removed,

The new Sedan roof had to be slit down the center and 3 " were removed,

so it can be angled into the front of the 1/4 panel. Here's how all the Pillars

fit into the body.

On the real car, notice how the roof has a seam along the trunk & sail panel.

Our model will have the same.

On the real car, notice how the roof has a seam along the trunk & sail panel.

Our model will have the same.

The new sedan roof is finished !

The new sedan roof is finished !

MASTER MODEL IS FINISHED !

This

model will come with the same parts as the '65 Dodge Coronet Hardtop A/FX

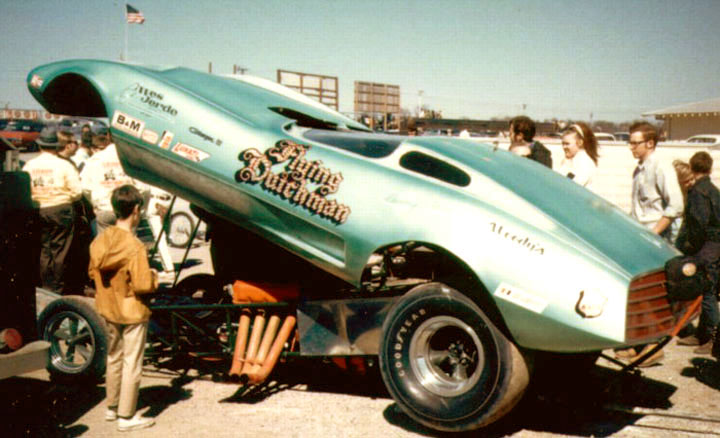

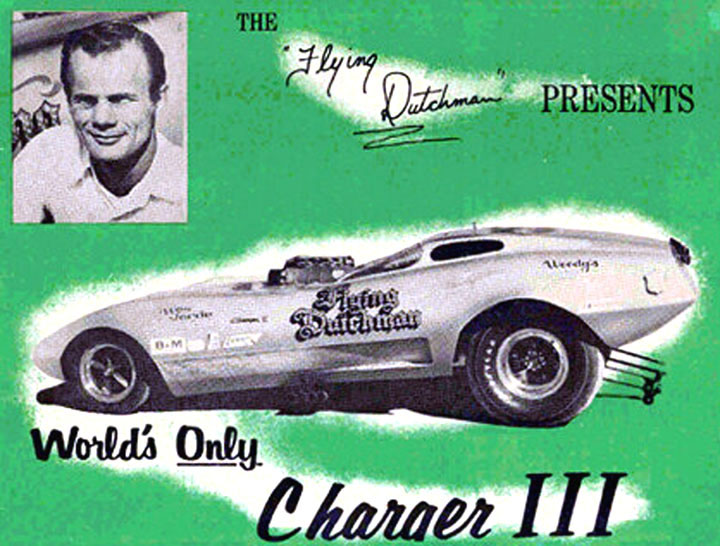

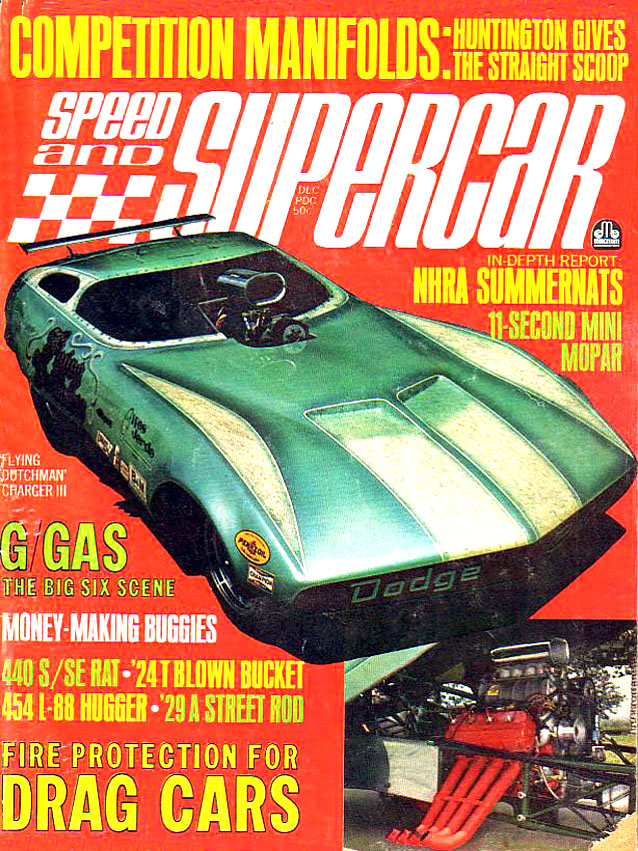

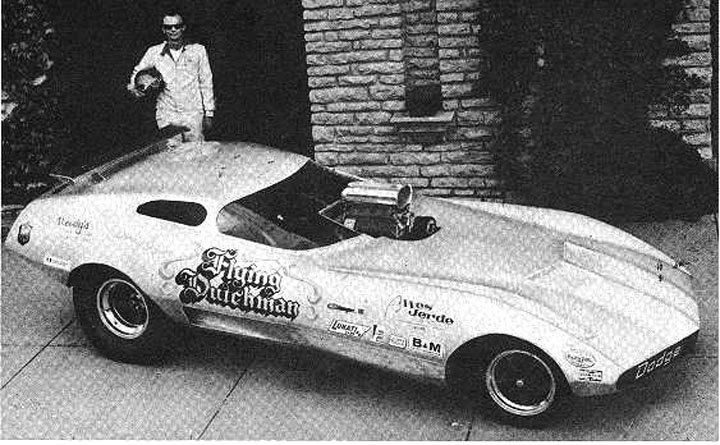

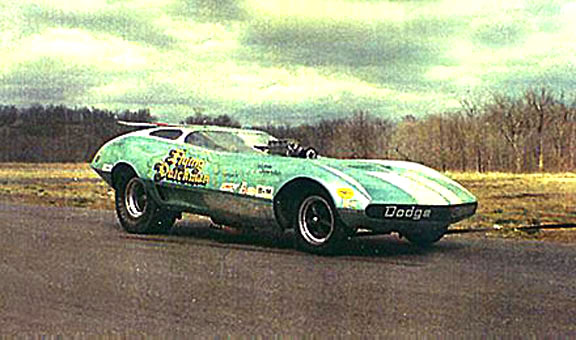

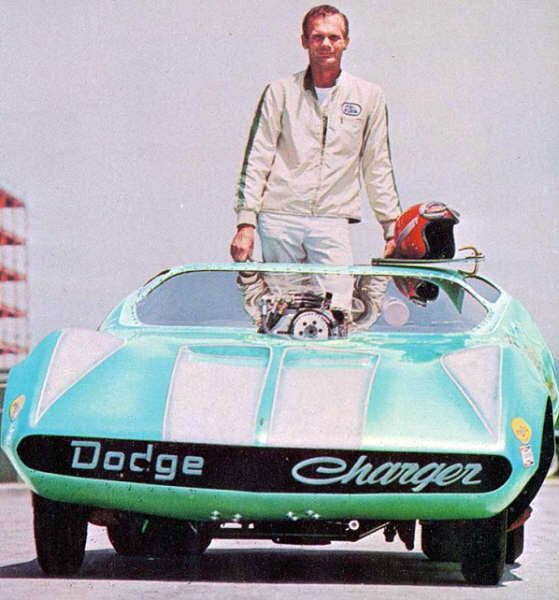

"FLYING

DUTCHMAN"

CHARGER

III F/C

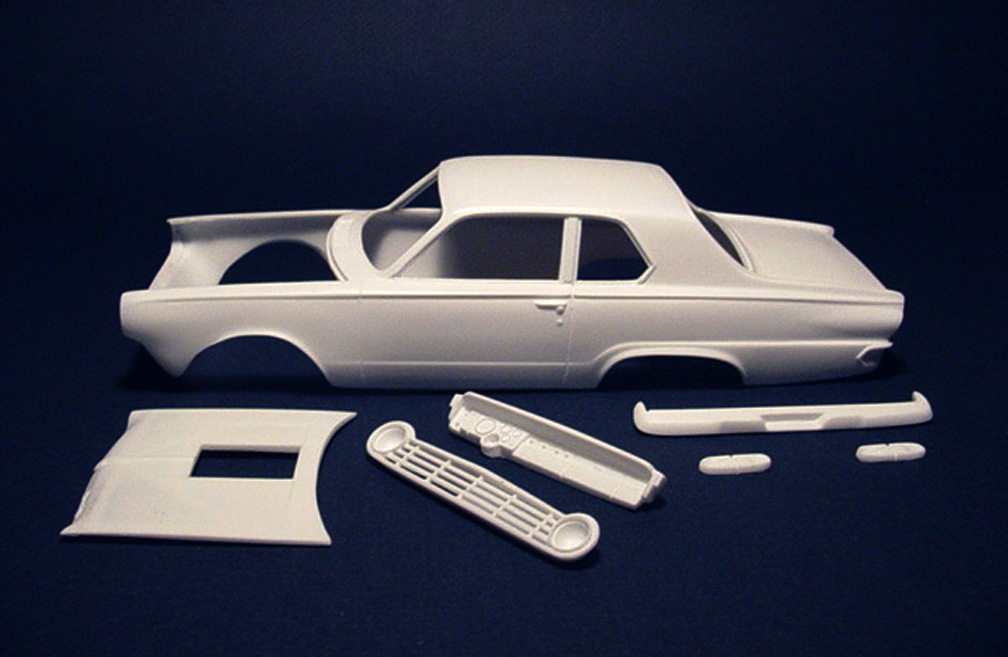

Unlike the original MPC model car; our resin model will have an "accurate body".

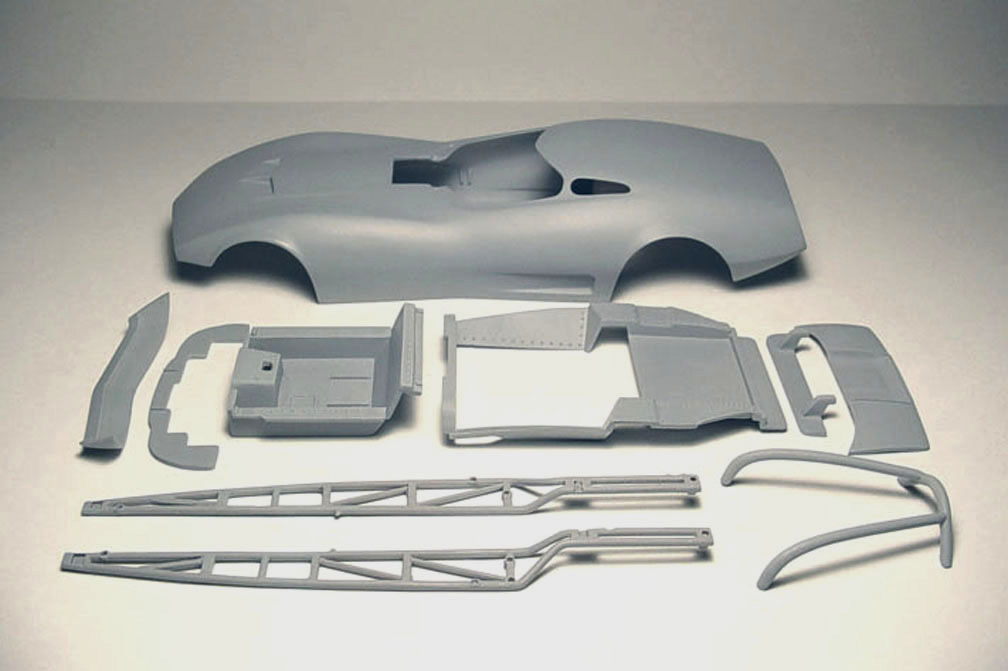

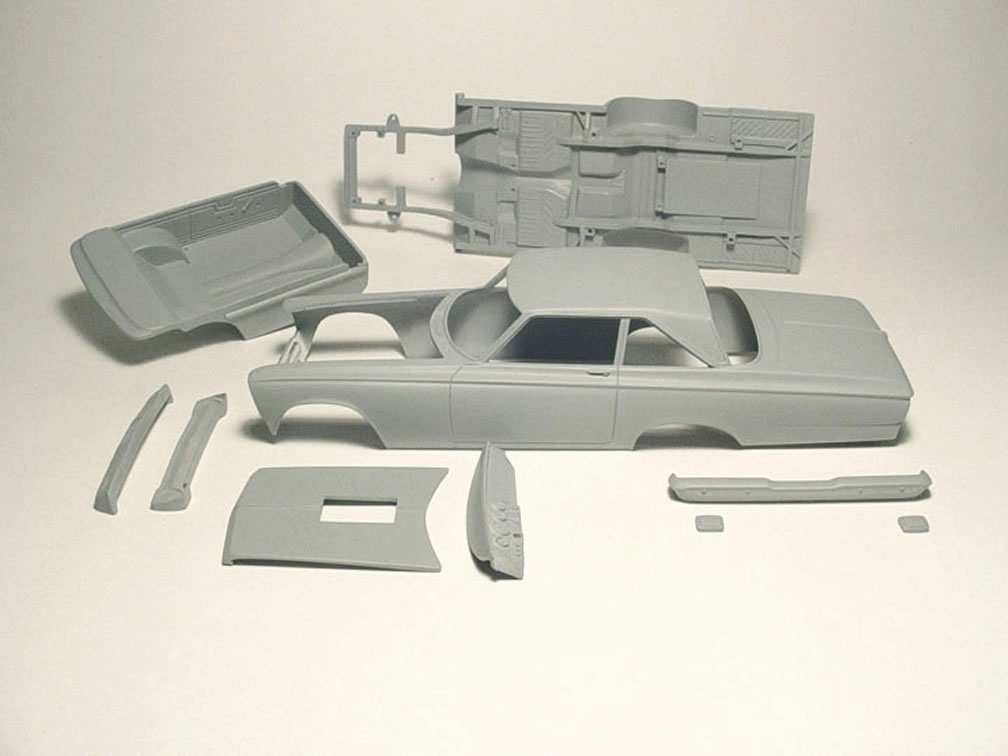

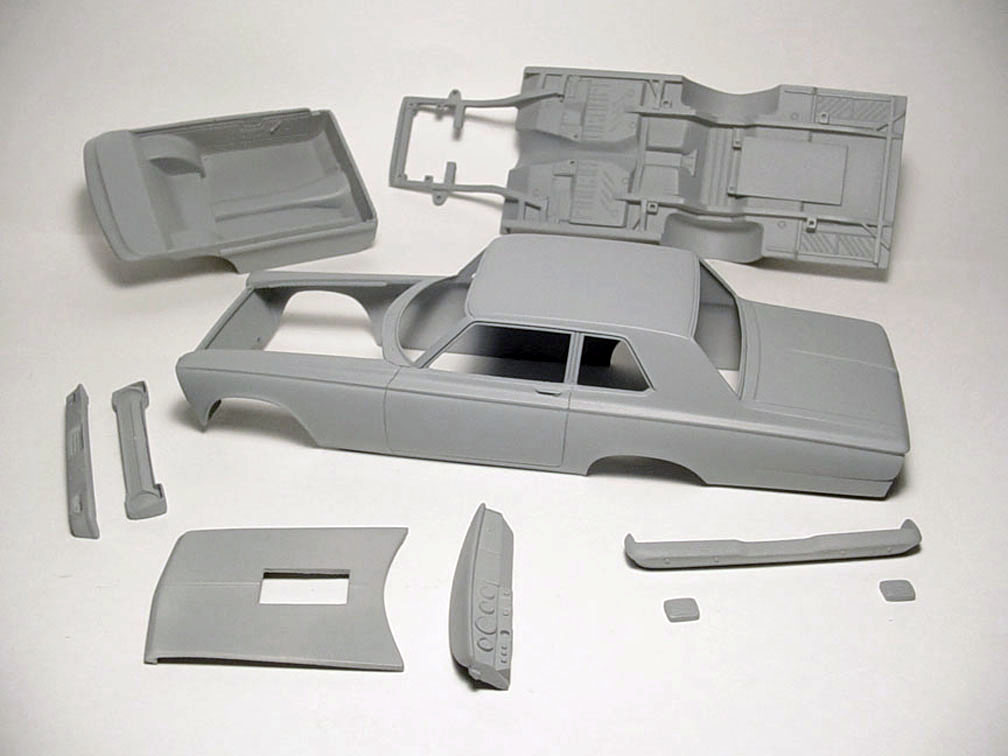

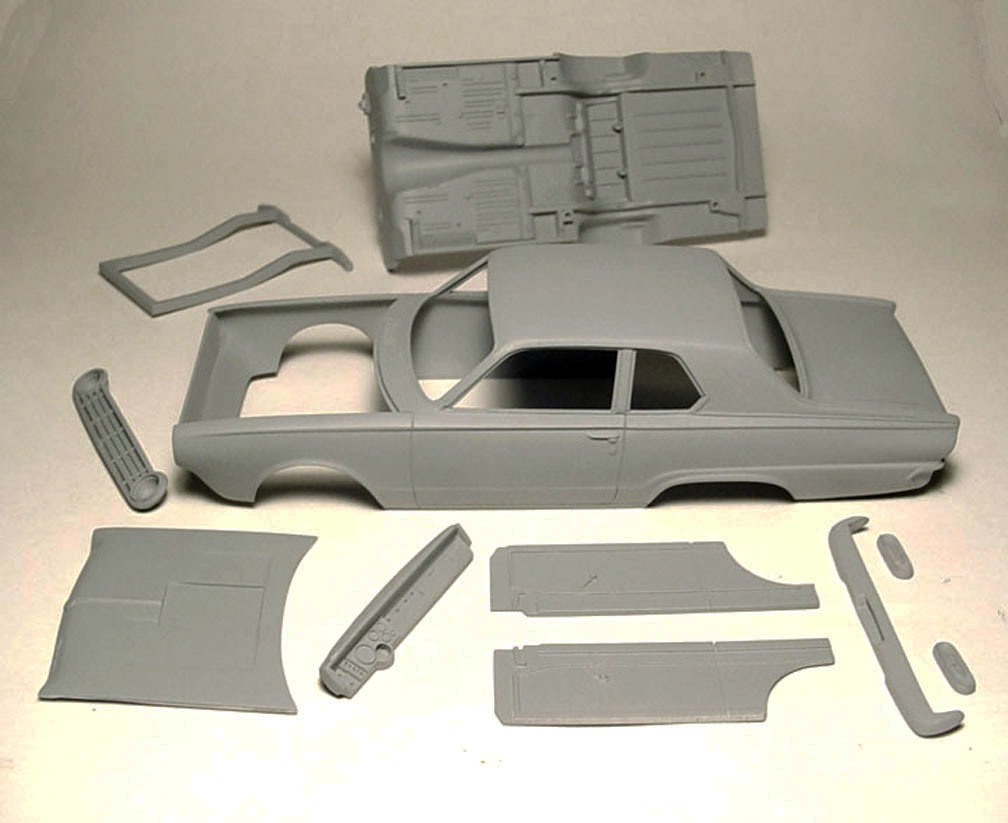

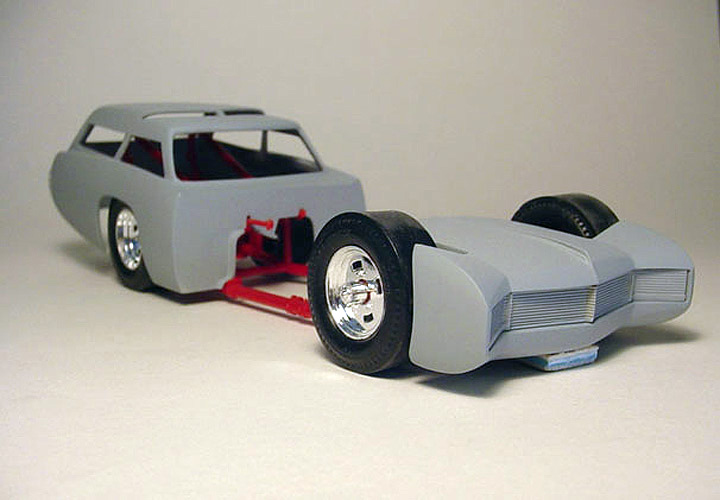

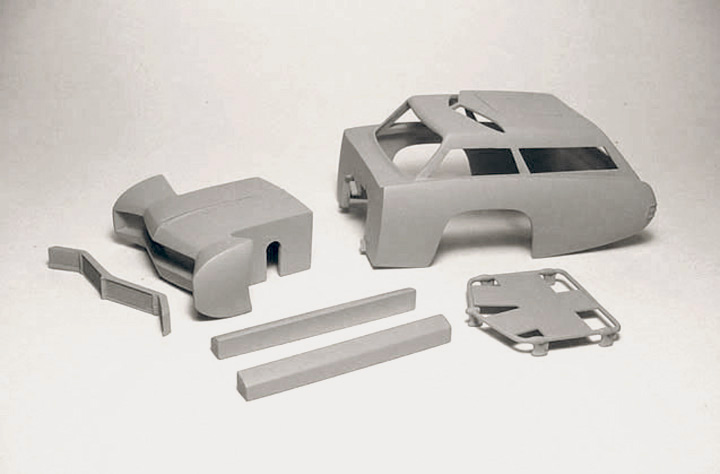

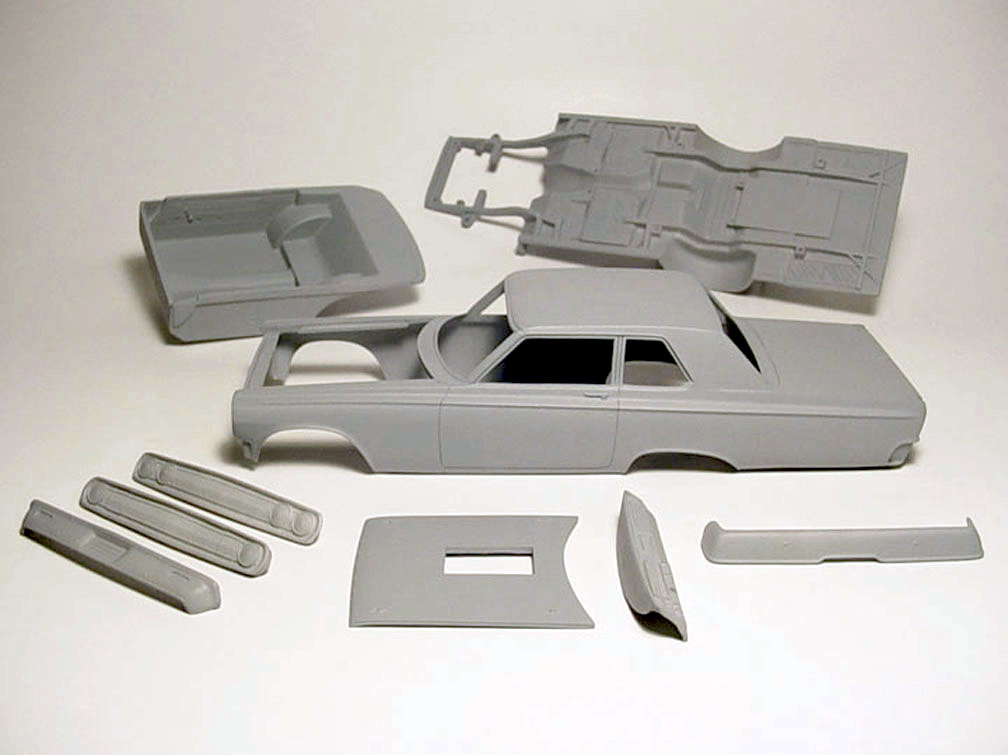

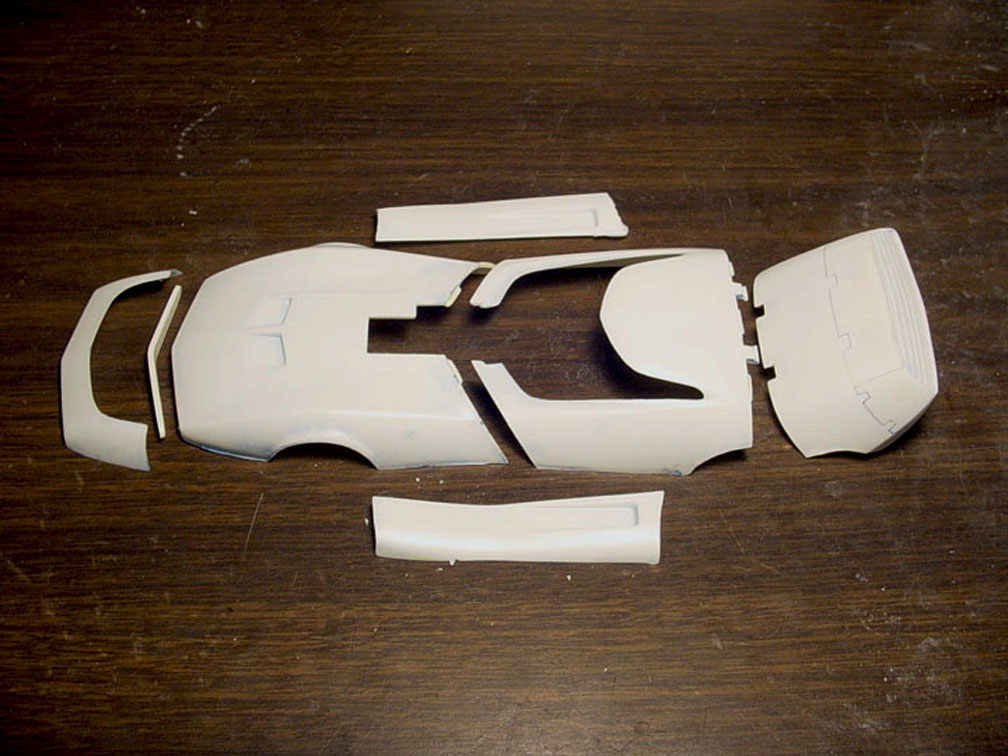

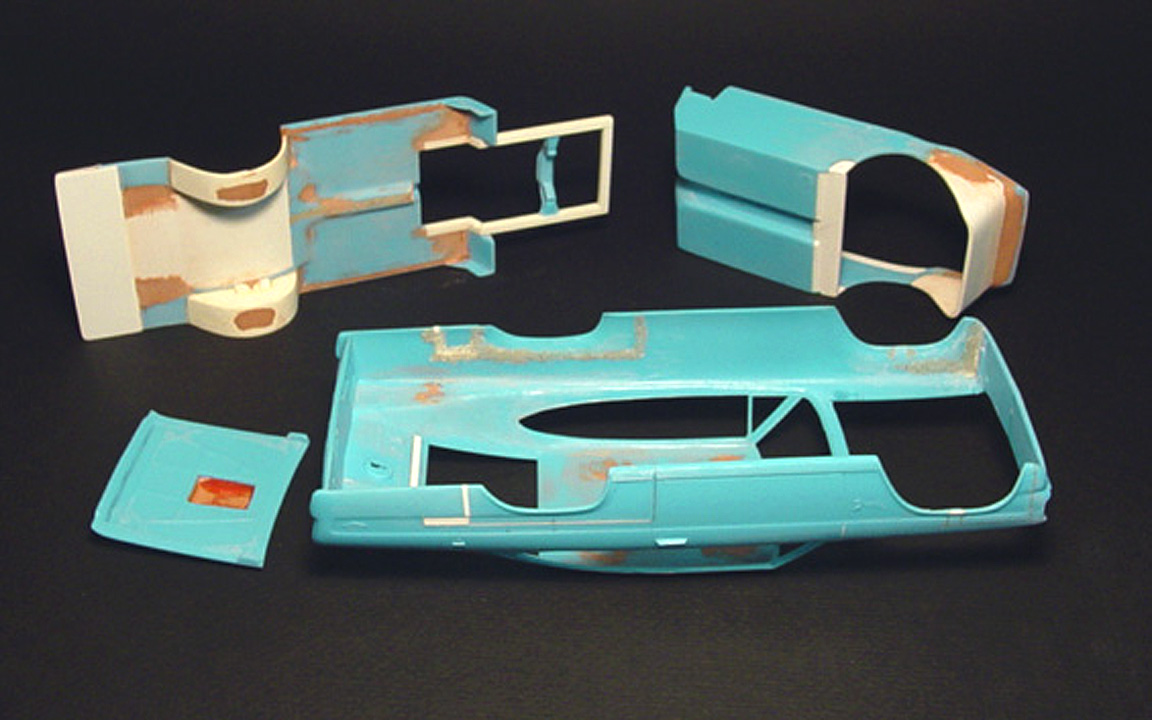

Here is a parts layout of all the original mpc. body parts.

Here is a parts layout of all the original mpc. body parts.

The MPC model was designed wrong; so I will be correcting all the mistakes from the original plastic body.

A- Pillars were added to create side windows.

A- Pillars were added to create side windows.

The rear Valance Panel was removed & will be a separate piece to be able to remove from the mold.

The rear Valance Panel was removed & will be a separate piece to be able to remove from the mold.

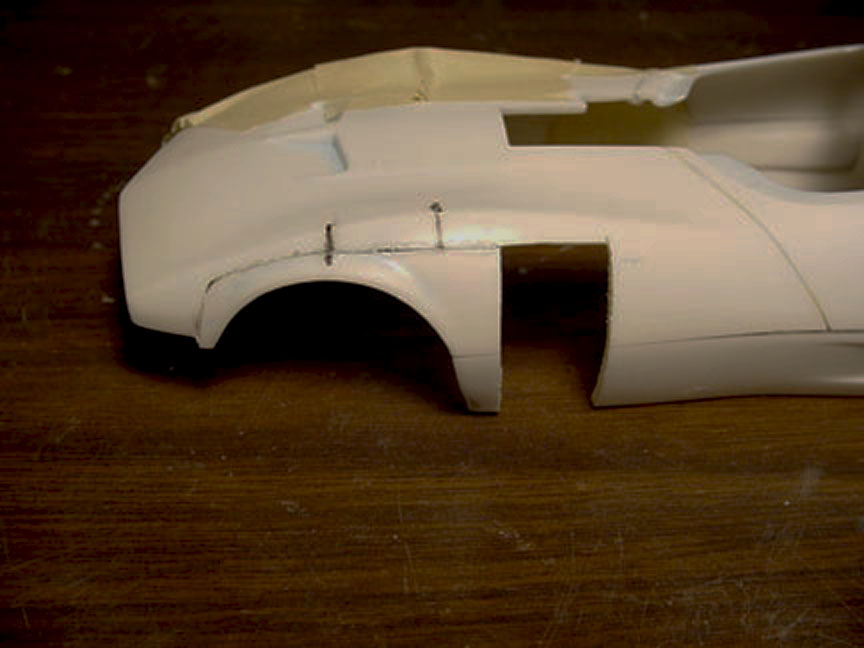

The original rear wheel wells did not have a flare, so masking tape was applied

and was cut out for the shape of the flare.

The original rear wheel wells did not have a flare, so masking tape was applied

and was cut out for the shape of the flare.

Then it was puttied, after removing

the tape, it was sanded and shaped.

The front wheel wells were moved forward 12 scale inches, just as the real car

was !

The front wheel wells were moved forward 12 scale inches, just as the real car

was !

A piece of

sheet plastic will be needed for a patch panel.

This is what the stock mpc.body looked like before Wheel well alteration.

This is what the stock mpc.body looked like before Wheel well alteration.

Here's the New "ALTERED" Front Wheel Wells..... Now its looking like a

Funny Car !

Here's the New "ALTERED" Front Wheel Wells..... Now its looking like a

Funny Car !

A filler panel was needed for the cowl, as the original mpc kit was incorrect.

A filler panel was needed for the cowl, as the original mpc kit was incorrect.

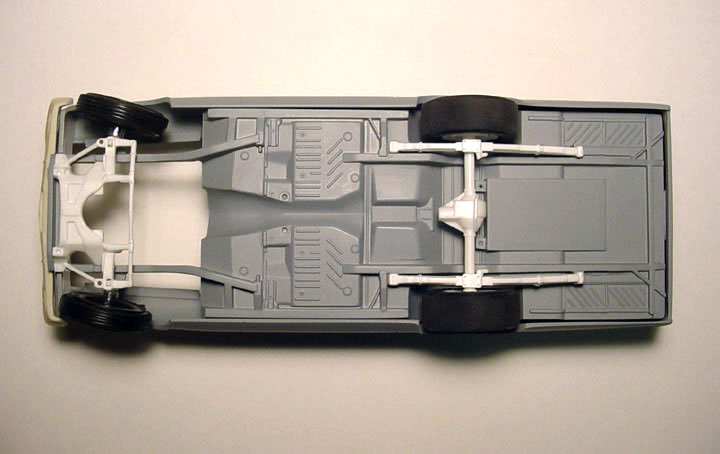

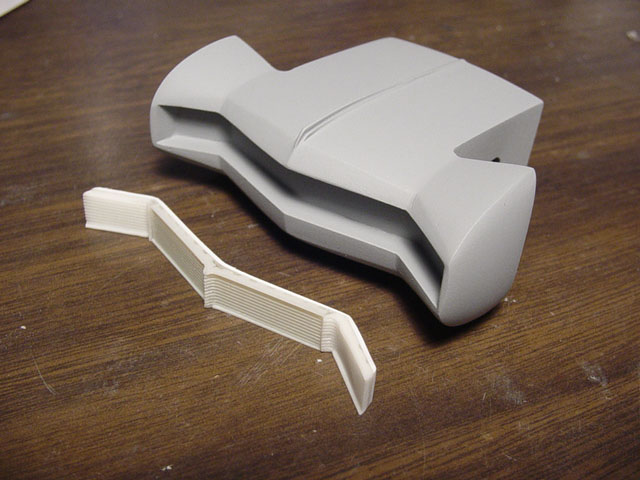

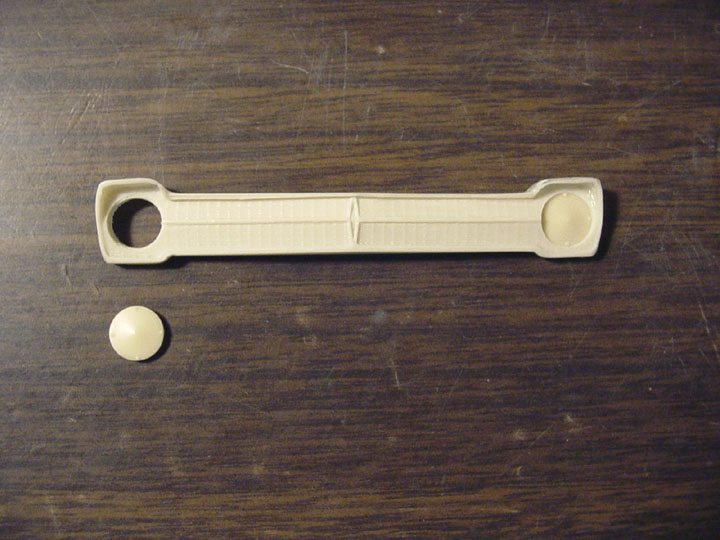

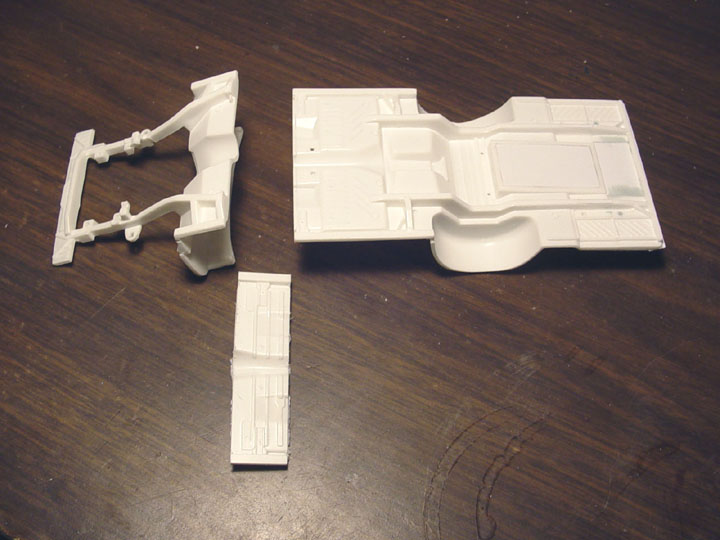

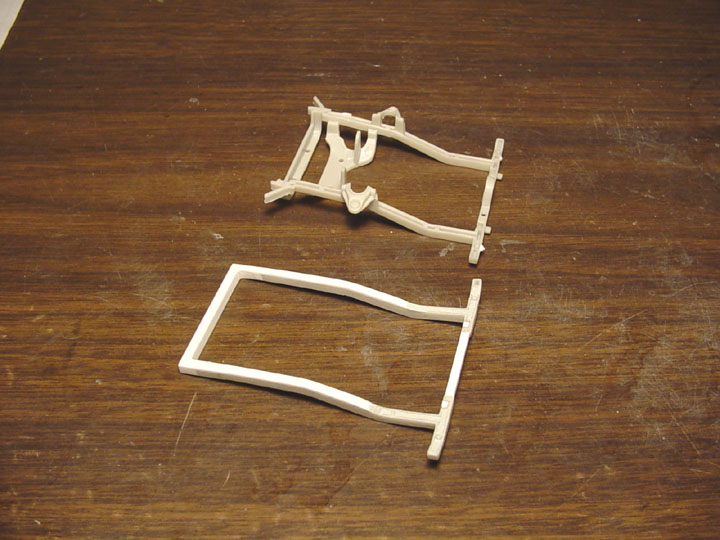

Shown on top is the original mpc. Flying Dutchman F/C frame,

Shown on top is the original mpc. Flying Dutchman F/C frame,

the lower frame

has been stretched to fit our "new Altered Body" and a new mount was installed

to fit the Radius Rods from a,

"Model King" GTO Funny Car or the Kenz

& Leslie Cougar F/C.

Master is finished !

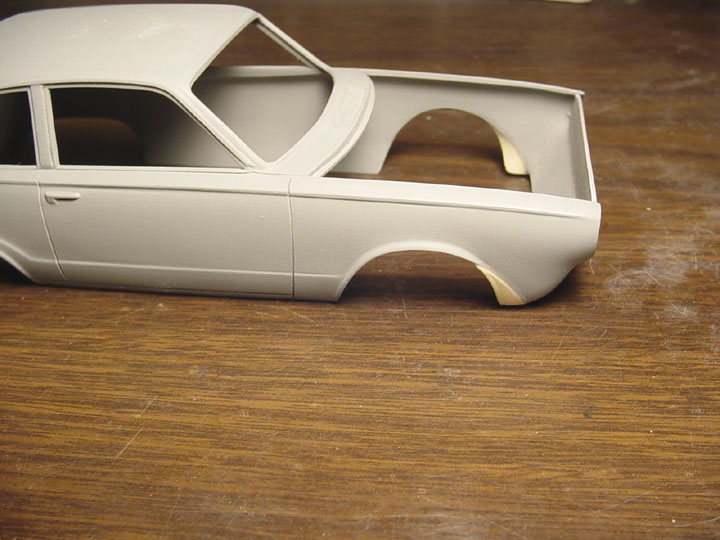

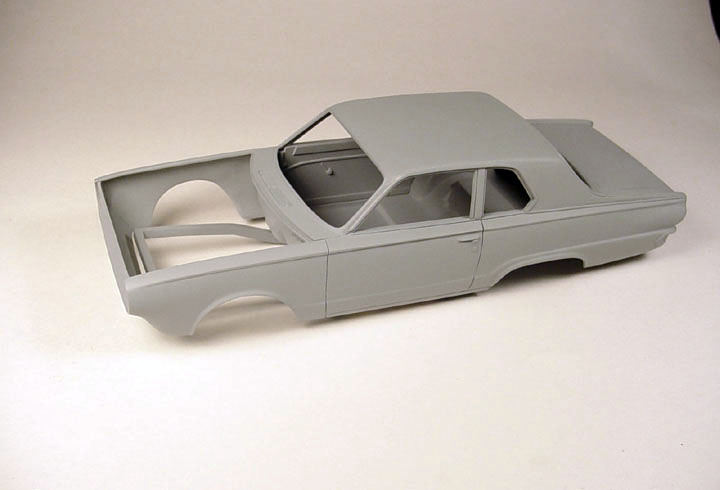

1965 PLYMOUTH BELVEDERE A/FX

(with all new Chassis, Interior parts and Correct A/FX factory specs.)

Starting with an unknown resin body? There were a lot of flaws I needed to fix and a lot of parts that I will need to scratch build.

Starting with an unknown resin body? There were a lot of flaws I needed to fix and a lot of parts that I will need to scratch build.

The

front & rear wheel flares were somewhat washed out, so Evergreen putty was

used to build them up.

The front wheel wells were cut out and moved forward by another 3 scale inches. The

entire body went through a complete re-surfacing.

I wanted to have a separate grill & front bumper, so a mold was made of the Grill/Bumper and one bumper was scraped

to save the grill;

and one grill was scrapped to save the front bumper.

Of all photos I've seen of these A/FX car's, not one had headlights; but they all

had cone shaped headlight covers.

Thankfully,

I have these.... (Thanks to the "Speed City Resin" AFX PARTS PACK).

The headlights were drilled out and the Cone Shaped "Block-out's" were

installed.

Look at the 1:1 '65 Plymouth Grill, notice the middle body valance.... under

the grill.

Look at the 1:1 '65 Plymouth Grill, notice the middle body valance.... under

the grill.

This was not on the original Johan '65 Ply model kit body, and it wasn't noticeable

on the" Grill / bumper part" either.

Count less hours were spent on redesigning the front of the 1/4 panels to perfectly

match the new separate grill.

The correct spear molding was not on the original kit, so a little putty &

carefully taping & sanding and there it is.

Windshield

wipers were removed and the holes were drilled in place.

The cowl vents were really washed out on the original kit and the resin body,

The cowl vents were really washed out on the original kit and the resin body,

so I cut out a cowl

from a Johan '63 Ply Fury resin body I had laying around.

Hood

supports were put in, but I later realized that the hood supports on the cowl need to be removed so the Lindburg Firewall would fit.

The sail panel trim was also washed out, So on goes the reading glasses and

magnifying lamp for some "Plastic surgery".

The sail panel trim was also washed out, So on goes the reading glasses and

magnifying lamp for some "Plastic surgery".

The

top window trim was not very noticeable, so plastic 1/2 round was applied and

sanded down to match other trim.

You'll also notice that the B-pillars were removed....... (because they

didn't have the proper angle).

The

new B-pillars will be done last so they don't brake during all the construction.

The top front window trim was also barely visible, 1/2 round plastic was added

and sanded to match.

The top front window trim was also barely visible, 1/2 round plastic was added

and sanded to match.

The licence plate area was totally incorrect, so one was cut from the same Johan

'63 Ply Fury resin body along with some plastic sheet filler panels.

The licence plate area was totally incorrect, so one was cut from the same Johan

'63 Ply Fury resin body along with some plastic sheet filler panels.

The molded in Taillight Bezels

were also removed as I want to have separate Tail Lights.

The lower spear molding

on the trunk was washed out or sanded off and was built up with Evergreen putty.

Bumper bolts were added to the rear bumper using PRO TECH's - PTMC 7 .040

bolt heads..... A nice added bonus feature !

Bumper bolts were added to the rear bumper using PRO TECH's - PTMC 7 .040

bolt heads..... A nice added bonus feature !

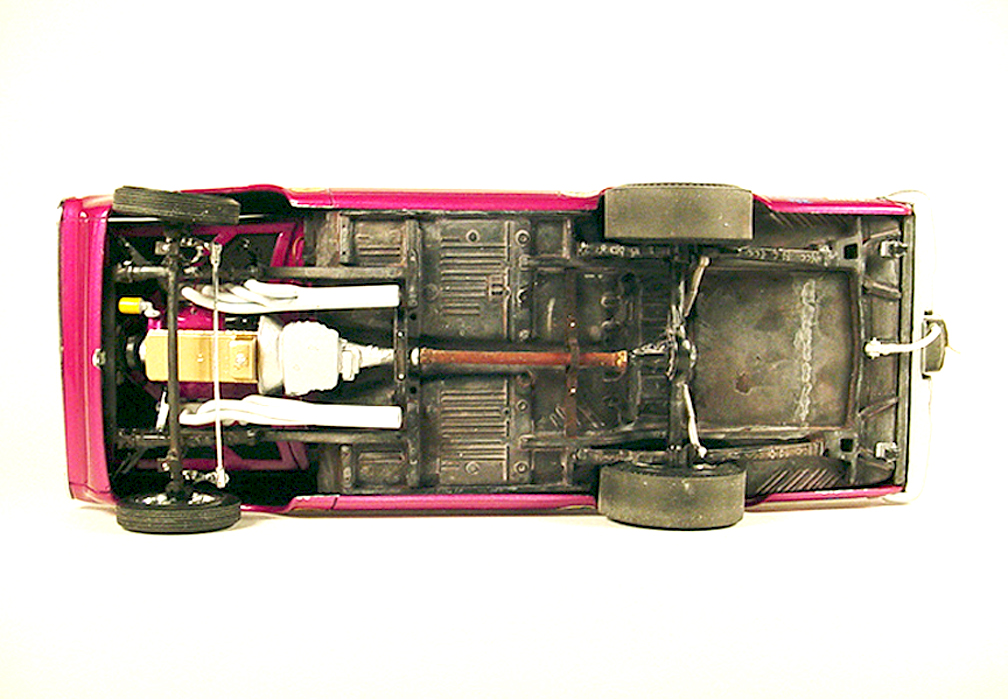

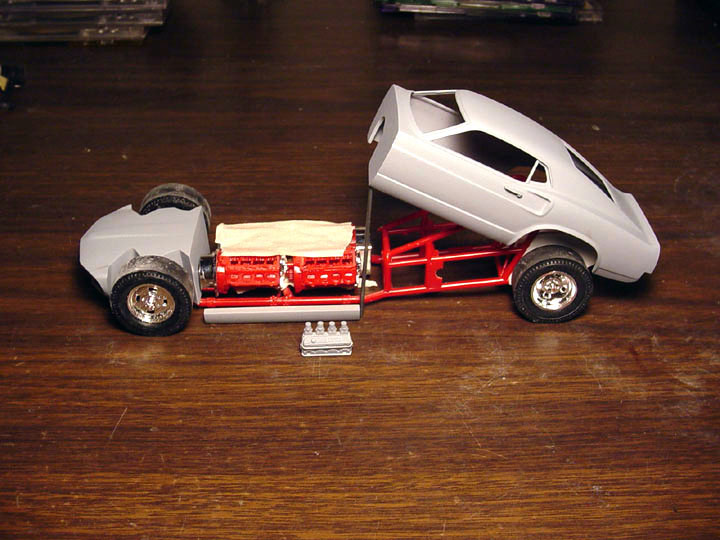

CHASSIS

I wanted to make an all new chassis for this kit as the other one didn't have

good detail and the rear

I wanted to make an all new chassis for this kit as the other one didn't have

good detail and the rear

section of the chassis looked too much like a modern pro stock.

With trying to keep a stock '65 Ply chassis look, I started with a Lindburg

'64 Dodge 330 Chassis as the

'64 Plymouth's had brake lines and just didn't

have the detail as the Dodge had, but there basically the same.

The gas tanks

were removed on both chassis' and rear frame rail on the master was removed.

The other chassis lent its trunk section floor pan and both gas tank holes

were filled with sheet plastic.

The pieces were glued together, to add length

to the new A/FX chassis.

Because the rear wheel wells were moved forward, the chassis had to have some

of the Un i-body

Because the rear wheel wells were moved forward, the chassis had to have some

of the Un i-body

floor pan removed.

The Front wheel wells were moved forward and so the chassis needs to be moved

as well.

The Front wheel wells were moved forward and so the chassis needs to be moved

as well.

Keeping the K-member locations the same, so you can use the supplied Lindburg

kit suspension parts.

Suspension Risers (shackles) were added to the frame, along with Shock Risers, so the Lindburg Dodge

Suspension Risers (shackles) were added to the frame, along with Shock Risers, so the Lindburg Dodge

or Ply. kit suspension parts would have the proper

ride height.

Another fine addition, saving you tons of time by not having

to add it yourself...... We keep the builder in mind.

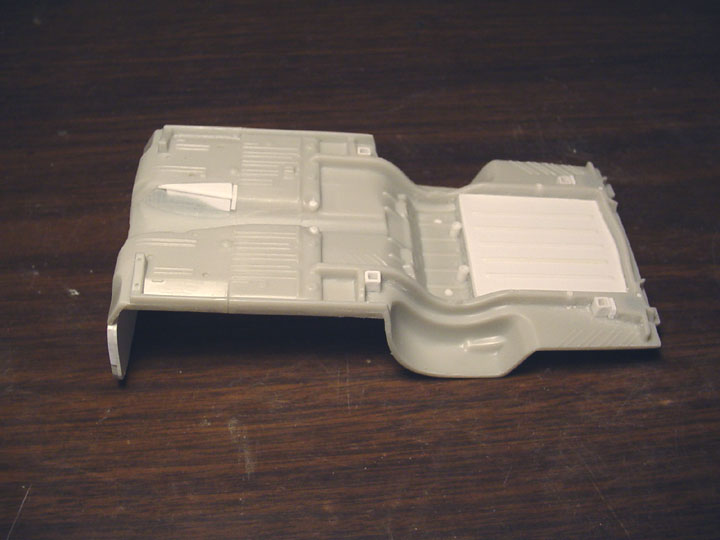

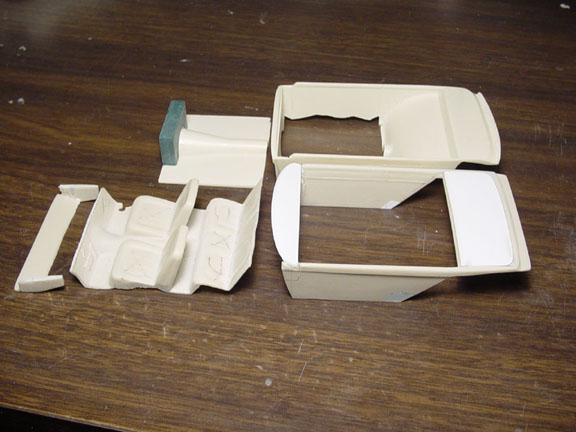

INTERIOR TUB

After getting some requests for an "Interior tub" with door detail and personally test fitting the Lindburg door panels to this this interior Floor

pan,

After getting some requests for an "Interior tub" with door detail and personally test fitting the Lindburg door panels to this this interior Floor

pan,

It was decided that a new Interior tub would need to be made to save

you builder's a lot of frustration.

An old amt

funny car chassis gave up its rear wheel wells, to add to our existing floor

pan.

This is the new '65 Ply Belvedere A/FX Interior tub.

This is the new '65 Ply Belvedere A/FX Interior tub.

The

door panels were reworked from a Lindburg '64 Ply Belvedere and are very close

to '65 Ply door panels.

I've since taken out the window cranks after reading the story about the factory built Ply Belvedere

A/FXer's.

New motor Mounts were added to the stretched frame, by measuring the displacement

of the original motor mounts on the K-member,

New motor Mounts were added to the stretched frame, by measuring the displacement

of the original motor mounts on the K-member,

This will keep the motor at

stock displacement and height. To

raise the front suspension, you can add pieces of plastic to all location

points on frame.

After doing extensive research.... None of these cars had a stock hood.

After doing extensive research.... None of these cars had a stock hood.

So

after carefully measuring where the Injectors will come through, the hole

in the hood was cut out.

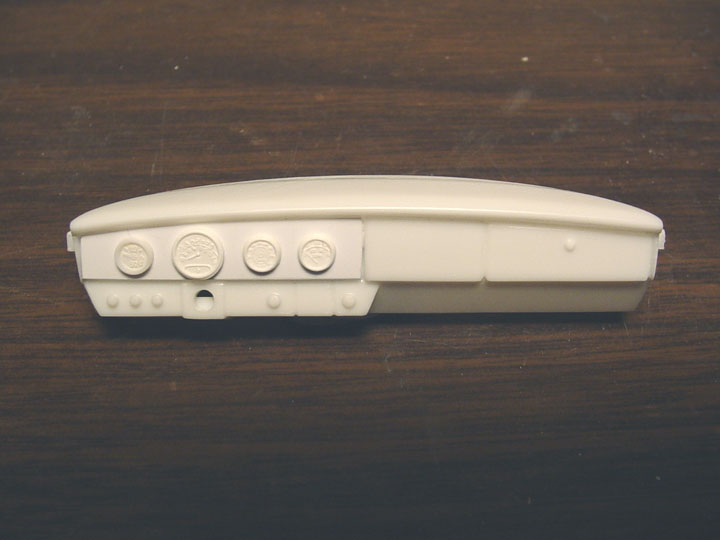

Finally, a 1965 Ply Belvedere A/FX Dash !

Finally, a 1965 Ply Belvedere A/FX Dash !

It

was made by starting with a Lindburg '64 Ply Dash and adding Plastic Sheet

to fit the '65 Ply Cowl. (photo 3)

A new plastic insert was made to fill in the area from the original kit Instrument

Cluster. (photo 1)

New

Gauges, Including a Tachometer, Oil Pressure, Temp. & Voltage Meter. (photo

2)

Master model is shown before installation of motor mounts & before hood was cut out.

The master is finished and I guarantee it is the only correct '65 Ply A/FX Hardtop ever offered !

This NEW '65 Ply A/FX will come with "CORRECT" Body, Hood, Grill, Bumpers, Taillights, Interior Tub, Dash & Chassis.

"

YOU GET A BIGGER BANG FOR YOUR BUCK " at ![]()

1965

PLYMOUTH SEDAN A/FX

Ron

Ramsey stopped by to help us with this project,

it was a great time and we had

a lot of laughs !

After

carefully planning we decided where to make the cuts on a Lindburg '64 Dodge

to be grafted to our '65 Ply Belvedere AFX.

The Lindburg '64 Dodge

(above) gave up its roof to put on our "Speed City" '65 Belvedere

A/FX body (below).

The Lindburg '64 Dodge

(above) gave up its roof to put on our "Speed City" '65 Belvedere

A/FX body (below).

Here is the '64 Dodge Sedan roof being

test fitted to our '65 Ply Belvedere AFX body.

Here is the '64 Dodge Sedan roof being

test fitted to our '65 Ply Belvedere AFX body.

The rear of the '64 Dodge roof needed to be cut down the middle of the window

trim & trunk,

so it could be widened to correctly fit the '65 Ply body.

The master is finished and we guarantee it is the only correct '65 Ply Sedan A/FX ever offered !

NEW '65 Ply Sedan A/FX will come with "CORRECT" Body, Hood, Grill, Bumpers, Taillights, Interior Tub, Dash & Chassis.

1965 DODGE DART A/FX

This was

the first Speed City model put into production on July 7 2006.

This master

model is getting a new face lift (2008) and extra parts with

new AWB Chassis, Frame & Interior Tub.

The first

thing was to re-surface the entire body & Hood.

The first

thing was to re-surface the entire body & Hood.

The Inside body of

the body was thinned.

A rear trim molding was added to the top of the rear fender....... We

couldn't do this to the original model,

as it would have been to hard to remove it for all the other Dodge Darts

we planned on doing.

Next, It was decided to rebuild the front wheel well as they were cut out

for the "Rambunctious Dart".

Next, It was decided to rebuild the front wheel well as they were cut out

for the "Rambunctious Dart".

This new wheel well gives the new body some alternatives for the builder.

This new wheel well gives the new body some alternatives for the builder.

This is the original body with the hogged out front wheel well.

This is the original body with the hogged out front wheel well.

CHASSIS

64 pieces of Evergreen & Plastruct plastic sheet, half round, strip and tube were used to complete this new chassis.

Starting with an amt/ertl '71 Plymouth Duster 340, The gas tank was removed

& all holes filled.

Starting with an amt/ertl '71 Plymouth Duster 340, The gas tank was removed

& all holes filled.

21 scale inches were removed from the floor pan, the chassis was then super

glued back together.

and

an extension was built to the trunk section to fill the gap.

Starting with a '66 Barracuda firewall, The side panels & holes for the

hood brackets were filled in.

Starting with a '66 Barracuda firewall, The side panels & holes for the

hood brackets were filled in.

all wires were sanded off, but the master cylinder, water heater housing,

ground

bolt & electronics box were left on, which gives the firewall some nice

detail !

The '71 Duster front frame clip need to be simplified for drag racing.

The '71 Duster front frame clip need to be simplified for drag racing.

Extra

plastic strips were used to fill in the frame holes. and a solid square tube

was used for the front frame rail.

The door panels are all scratch built from plastic sheet, flat strip, square

strip and half round.

The door panels are all scratch built from plastic sheet, flat strip, square

strip and half round.

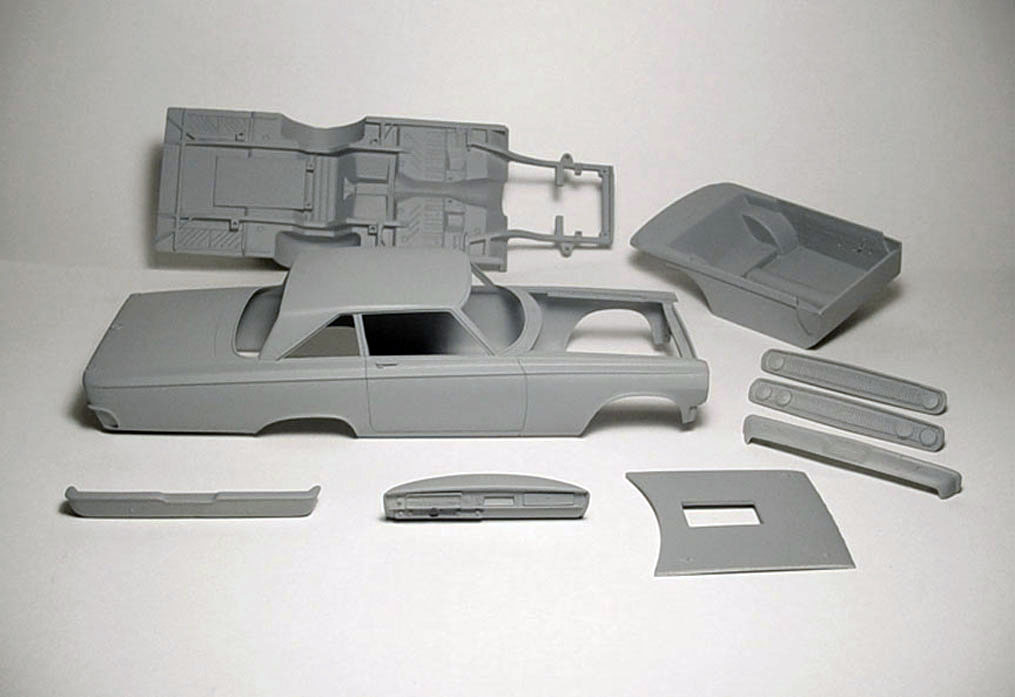

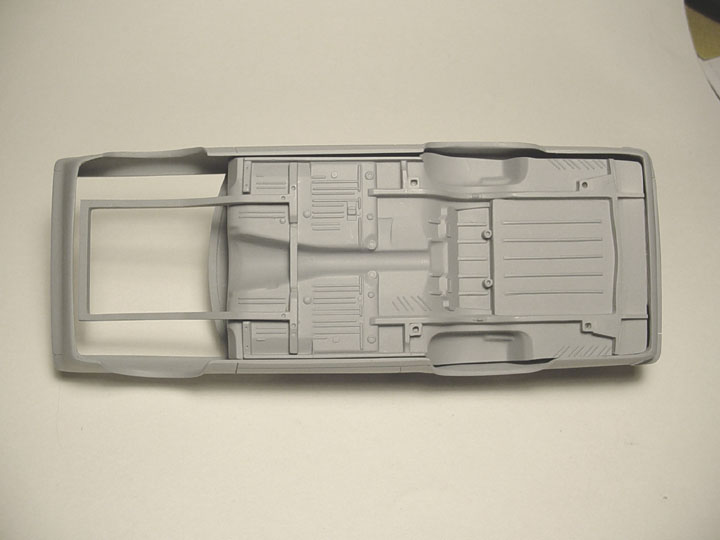

These are the new pieces that will be added to the '65 Dart AFX #SC-1.

These are the new pieces that will be added to the '65 Dart AFX #SC-1.

Check out how nice this new chassis looks, it's even better than my original chassis I built for myself.

Check out how nice this new chassis looks, it's even better than my original chassis I built for myself.

The

'71 Duster rear end & suspension will fit, or you can create your own

from the parts box ?

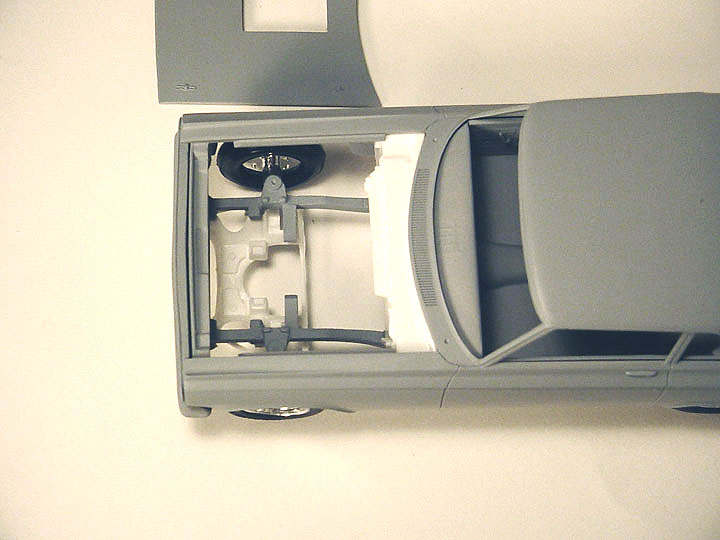

Here's a top view showing how well the Interior door panels fit.

Here's a top view showing how well the Interior door panels fit.

Door panels have braces for the dash board to be glued to......... another

bonus !

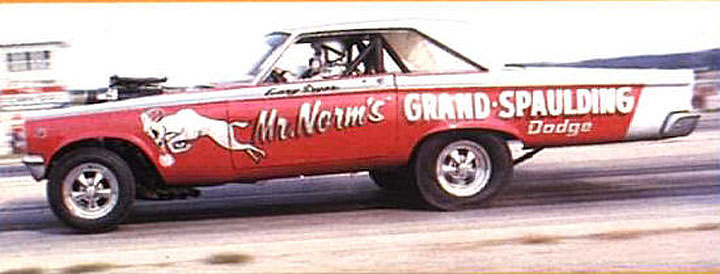

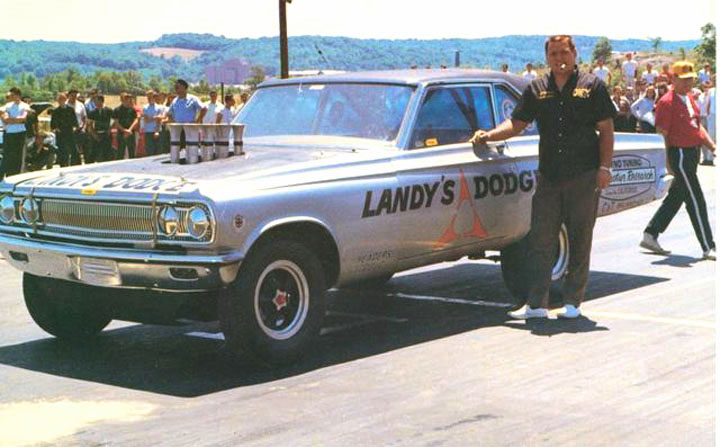

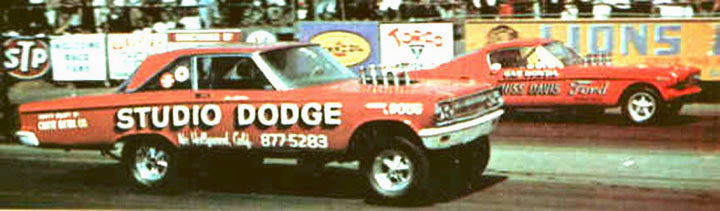

'66 LONG DART FUNNY CAR

As you can see by the photos here, every Dart funny car had differences,

long nose/short nose,wheelbase,stock bumper/ cut bumper, etc, etc.

It took several days just to come up with an idea to make one

Body, Chassis & Interior Tub

to do any version of the'66 Dart F/C bodies.

It took several months to do all the research, design &

painstaking labor !

You will need to make some alterations to do any individual

car. Though with this set up, Any individual car can be done.

2- rear 1/4 patch panels will be supplied to do the rear wheel

alterations ( if needed) some ran stock location wheel wells.

We will also add a printable instruction sheet to make the

"shorter front clip" cars, (most are shown on the second row).

Extreme amounts of time were put into research and designing

this model to make sure it will be as accurate as possible.

BODY WORK

Our '66 Semi-Stretched

LANDY DART was taped off to cut 6 scale inches ahead of its already 6" stretch,

Our '66 Semi-Stretched

LANDY DART was taped off to cut 6 scale inches ahead of its already 6" stretch,

giving the front clip the correct factory fiberglass one foot stretch !

Our '66 LANDY DART ( front

clip) cut off and our '66 Stock Dodge Dart ( body in back ground ).

Our '66 LANDY DART ( front

clip) cut off and our '66 Stock Dodge Dart ( body in back ground ).

The '66

Stock Dart body needed to have several alterations done before we could mate

the two bodies together,

including new door handles.

'66 LONG DART body ready

for final sanding & polishing. (hood was left in for integrity

reasons,

'66 LONG DART body ready

for final sanding & polishing. (hood was left in for integrity

reasons,

though hood can easily be scribed out with the back a razor knife

INTERIOR TUB

Starting with our '66 Stock Dodge Dart Interior

Tub ( shown in Front ) and our

Starting with our '66 Stock Dodge Dart Interior

Tub ( shown in Front ) and our

" HAIRY CANARY" Valiant Interior tub ( shown in Rear ).

Saving the floor from the "HAIRY CANARY"

( because of its enlarged tranny tunnel ) & using the interior sides

Saving the floor from the "HAIRY CANARY"

( because of its enlarged tranny tunnel ) & using the interior sides

&

package tray from a '66 STOCK DART , the two were mated together along with

a large engine housing ( in green plastic).

The '66 Dart stock interior had all its arm rest's,

door handles & window cranks removed.

The '66 Dart stock interior had all its arm rest's,

door handles & window cranks removed.

*saving the top of the door moldings*

New correct door handles were installed, along with kick plates.

New sheet

was added for firewall, angled flat dash and rear seat area.

Notice how motor will sit back ( if needed ). 23

separate pieces were used to create this "ONE OF A KIND" interior

tub.

Notice how motor will sit back ( if needed ). 23

separate pieces were used to create this "ONE OF A KIND" interior

tub.

We mastered this interior tub to resemble Gene

Snow's "RAMBUNCTIOUS" funny car.

We mastered this interior tub to resemble Gene

Snow's "RAMBUNCTIOUS" funny car.

Although it will fit any other

Dart funny car you plan to build !

Shows how interior

fits to body, clearance was used to accept windows

Shows how interior

fits to body, clearance was used to accept windows

( use .010 clear or tinted

plastic sheet for glass ).

CHASSIS WORK

Here you can see how any displacement of front and rear wheels

can be archived,

Here you can see how any displacement of front and rear wheels

can be archived,

second frame brace can be used when body is cut back one

scale foot (a full scale half inch ).

Motor mounts can also be moved if needed

? (notice patch panels to do rear wheel well alterations.

Shows how to tape on pencil lines and remove stock

location wheel wells and

Shows how to tape on pencil lines and remove stock

location wheel wells and

add altered wheel well "Patch Panels".

MASTER IS FINISHED

This new resin

kit will come with the only "CORRECT" '66 Dodge Dart Funny Car Body,

Chassis, Interior tub,

Front grill, Bumpers, Taillights & Two ( left &

Right ) 1/4 Patch panels.

1967 BUICK SKYLARK G/S 400

Originally, I was only going to do the Funny Car version,

but I got some interest from others to do a full stock version as well.

TRUNK, BUMPER & TAILLIGHTS

Starting with a vintage 1966 Buick model, The interior of the body was cleaned up of all it's mess.

Starting with a vintage 1966 Buick model, The interior of the body was cleaned up of all it's mess.

The back of the bumper and the tops of the 1/4 panels and trunk was filled in with putty, since all these parts will need to be reshaped.

Here you can see the original '66 Buick bumper assembly.

The tail lights and lenses came from the parts box.

The tail lights and lenses came from the parts box.

The tops of the tail light shrouds were made from sq. plastic strip and the leading edge of the trunk trim was also made from strip.

After making the tail light bezels to fit, 2 pieces of .010" round was used between the 2 red lenses'.

After making the tail light bezels to fit, 2 pieces of .010" round was used between the 2 red lenses'.

The rear bumper was re-shaped and .020" sheet was used top create a step in the bumper.

The 1966 license plate was removed and new directional's were cut into the .020" sheet.

The sheet was then super glued to the bumper.

The top of the trunk had new chrome trim added by using H.O. scale train lap siding for scale houses.

The tail lights were then glued to the bumper.

Here's how all the parts are fitting so far..... Notice the newly shaped trunk lid.

Here's how all the parts are fitting so far..... Notice the newly shaped trunk lid.

I almost forgot..... A new trunk lock was cut from another model and added.

I almost forgot..... A new trunk lock was cut from another model and added.

'67 BUICK GRILL

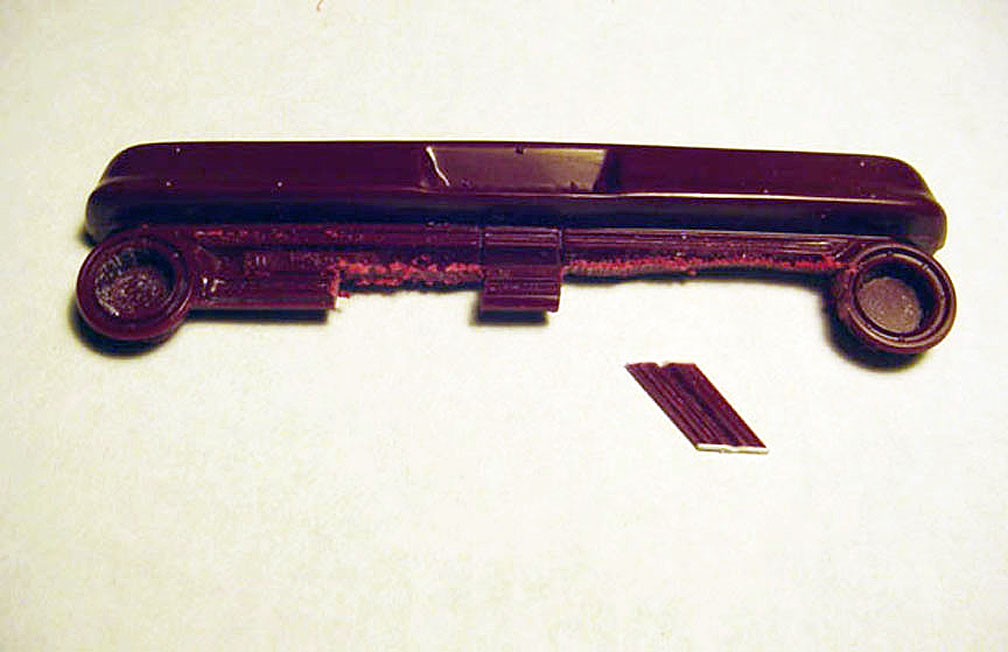

To do a new '67 Buick grill, I started with a red parts box grill that had the same dual headlight bezel shape I needed.

To do a new '67 Buick grill, I started with a red parts box grill that had the same dual headlight bezel shape I needed.

The tops of the bumper protrusions also need to be re-shaped.

Another center bar was added using .020" plastic strip. Small head light lenses were reversed and glued in to be used as backing plates.

Another center bar was added using .020" plastic strip. Small head light lenses were reversed and glued in to be used as backing plates.

A photo-etched G/S badge was applied.

A photo-etched G/S badge was applied.

HOOD

The '66 Buick hood was glued to the body and back filled with plastic.

The '66 Buick hood was glued to the body and back filled with plastic.

Yes, it would have been nice to have a separate hood, but I'm mainly building this model to be used as the Funny Car version and.....

It will make all the hood alterations to be easier.

All the detail on the '66 Buick hood was removed and a piece of .020" sheet was used to create the lift in the center of the hood that is needed

to make this into a '67 Buick hood.

Putty is being used to make a newly shaped hood.

Putty is being used to make a newly shaped hood.

A .020 x .020" strip was used to make a center crease in the hood.

A .020 x .020" strip was used to make a center crease in the hood.

We now have a 1967 Buick Skylark hood & Grill.

We now have a 1967 Buick Skylark hood & Grill.

HOOD SCOOPS

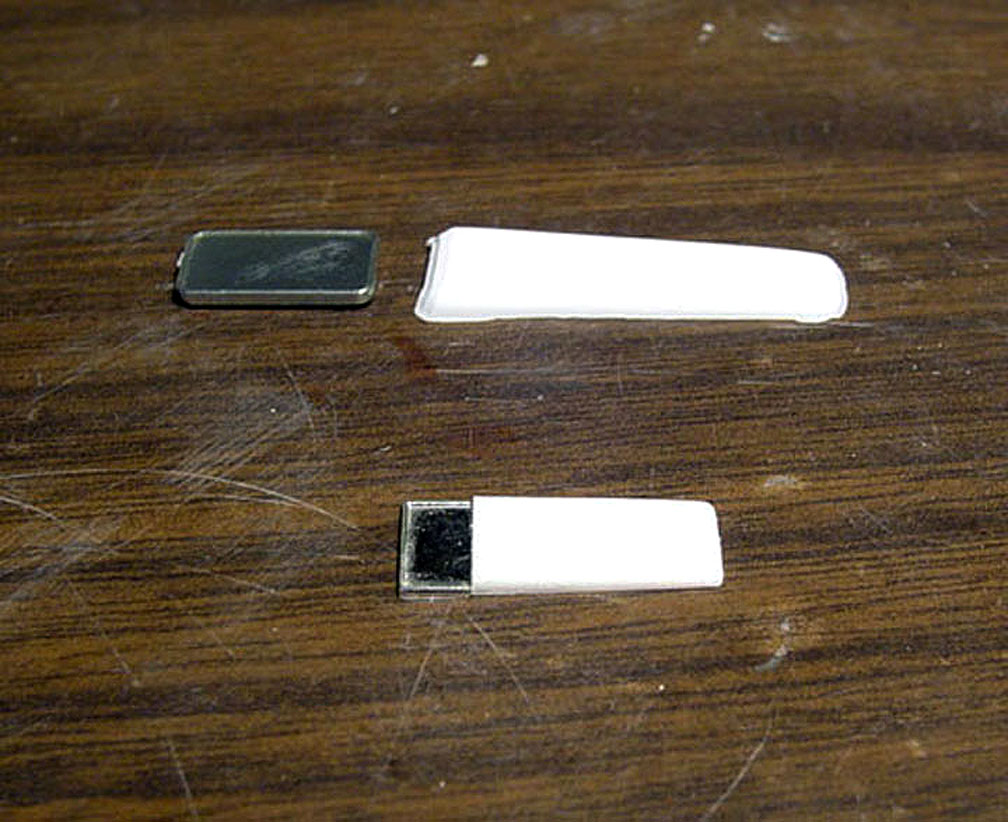

The '67 Buick skylark G/S 400 had 2 scoops on the hood..... Were going to try to replicate these.

The '67 Buick skylark G/S 400 had 2 scoops on the hood..... Were going to try to replicate these.

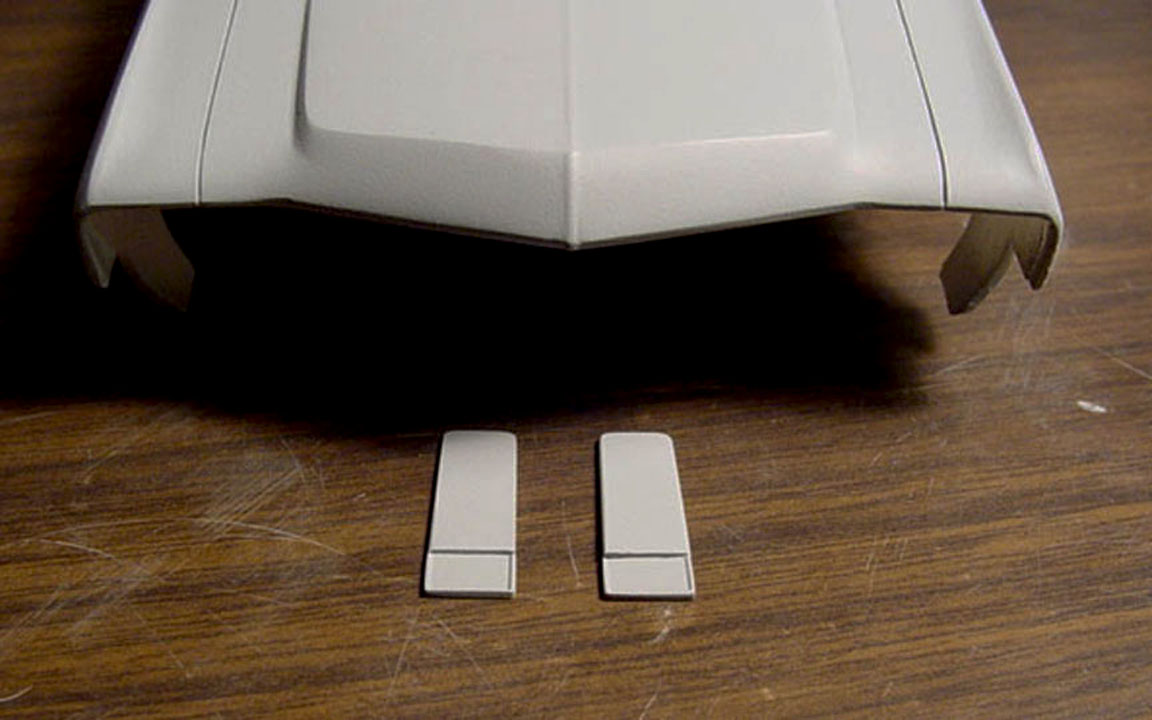

Starting with 2 parts box white scoops and 2 chrome step plates from a truck.....They were reshaped.

Starting with 2 parts box white scoops and 2 chrome step plates from a truck.....They were reshaped.

The 2 pieces are looking very close to the scoops needed.

The 2 pieces are looking very close to the scoops needed.

Scoops will be made separate from the hood.

Scoops will be made separate from the hood.

SIDE VENTS

After spending 3 days on trying to come up with a part I could use to make the side vents,

After spending 3 days on trying to come up with a part I could use to make the side vents,

I decided to use a part of a Ford Thunderbolt grill. Then plastic strip was added to the sides to make it look like it is incased.

The vents were glued to the body and a piece of plastic strip was added all around both of the 2 vents.

The vents were glued to the body and a piece of plastic strip was added all around both of the 2 vents.

WHEEL WELL TRIM

Wheel well trim was added using 1/2 round and after spraying primer, the cleaning up process begins.

Wheel well trim was added using 1/2 round and after spraying primer, the cleaning up process begins.

New molding on the rocker panels and rear wheel well trim was added.

New molding on the rocker panels and rear wheel well trim was added.

All imperfections and defects were fixed and then the body was polished.

The '66 Buick Dash board was altered to better resemble a '67 Buick.

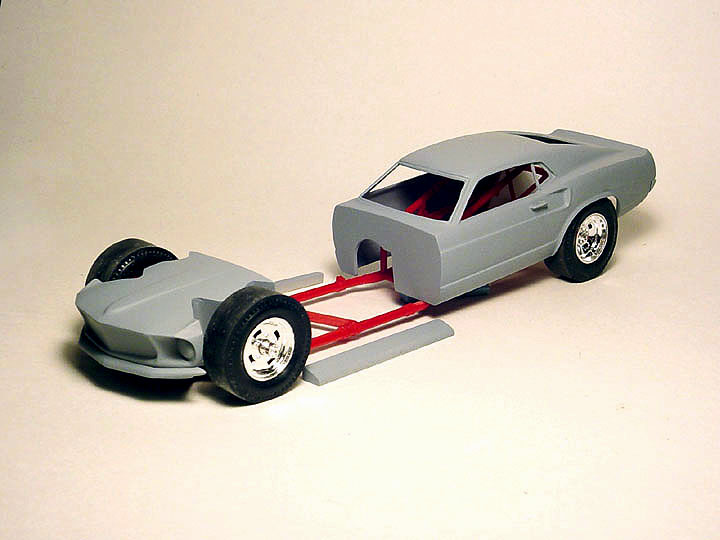

Gary

Weckesser's

MACH

IV Mustang Dragster

Thanks to the help and permission of Gary & Jill Wekesser.

We were able to get all the proper dimensions and photos of the actual car

being built.

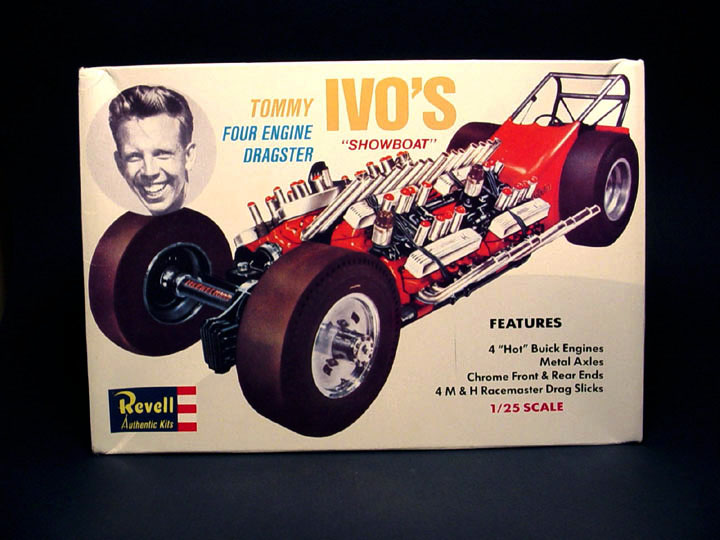

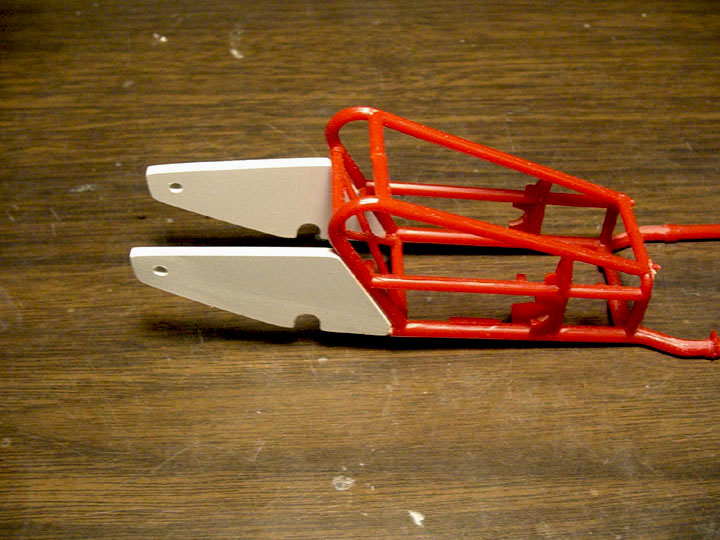

We built the model around a Revell Tommy Ivo Showboat chassis.................to be used as a donor kit.

We built the model around a Revell Tommy Ivo Showboat chassis.................to be used as a donor kit.

Although not a totally accurate chassis, it is a chassis

to work with or to work from, if designing a correct chassis.

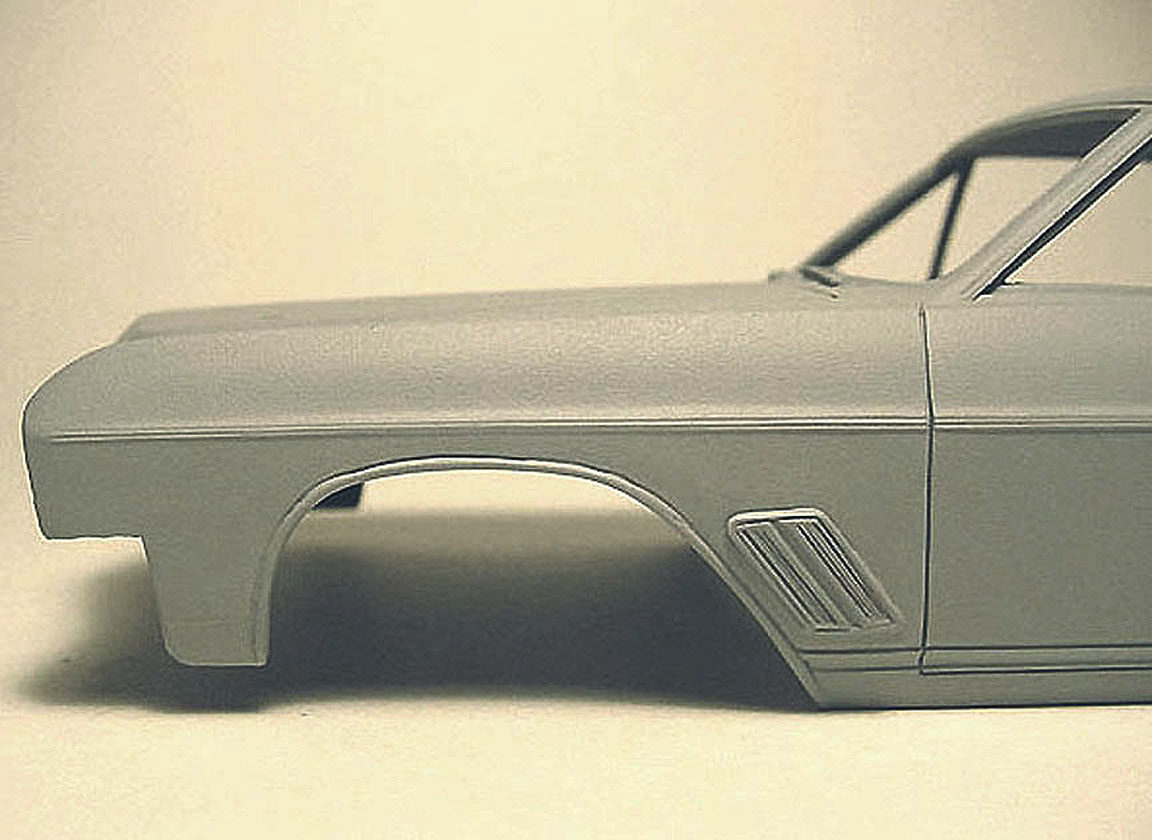

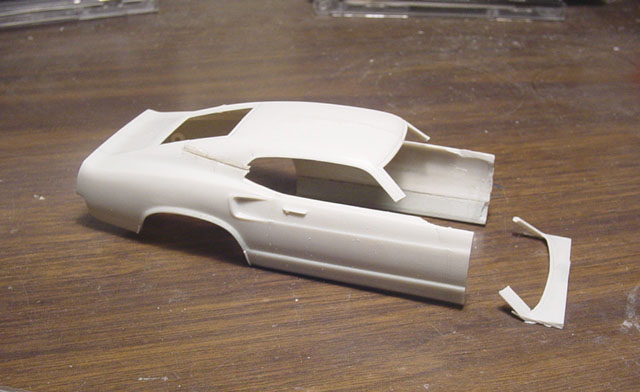

Starting with a 1/25 scale MPC '69 Mustang model, The rocker

panels need to be kicked out,

Using a '67 Mustang To rob the NEW rocker panels

from.

After the new rocker panels were in place, the rear wheel

wells were cut forward and the front clip was removed.

All door lines were filler with Ever coat putty & a "NEW"

rear wheel well lip was formed, creating a wider wheel well.

All moldings, emblems, wipers & marker lights were then

sanded off and cowl vents & all sink holes

All moldings, emblems, wipers & marker lights were then

sanded off and cowl vents & all sink holes

were filled in.

Carefully splitting the body in half and removing

14" scale inches from the length, it was then re glued.

Carefully splitting the body in half and removing

14" scale inches from the length, it was then re glued.

The A-pillar posts had 4" removed and set

back into the body 6 scale inches.

The A-pillar posts had 4" removed and set

back into the body 6 scale inches.

Cowl and A- Pillars installed. The door lines and rear wheel well were sanded smooth.

Cowl and A- Pillars installed. The door lines and rear wheel well were sanded smooth.

The front of the rear wheel well lips were re-shaped using putty.

The entire body was then sanded smooth.

The entire body was then sanded smooth.

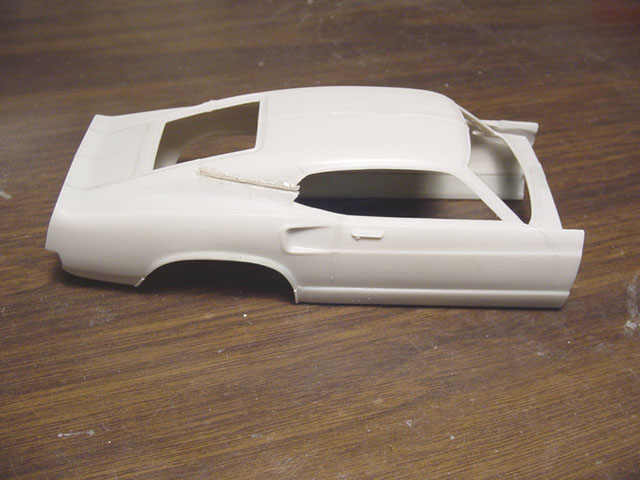

SO HERES WHERE IT WENT WRONG........... after looking at

the body , it still looked Too wide.

Calling Gary Weckesser, he informed me that the body was 18 inches thinner

(not 14").

So Its back to re-taping and removing another 4 inches from the length.....

AGAIN.

If it wasn't extremely painful the first time, it was a real kick in the pants

the 2nd time around.

But I'm a perfectionist, and if it's not right...... It's wrong.

The firewall was traced from the original Revell Showboat

model and re-fit to the new body,

The firewall was traced from the original Revell Showboat

model and re-fit to the new body,

this was done so the body would sit on the chassis properly.

The taillights were filled in and the rear splash panel was

molded to the body,

The taillights were filled in and the rear splash panel was

molded to the body,

along with an insert for the NEW shorter rear bumper.

In this photo, you can see the pivot points , so the body

can tilt up.

In this photo, you can see the pivot points , so the body

can tilt up.

At this point the firewall was reconstructed to fit the "SHOWBOAT" bell

housing. You can also see the new side windows.

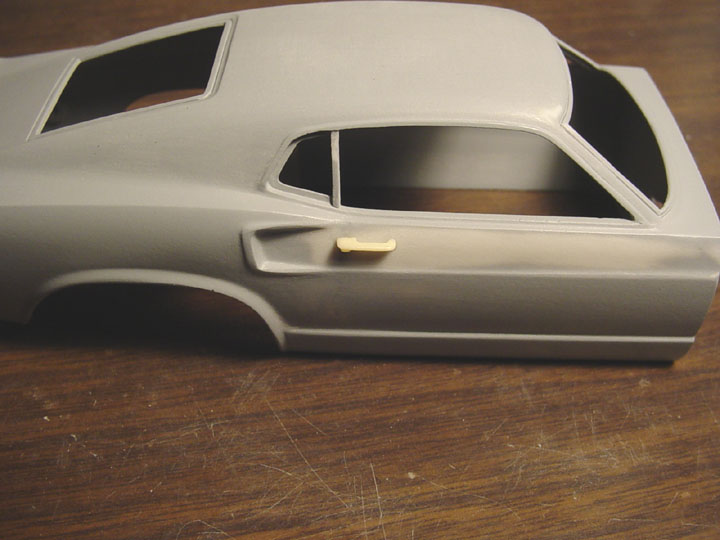

Door handles from a Revell Ford Thunderbolt were glued to the body and a

Door handles from a Revell Ford Thunderbolt were glued to the body and a

.010" was glued to the center of the door handle making them "SEMI-HOLLOW DOOR HANDLES".

The center of the door handles can be punched out making them completely hollow.

The front clip took so much thought, planning and work I

didn't have the time to do all the

The front clip took so much thought, planning and work I

didn't have the time to do all the

"In Progress" shots. Rather than give you a lengthily detailed list of all the labor done, I'll just let the

pictures do the talking.

The front and rear bumpers were altered at this time too.

Using a Revell Tommy Ivo Showboat 4 engine dragster model kit as a donor, we

had a major dilemma ?

Using a Revell Tommy Ivo Showboat 4 engine dragster model kit as a donor, we

had a major dilemma ?

The SHOIWBOAT has 4 Buick engines, but the MACH IV has 4

Ford engines.

It would be very costly for a builder to go out and purchase

4 Ford model kits to rob the engines from and it wouldn't be cost effective for us to cast an additional

4 ford engines to go with this kit, so we created a Ford 1-piece "HEAD, VALVE COVER & INJECTOR

MANIFOLD" set-up.

The Injection Ports were robbed from the Monogram BEER WAGON and plastic round tube will aid in adding our Injection Stacks.

We will make a mold of this one master, cast 7 others and then

make a mold of all 8 (shown in last photo).

We will make a mold of this one master, cast 7 others and then

make a mold of all 8 (shown in last photo).

These Heads can be added to the buick engine blocks, It's

not 100% correct, but it works ...............![]()

I felt It was necessary to

make frame extensions, to accommodate the longer Mustang body.....

I felt It was necessary to

make frame extensions, to accommodate the longer Mustang body.....

sounds

easy right ? ........ NOT AT ALL !

This was the most aggravating part of the project and took

3 attempts before it all fit perfectly !

The Rear axle had to fit correctly so the frame would sit level, while at

the same time

the holes for the hinges needed to make the body have the correct ride height

and correct body displacement.

DID

WE REALLY NEED TO MAKE THE FRAME EXTENSIONS.....NO,

but

I am first & foremost a model builder and this is what makes "SPEED

CITY" stand out from the rest.

WE CARE ABOUT THE BUILDER AND KEEP THAT IN MIND WHEN DOING A PROJECT.

Were not out to make a quick buck, We're out to design the best product on

the market !

This shows the body on its

pivots so the body can be raised.

This shows the body on its

pivots so the body can be raised.

Rocker panels can be mounted using cut pieces of a paper

clip and gluing to the frame.

Finally I made the 2 side rocker panels from 6 small sheets of .080" plastic sheet, Shaped and cut to size (no photo).

RIVIERA "WAGON MASTER"

4-ENGINE DRAGSTER

Unfortunately,

we only have these photos. These photos were taken before we created the "IN PROGRESS" page.

BILL KRAFT RAMBLER

1965 AMC MARLIN A.W.B. Funny Car

I just recently found these 2 photos today (8-26-2020). This master was made back in 2007 Before I had the "IN PROGRESS" page.

I just recently found these 2 photos today (8-26-2020). This master was made back in 2007 Before I had the "IN PROGRESS" page.

Besides the rear wheel well being altered, notice that the front fender was also widened 4 scale inches.

A lot of extensive work went into that chassis and interior tub !

A lot of extensive work went into that chassis and interior tub !

Page 1

Page 2

Page

3

All rights reserved. Do not copy any Speed City Resin bodies or parts without permission and consent.